A hydraulic system for controlling the boom suspension of a high-ground-clearance sprayer

A hydraulic system and sprayer technology, which is applied in the field of hydraulic systems, can solve the problems that the hydraulic system of the spray boom suspension is difficult to pressure shock, reduce the stability of the spray boom and spray accuracy, and shorten the service life of the spray boom, so as to reduce the energy of the system Loss, improvement of dynamic characteristics, effect of attenuating boom vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

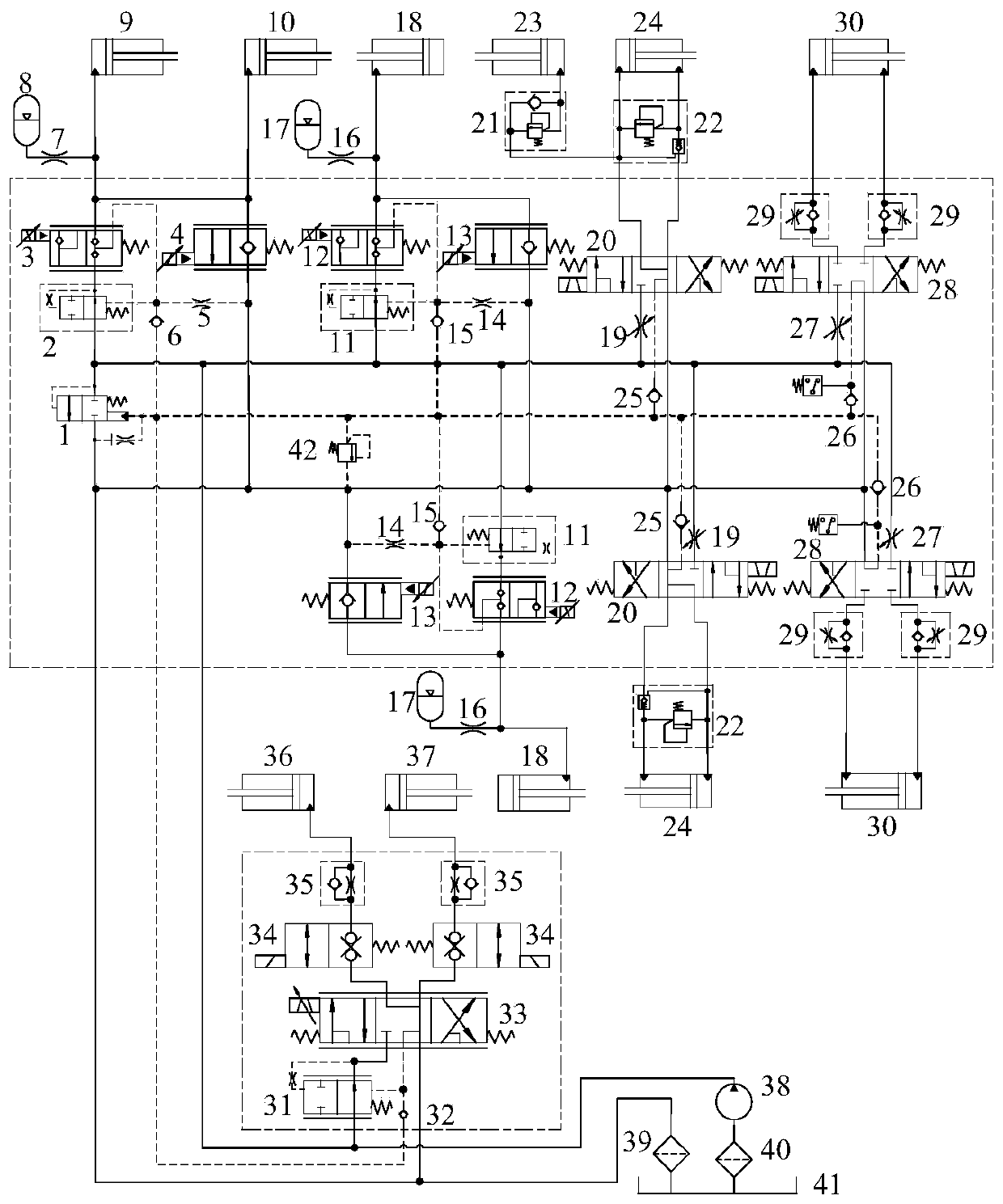

[0055] like figure 1 As shown, a high ground clearance sprayer boom suspension control hydraulic system includes a differential pressure relief valve 1, a hydraulic pump 38, a lifting hydraulic unit, a left boom folding profiling hydraulic unit, a right spray boom folding profiling hydraulic Unit and vertical active and passive suspension control hydraulic unit.

[0056] The lifting hydraulic unit includes a first differential pressure reducing valve 2, a first two-position three-way proportional directional control valve 3, a first two-position two-way proportional directional control valve 4, a first throttle hole 5, a first sensor Check valve 6, first lifting hydraulic cylinder 9 and second lifting hydraulic cylinder 10.

[0057] The oil outlet of the first differential pressure reducing valve 2 is connected to the oil inlet of the first two-positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com