Double-fed induction motor system direct torque controller capable of reducing torque ripple

A doubly-fed induction motor and torque controller technology, which is applied in the direction of generator control circuit, asynchronous generator control, control system, etc., can solve problems such as pulsation, torque pulsation, and stator flux linkage estimation accuracy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

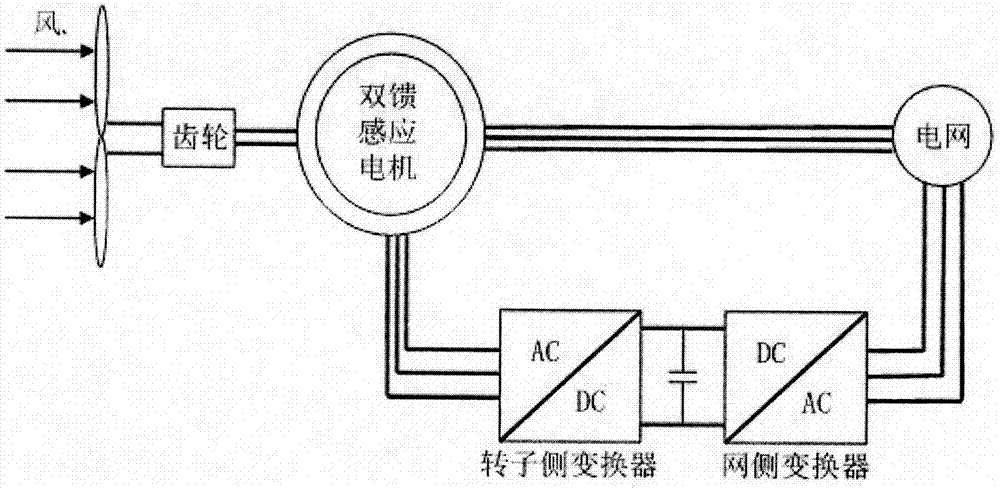

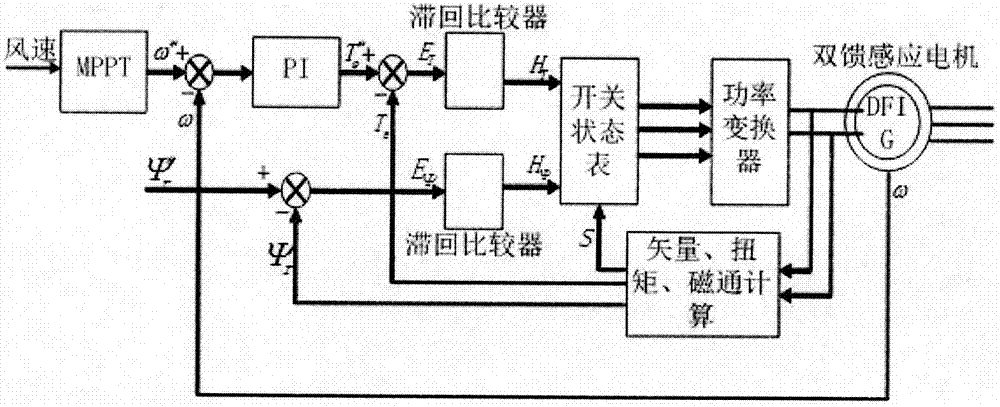

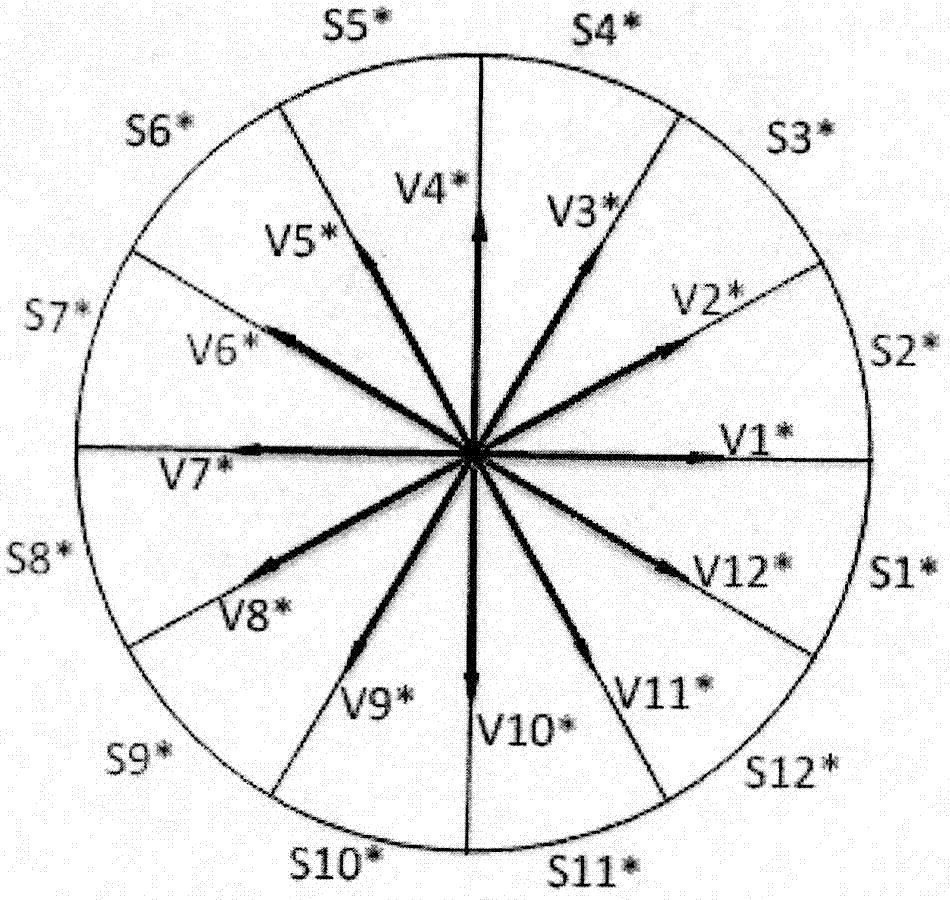

[0011] The content of the present invention will be described in detail below in conjunction with the accompanying drawings. At present, double-fed induction motors are mainly used in wind power generation systems. figure 1 It is the topological structure diagram of wind power generation system based on doubly-fed induction motor. Among them, the stator winding of the double-fed induction motor is directly connected to the grid, and the rotor winding is connected to a back-to-back converter group. figure 2 It is the control block diagram of direct torque control in doubly-fed induction motor. The principle of direct torque control is to directly select the appropriate rotor voltage vector according to the rotor flux, torque error and rotor flux sector. from figure 2 As can be seen in , the reference value of torque T e * and the reference value Ψ of the rotor flux r * respectively with the corresponding estimated value T e with Ψ r Compare. T e * From the rotor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com