Building interior wall insulation coating and preparation method thereof

A technology for thermal insulation coatings and buildings. It is applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc. It can solve problems such as weakened bonding performance, coating film peeling, and inability to use, so as to improve stability. Strong bonding performance and enhanced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

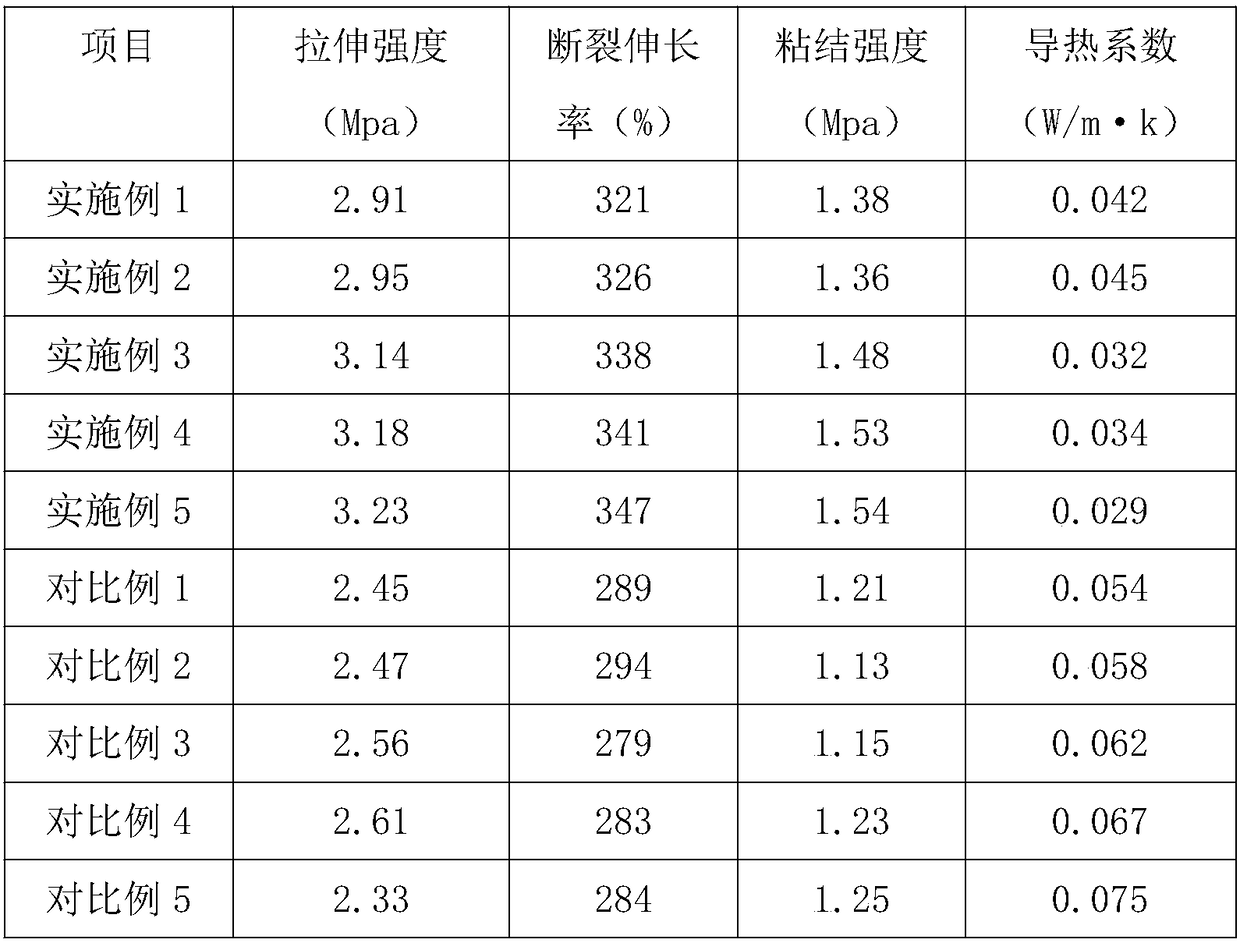

Examples

Embodiment 1

[0035] This embodiment relates to a kind of thermal insulation coating for building interior walls, comprising the following raw materials in parts by weight:

[0036] 70 parts of epoxy resin emulsion, 40 parts of acrylate emulsion, 16 parts of brucite fiber, 25 parts of white carbon black, 5 parts of glyceryl monostearate, 3 parts of sodium tripolyphosphate, 1 part of table salt, 10 parts of silicon dioxide Parts, 6 parts of octamethylcyclotetrasiloxane, 8 parts of hydroxypropyl methylcellulose, 10 parts of paraffin, 3 parts of sodium stearate, 4 parts of stearic acid, 6 parts of propylene glycol methyl ether acetate, chlorinated 3 parts of tributyltin.

[0037] Wherein, the white carbon black is fumed white carbon black, and the particle size of the fumed white carbon black is 5 nm.

[0038] Wherein, the particle size of the brucite fiber is 400 mesh.

[0039] This embodiment also relates to a preparation method of building interior wall thermal insulation coating, compris...

Embodiment 2

[0052] This embodiment relates to a kind of thermal insulation coating for building interior walls, comprising the following raw materials in parts by weight:

[0053] 80 parts of epoxy resin emulsion, 50 parts of acrylate emulsion, 22 parts of brucite fiber, 30 parts of white carbon black, 8 parts of glyceryl monostearate, 10 parts of sodium tripolyphosphate, 5 parts of table salt, 16 parts of silicon dioxide 14 parts of octamethylcyclotetrasiloxane, 12 parts of hydroxypropyl methylcellulose, 14 parts of paraffin, 6 parts of sodium stearate, 8 parts of stearic acid, 10 parts of propylene glycol methyl ether acetate, 7 parts of tributyltin.

[0054] Wherein, the white carbon black is fumed white carbon black, and the particle size of the fumed white carbon black is 15 nm.

[0055] Wherein, the particle size of the brucite fiber is 550 mesh.

[0056] This embodiment also relates to a preparation method of building interior wall thermal insulation coating, comprising the follo...

Embodiment 3

[0069] This embodiment relates to a kind of thermal insulation coating for building interior walls, comprising the following raw materials in parts by weight:

[0070] 72 parts of water-based epoxy resin emulsion, 42 parts of acrylate emulsion, 18 parts of brucite fiber, 27 parts of white carbon black, 6 parts of glyceryl monostearate, 5 parts of sodium tripolyphosphate, 2 parts of table salt, silicon dioxide 12 parts, 8 parts of octamethylcyclotetrasiloxane, 9 parts of hydroxypropyl methylcellulose, 11 parts of paraffin, 4 parts of sodium stearate, 5 parts of stearic acid, 7 parts of propylene glycol methyl ether acetate, chlorine 4 parts of tributyltin.

[0071] Wherein, the white carbon black is fumed white carbon black, and the particle size of the fumed white carbon black is 5 nm.

[0072] Wherein, the particle size of the brucite fiber is 400 mesh.

[0073] This embodiment also relates to a preparation method of building interior wall thermal insulation coating, compri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com