Cable-stayed bridge steel girder and bridge deck slab combined hoisting equipment and hoisting method

A combined hoisting and bridge deck technology, which is applied in the direction of cable-stayed bridges, bridge construction, hoisting equipment braking devices, etc., can solve the problems that the bridge deck cannot be hoisted, it is located outside the cable stays, and affects the construction speed, etc., and the installation speed can be achieved. Fast, convenient construction, and the effect of controlling construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

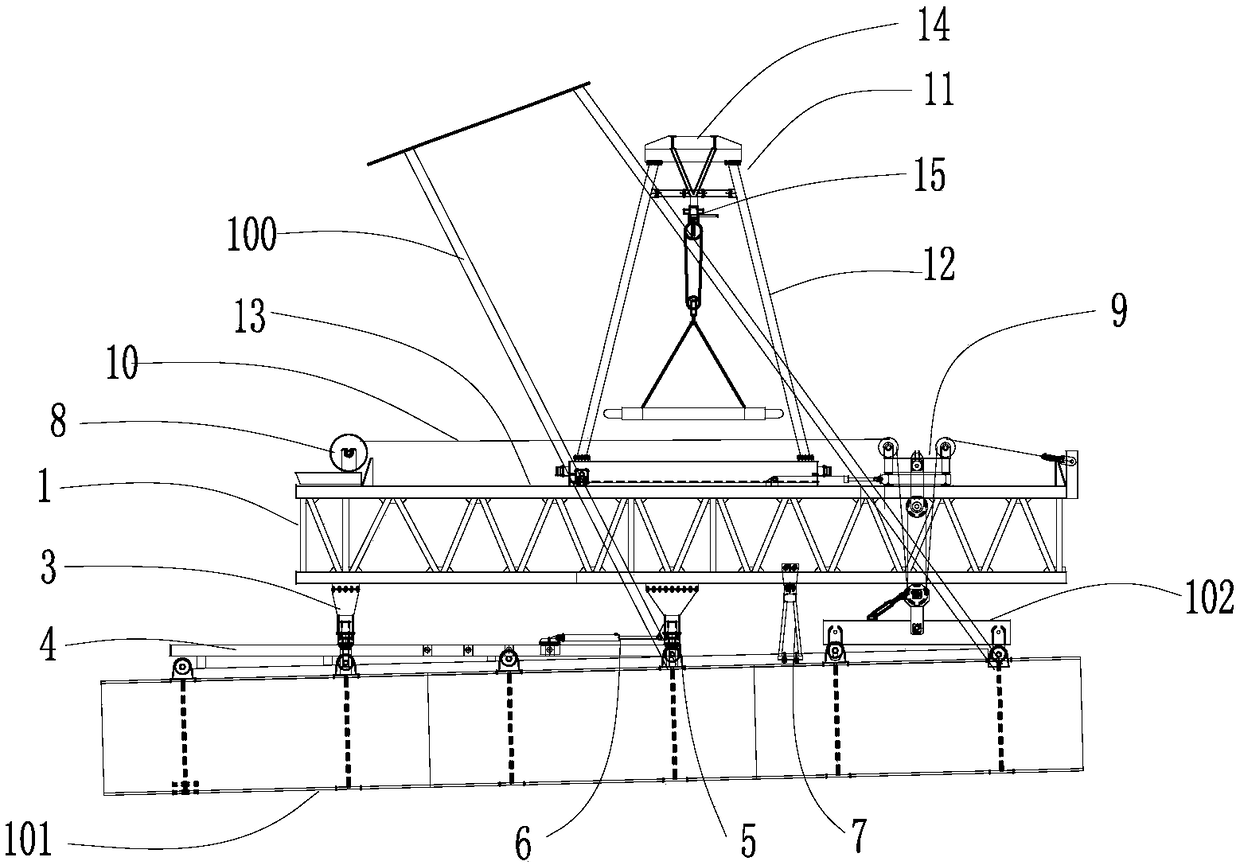

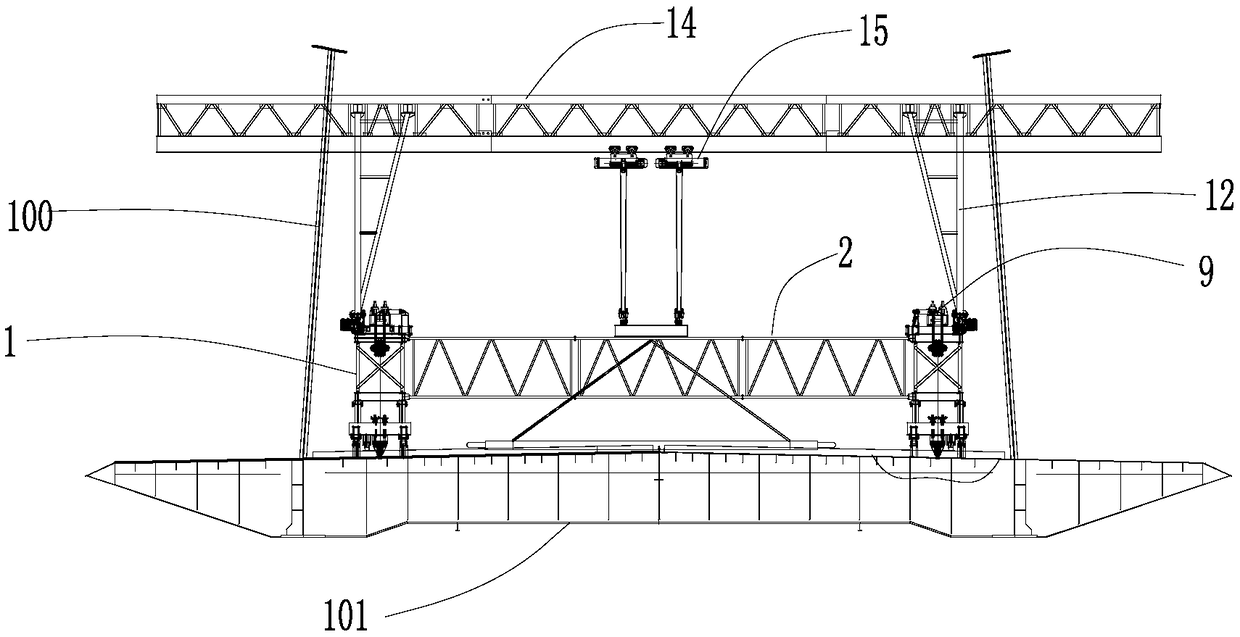

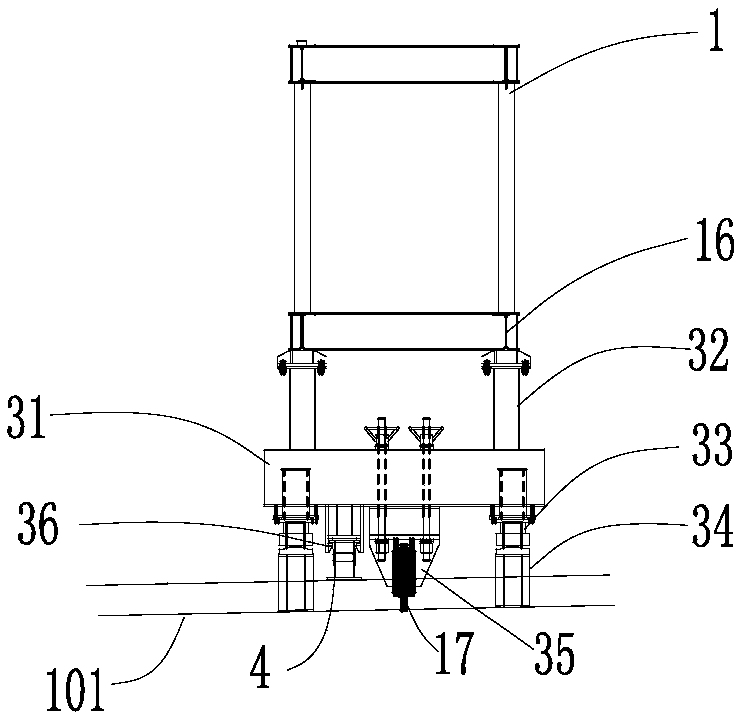

[0028] Such as figure 1 , figure 2 As shown, the combined hoisting equipment of a cable-stayed bridge steel girder and bridge deck provided by the present invention includes a deck crane for hoisting the steel girder. The main girder 1 on the inner side of the bridge stay cable 100, the front end and the rear end of the two main girders 1 are respectively connected by the front beam and the rear beam 2, and the main beam 1, the front beam and the rear beam 2 are all truss structures. There are two upper chords and two lower chords; the rear end of the bottom of each main girder is provided with a rear outrigger 3, and the upper end of the rear outrigger 3 is connected to the lower chord of the main girder 1 by bolts, and the lower end of the rear outrigger is supported in the direction of the bridge. On the deck crane slide rail 4 on the top surface of the steel girder 101, and anchored with the lugs on the steel girder 101; the middle of each main girder bottom is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com