Exhaust gas treatment equipment used for industrial environmental protection

A waste gas treatment equipment and environmental protection technology, applied in the direction of climate change adaptation, climate sustainability, human health protection, etc., can solve the problems of inability to filter larger particles of waste gas, inability to filter air twice, and inability to save energy, etc., to achieve convenient The effect of treating waste gas, preventing air pollution, and facilitating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

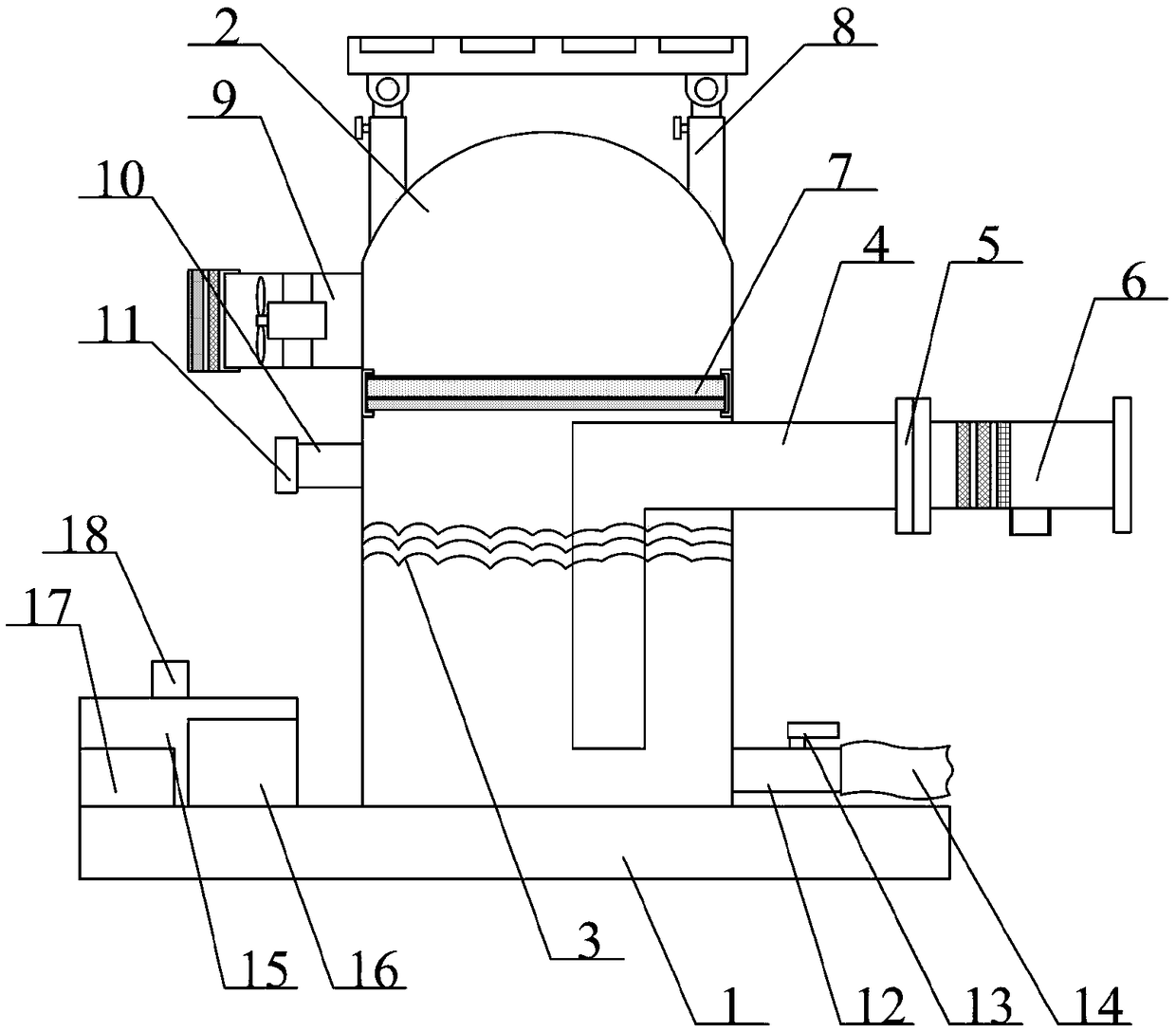

[0042] as attached figure 1 to attach Figure 5 shown

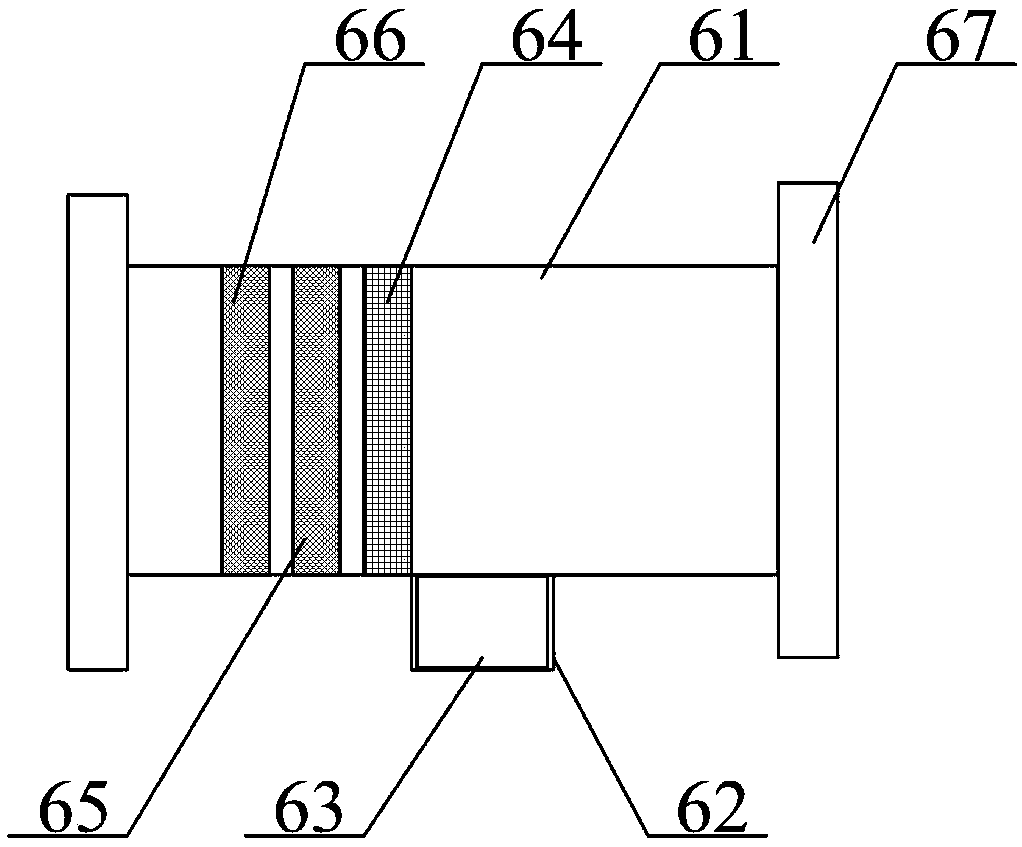

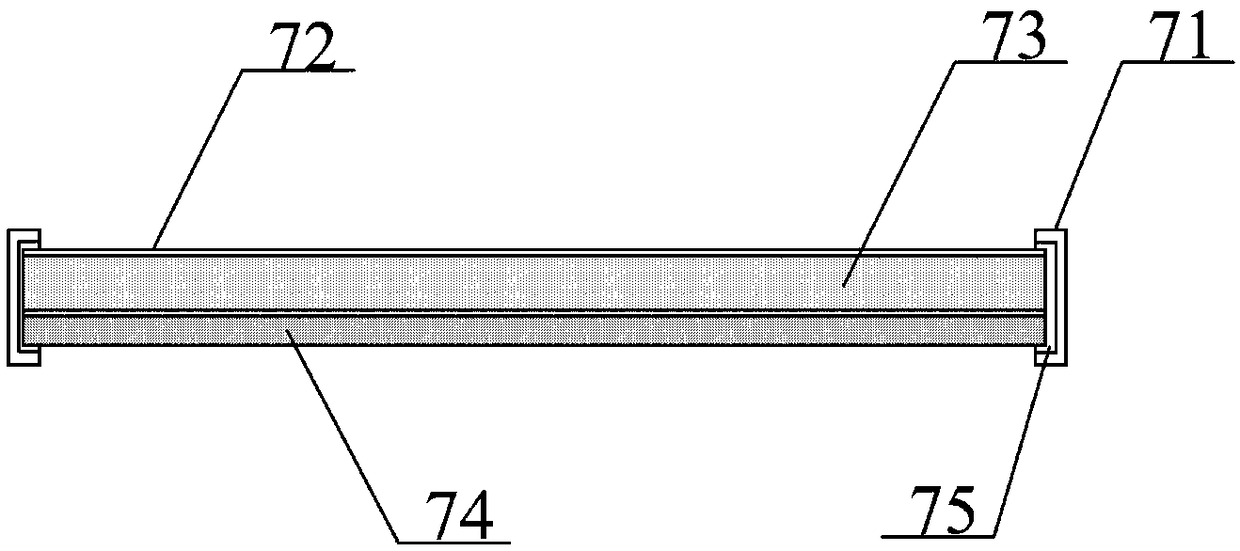

[0043] The invention provides a waste gas treatment device for industrial environmental protection, which includes a base 1, a filter tank 2, filtered water 3, an air intake pipe 4, a fixed flange 5, an air intake dust removal pipe structure 6, and an odor adsorption plate structure 7, which can be adjusted Environmental protection board structure 8, air outlet filter pipe structure 9, water inlet pipe 10, sealing cap 11, water discharge pipe 12, manual valve 13, water discharge belt 14, fixed box 15, battery 16, photovoltaic converter 17 and exhaust switch 18, the The filter tank 2 is bolted to the middle position of the upper end of the base 1; the filtered water 3 is injected into the filter tank 2; the air inlet pipe 4 runs through the middle position of the right wall of the filter tank 2; the fixed flange 5 Welded at the right end of the air intake pipe 4; the air intake dust removal pipe structure 6 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com