Integrated silk feeding machine

A wire feeder and filament technology, which is used in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of long tailing of the cutting surface, uneven cutting speed and cutting surface, and enterprise loss, etc. Effects of brittleness or toughness, improved cutting efficiency, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

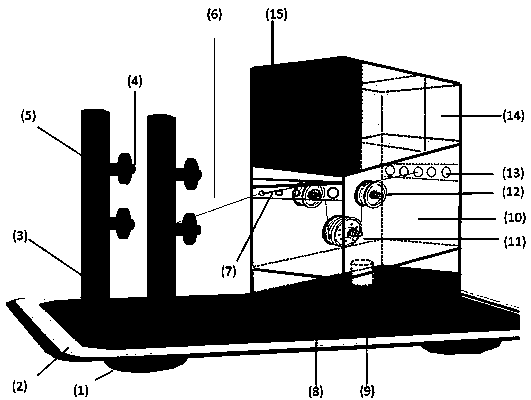

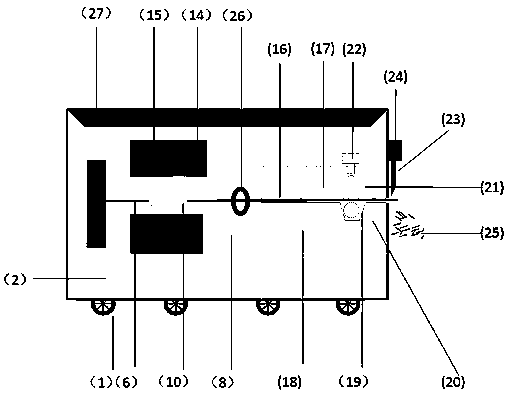

[0033] An integrated wire feeder. The wire feeder is divided into two parts: the outer shell and the inner shell. The outer shell is equipped with a PC computer terminal and a wire cutting mechanism, and the inner shell is sequentially equipped with a wire feeding mechanism, a cooling-infusion Mechanism, wire drawing mechanism, wire pressing mechanism, the computer terminal detects and controls the cooling-infusion mechanism and the wire pressing mechanism, the wire cutting mechanism is located at the outlet end of the wire pressing mechanism, and the diameter of the material wire is 0.1~5mm nylon or modified Nylon polymer, and the temperature of the wire at the outlet end of the wire pressing mechanism is 9-12 o C range.

[0034]Further, the wire feeding mechanism includes a plurality of parallel vertical beams (3) fixedly arranged on the support base plate (2), each vertical beam (3) fixes a plurality of support arms (4), and each support arm (4) Set up a wire reel (5), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com