Alkali-resistant glass fiber mesh cloth

A technology of alkali-resistant glass fiber and glass fiber yarn, which is applied in the field of mesh cloth, can solve the problems of high temperature resistance, poor alkali resistance and erosion resistance, insufficient strength, and uneven surface of mesh cloth, so as to improve the burning resistance Corrosion performance and mechanical erosion resistance, high temperature resistance, low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

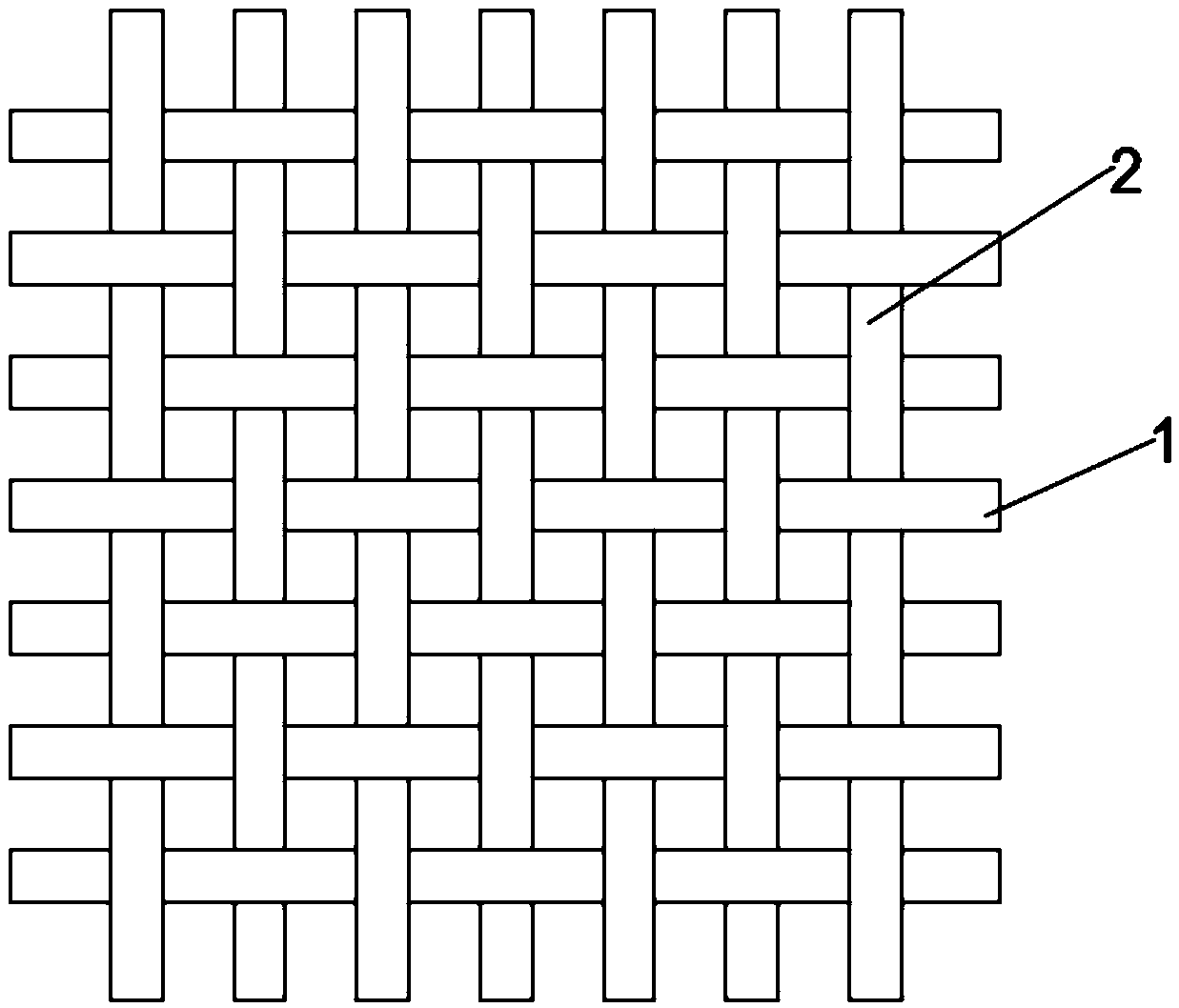

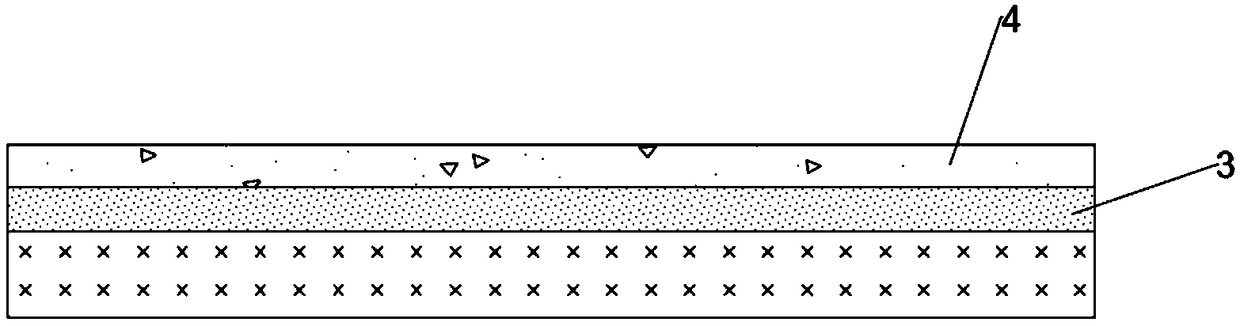

[0020] An alkali-resistant glass fiber mesh cloth, the alkali-resistant glass fiber mesh cloth is woven from warp threads and weft threads, all warp threads 1 are arranged longitudinally at equal intervals, all weft threads 2 are equidistantly arranged horizontally, and each warp thread 1 is aligned with all weft threads 2 Interweaving; all warps 1 and wefts 2 are glass fiber yarns, and the glass fiber yarns include several monofilaments, and the diameter of each monofilament is 7 μm; the thickness of the alkali-resistant glass fiber mesh cloth is 0.2mm; The linear density of the alkali glass fiber yarn is 30tex, and the outer surface of the alkali-resistant glass fiber mesh cloth is coated with an adhesive layer 3, and the outer surface of the adhesive layer 3 is coated with an alkali-resistant layer 4, and the outer surface of the adhesive layer 3 is coated with an alkali-resistant layer 4. It can make the alkali-resistant layer 4 and the surface of the alkali-resistant glass...

Embodiment 2

[0030] An alkali-resistant glass fiber mesh cloth, the alkali-resistant glass fiber mesh cloth is woven from warp threads and weft threads, all warp threads 1 are arranged longitudinally at equal intervals, all weft threads 2 are equidistantly arranged horizontally, and each warp thread 1 is aligned with all weft threads 2 Interweaving; all warps 1 and wefts 2 are glass fiber yarns, and the glass fiber yarns include several monofilaments, and the diameter of each monofilament is 10 μm; the thickness of the alkali-resistant glass fiber mesh cloth is 0.7mm; The linear density of the alkali glass fiber yarn is 260tex, and the outer surface of the alkali-resistant glass fiber mesh cloth is coated with an adhesive layer 3, and the outer surface of the adhesive layer 3 is coated with an alkali-resistant layer 4, and the outer surface of the adhesive layer 3 is coated with an alkali-resistant layer 4. It can make the alkali-resistant layer 4 and the surface of the alkali-resistant gla...

Embodiment 3

[0040] An alkali-resistant glass fiber mesh cloth, the alkali-resistant glass fiber mesh cloth is woven from warp threads and weft threads, all warp threads 1 are arranged longitudinally at equal intervals, all weft threads 2 are equidistantly arranged horizontally, and each warp thread 1 is aligned with all weft threads 2 Interweaving; all warps 1 and wefts 2 are glass fiber yarns, and the glass fiber yarns include some monofilaments, and the diameter of each monofilament is 9 μm; the thickness of the alkali-resistant glass fiber mesh cloth is 0.4mm; The linear density of the alkali glass fiber yarn is 220tex, and the outer surface of the alkali-resistant glass fiber mesh cloth is coated with a binder layer 3, and the outer surface of the binder layer 3 is coated with an alkali-resistant layer 4, and the outer surface of the binder layer 3 is coated with an alkali-resistant layer 4, and the outer surface of the binder layer 3 is coated with an alkali-resistant layer 4. It can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com