Co9S8/MoS2 composite material prepared by two-step method and application thereof to hydrogen separation reaction

A composite material and molybdenum salt technology, applied in the field of materials and energy, can solve the problems of not using hydrogen production technology, cumbersome preparation steps, environmental pollution, etc., achieve important economic value and social significance, increase specific surface area, and improve catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In a typical embodiment of the present invention, there is provided a kind of above-mentioned Co 9 S 8 / MoS 2 A method for preparing a composite material, the method comprising the following steps:

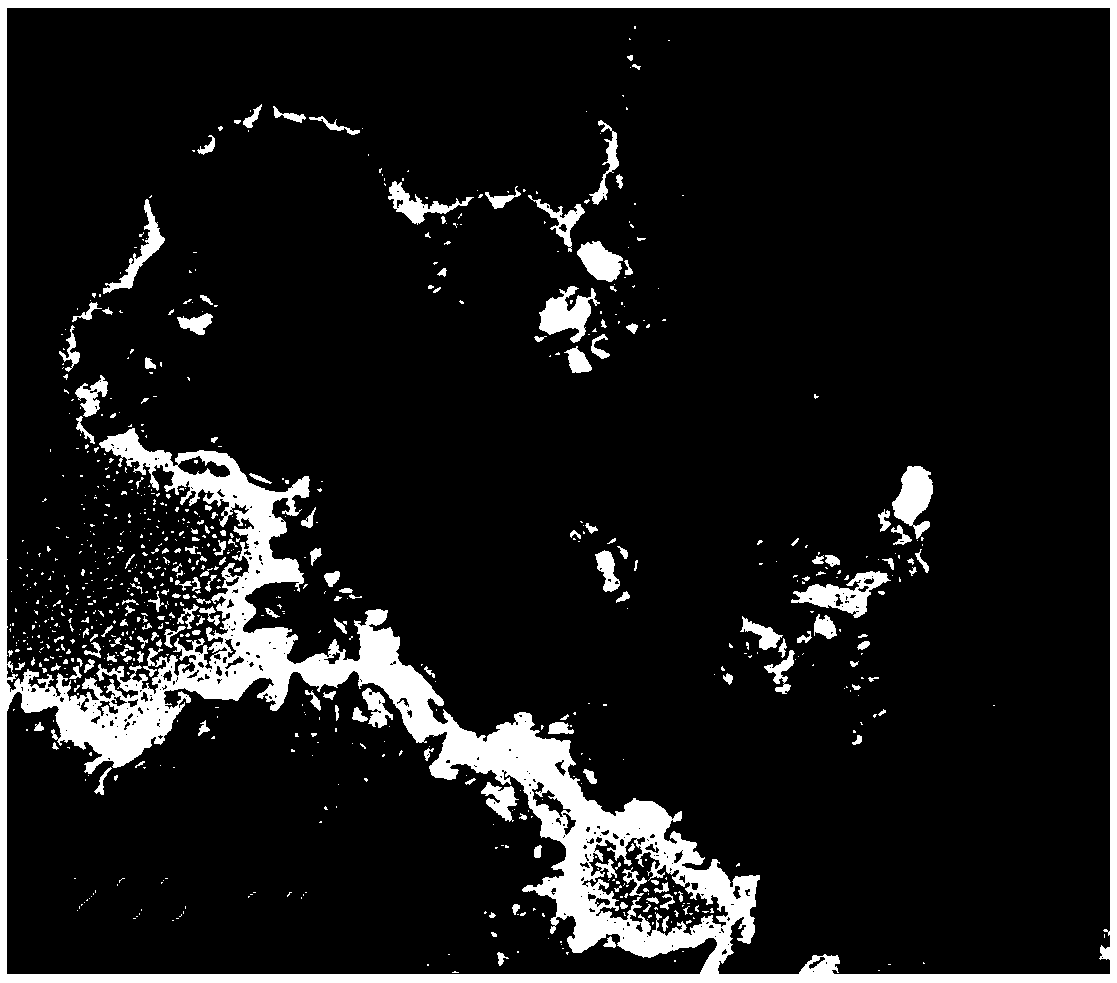

[0030] (1)Co 9 S 8 Preparation of hollow sphere precursor: Cobalt salt, glutathione, and thiourea were mixed, then hydrothermally treated, and the product was collected and dried to obtain Co with a hollow sphere structure. 9 S 8 Precursor; Co prepared by this method 9 S 8 The size of the hollow spheres is uniform and the yield is high. No pollution to the environment during the preparation process;

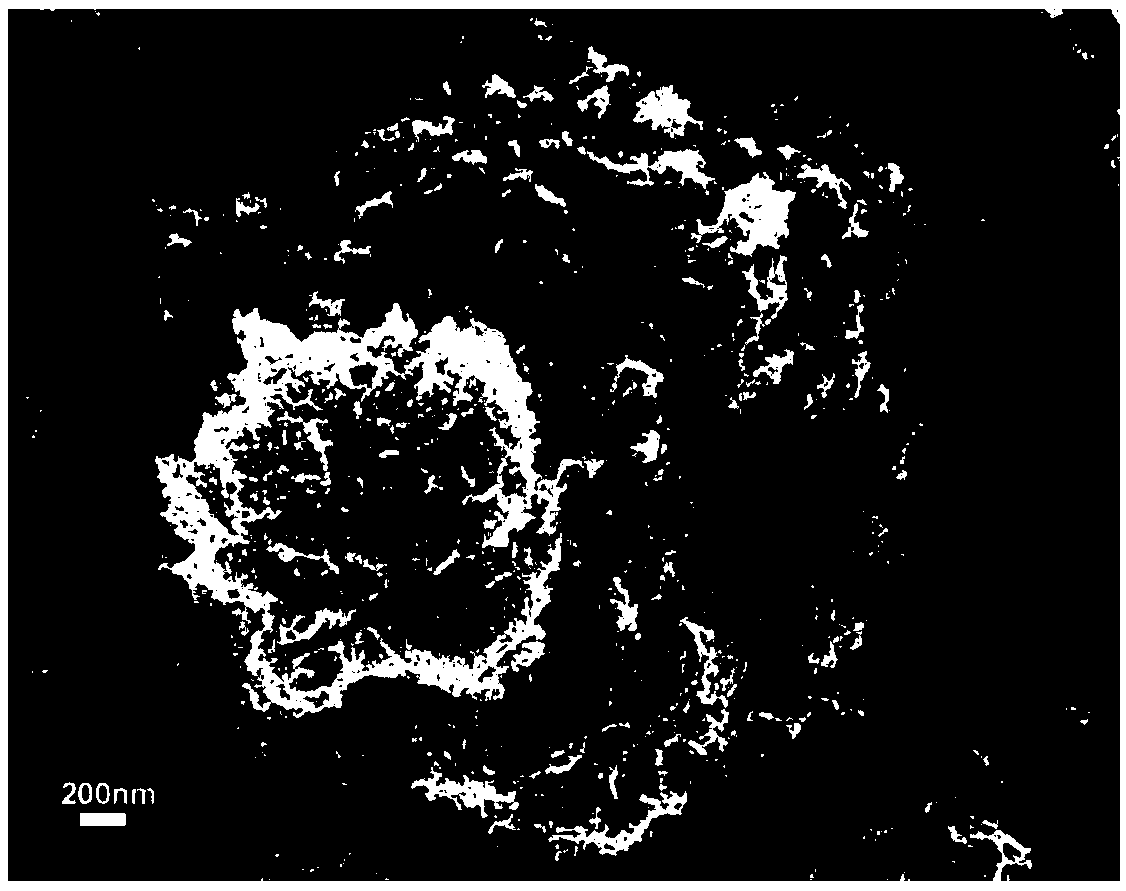

[0031] (2)Co 9 S 8 / MoS 2 Precursor preparation: take Co 9 S 8 The precursor is placed in a solution of molybdenum salt and L-cysteine for hydrothermal treatment, and the product is collected and dried to obtain MoS 2 Nanoflowers grow on hollow spheres Co 9 S 8 on the precursor;

[0032] (3)Co 9 S 8 / MoS 2 Preparation: Co 9 S 8 / MoS 2 The precursor is ...

Embodiment 1

[0044] Weigh 0.48g Co(CH 3 COO) 2 4H 2 O, after mixing 0.15g thiourea and 0.0591g glutathione, conduct hydrothermal treatment and heat at 180°C for 6h. After heating, the material was centrifuged and dried to obtain Co 9 S 8 Precursor. Take 20mg of Co 9 S 8 Precursor is base, placed in 45mg (NH 4 ) 2 MoS 4 and 303mgL-cysteine mixed solution, heat treatment at 200°C for 24h, after heating, centrifuge, rinse and dry to collect Co 9 S 8 / MoS 2 The precursor was then placed in a tube furnace for calcination, and then heated to 600 °C for 2 h under an argon atmosphere to obtain Co 9 S 8 / MoS 2 . The electrochemical catalytic performance of the catalyst was tested in 1.0mol / L KOH solution with a conventional three-electrode system. Preparation of working electrode: Take 10mg of powder catalyst and add it to 0.05mL 5w / w% Nafion solution, ultrasonically disperse, the system is in the form of ink, use a pipette to draw 5μL dropwise on the 4cm 2 The working electrode...

Embodiment 2

[0050] Weigh 0.96g Co(CH 3 COO) 2 4H 2 O, after mixing 0.3g thiourea and 0.1182g glutathione, carry out hydrothermal treatment and heat at 140°C for 12h. After heating, the material was centrifuged and dried to obtain Co 9 S 8 Precursor. Take 60mg of Co 9 S 8 The precursor is used as the base, placed in 90mg (NH 4 ) 2 MoS 4and 606mgL-cysteine mixed solution, heat treatment at 200°C for 24h, after heating, centrifuge, rinse and dry to collect Co 9 S 8 / MoS 2 The precursor was then placed in a tube furnace for calcination, and then heated to 600 °C for 2 h under an argon atmosphere to obtain Co 9 S 8 / MoS 2 . The electrochemical catalytic performance of the catalyst was tested in 1.0mol / L KOH solution with a conventional three-electrode system. Preparation of the working electrode: Take 10 mg powder catalyst and add it to 0.05 mL 5% Nafion solution, ultrasonically disperse it, the system is in the form of ink, use a pipette to draw 5 μL dropwise on the 4 cm 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com