Flexible current collector battery and production method thereof

A flexible current collector and fluid battery technology, applied in electrolyte battery manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as hidden dangers of lithium-ion battery safety, fragmentation affecting the use effect, and affecting the quality of lithium-ion battery products. , to ensure the cycle effect and safety performance, solve the problem of easy tearing, and solve the effect of easy oxidation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] as attached figure 1 The shown flexible current collector 100 includes at least one polymer material layer 101 as a base layer; at least one porous ceramic layer 102 attached to the base layer; and at least one conductive coating 103 attached to the porous ceramic layer 102 .

[0050]In the above technical solution, the lithium ion battery product of the present invention uses a new material layer to replace the traditional metal matrix to make a lithium battery electrode current collector, which solves the problem of poor bonding between the traditional metal matrix current collector and the active material layer. For the use of flexible current collector electrodes, the peel strength between the flexible current collector and the active material is 3-6N / m compared with the peel strength between the metal matrix current collector and the active material is 0.2-1.5N / m. The binding force between the current collector and the active material layer is significantly improve...

Embodiment 2

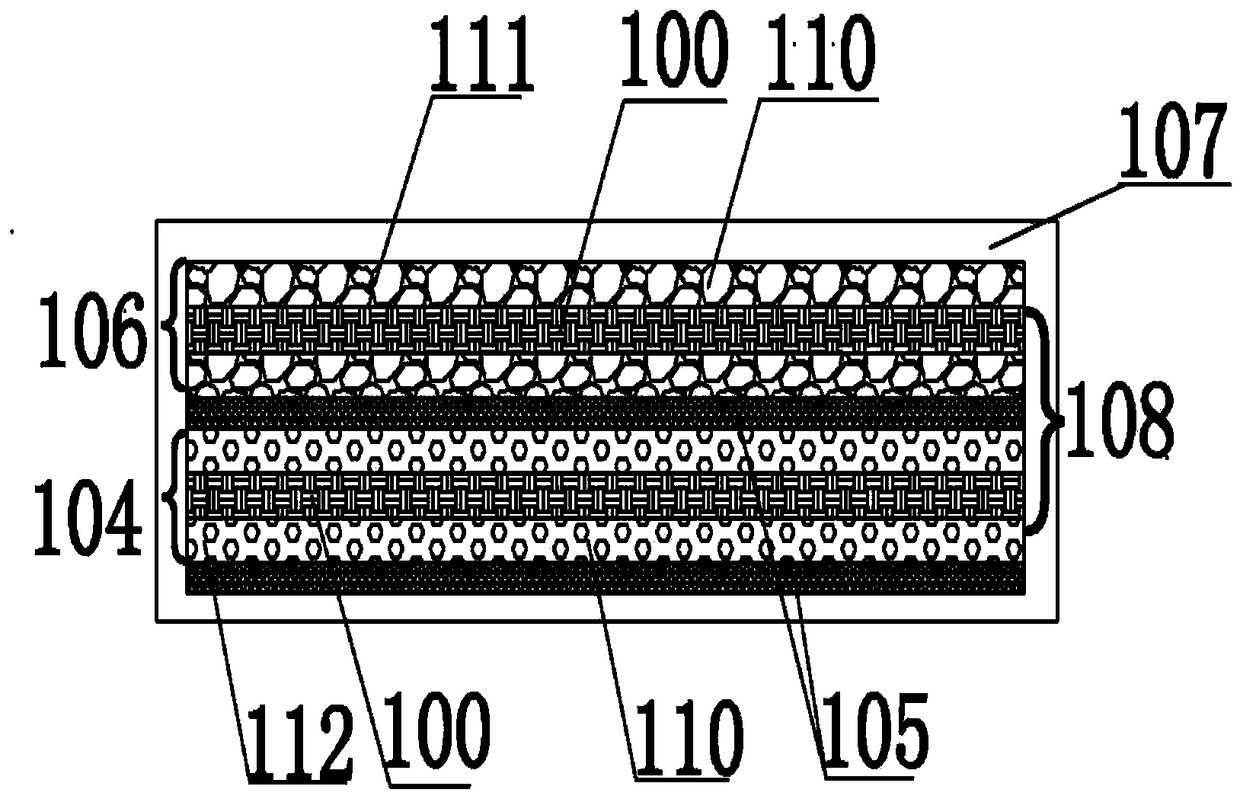

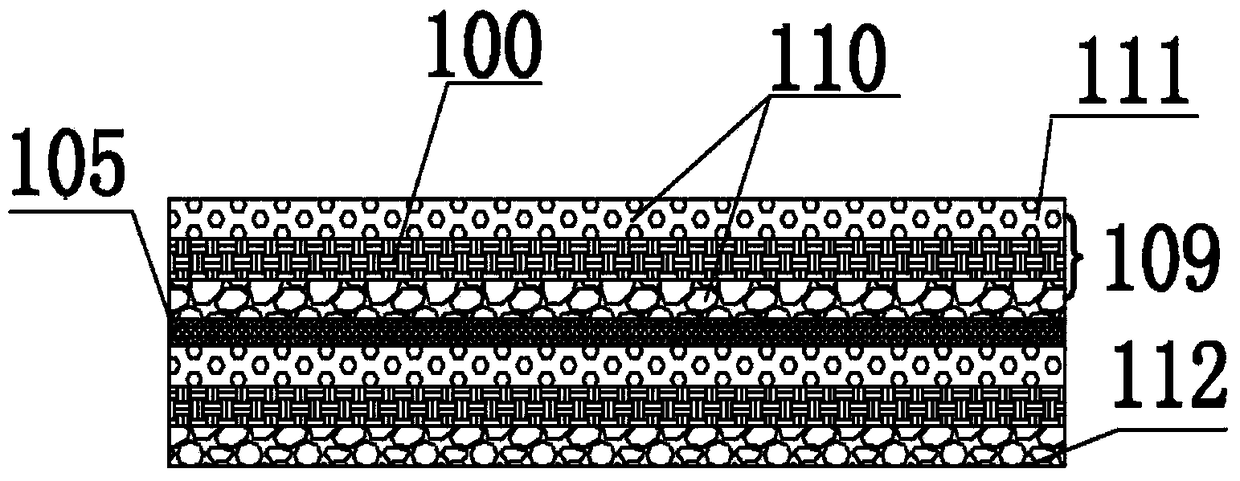

[0052] combined with figure 1 And attached figure 2 As shown, a flexible current collector battery: including at least one set of flexible current collector positive and negative electrodes 108; at least one diaphragm placed between the flexible current collector positive electrode 104 and the flexible current collector negative electrode 106; The electrolyte solution of the fluid electrodes 104, 106 and the diaphragm 105; and a battery case 107 covering the flexible current collector electrodes 104, 106, the diaphragm 105 and the electrolyte solution. The flexible current collector positive electrode 104 includes a flexible current collector 100 and two active material layers 110 attached thereon; the flexible current collector negative electrode 106 includes a flexible current collector 100 and two active material layers 110 attached thereon. The flexible current collector positive and negative electrodes 108 include two flexible current collectors 100 and a set of opposit...

Embodiment 3

[0057] The preparation method of the flexible current collector 100 is combined with the attached figure 1 As shown, a polymer material layer 101 is prepared from a polymer material PE with a thickness of 3 μm and a porosity of 25% as the base of the flexible current collector 100 . Porous ceramic alumina is coated on both surfaces of the polymer material layer 101 to a thickness of 200 nm to obtain a porous ceramic layer 102 . Mix the conductive carbon black slurry and nanotubes to obtain a conductive slurry with a concentration of 6%, and coat the porous ceramic layer 102 with a conductive coating 103 to obtain a double-sided flexible current collector 100 .

[0058] The areal density of the flexible current collector 100 prepared by the above scheme is 0.1 mg / cm 2 , porosity 25%, better than metal current collector, for example: aluminum current collector 3mg / cm 2 , porosity 0%; copper current collector 6mg / cm 2 , Porosity 0%. Using the flexible current collector prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com