Preparation method of dynamic graph capable of moving in certain direction based on microlens array and micro-graphic array

A technology of micro-lens array and micro-graphics, which is applied in the direction of lens, optics, instruments, etc., can solve the problem of single and limited movement of patterns, and achieve the effect of enhancing the visual experience of human eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

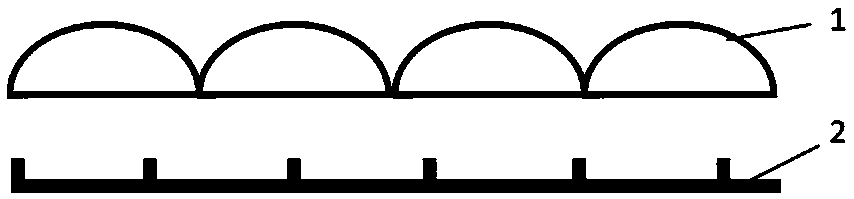

[0018] In this embodiment, the dot array pattern and the "A" array pattern are designed and prepared, and glued together to obtain the microstructure of the two patterns moving orthogonally, as shown in the attached figure 1 shown. Specifically follow the steps below:

[0019] (1) Design and preparation of microlens array

[0020] First, according to the periodic formula of moiré:

[0021]

[0022] Determine the period of dynamic graphics; where T is the period of dynamic graphics, D is the period of microlens array, d is the period of micrographic array, θ is the angle between micrographic array and microlens array, and the period of microlens array is selected here as 50 μm , as attached figure 2 shown. Then determine that the sagittal height of the microlens is 5 μm, and then the radius of curvature of the microlens can be obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com