Shredded paper processing and paper environment-friendly pencil production integrated machine

An all-in-one machine and paper-based technology, which is applied in non-mechanical pencils, fiber raw material processing, papermaking, etc., can solve problems such as poor recycling results, and achieve the effects of low cost, wide application range, great application prospects and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

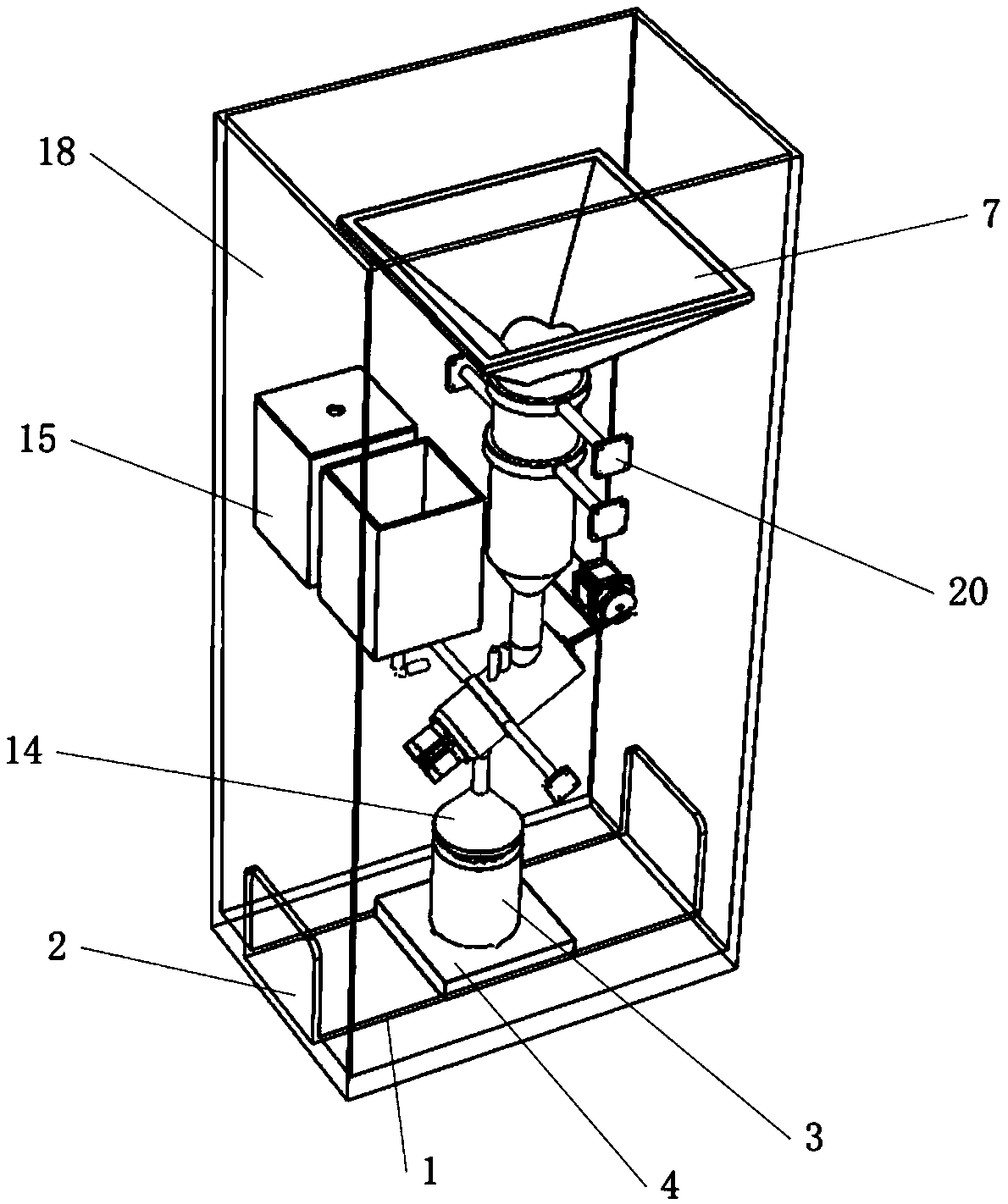

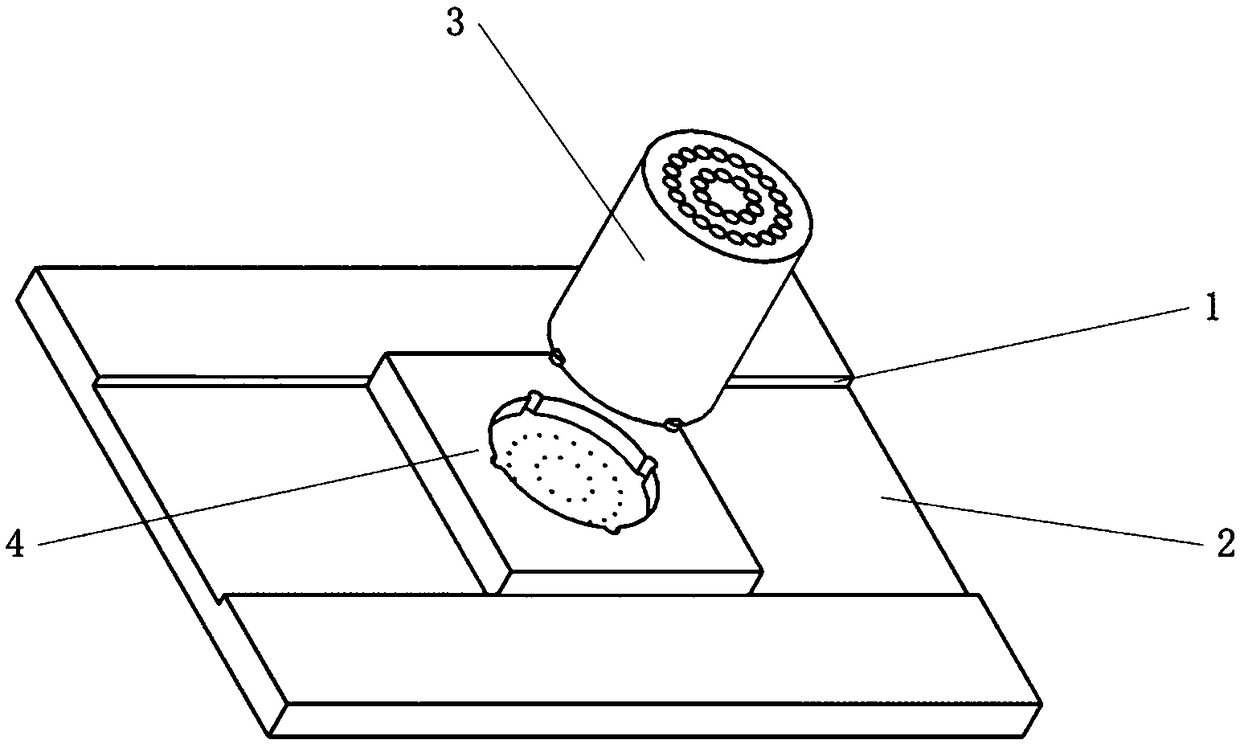

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

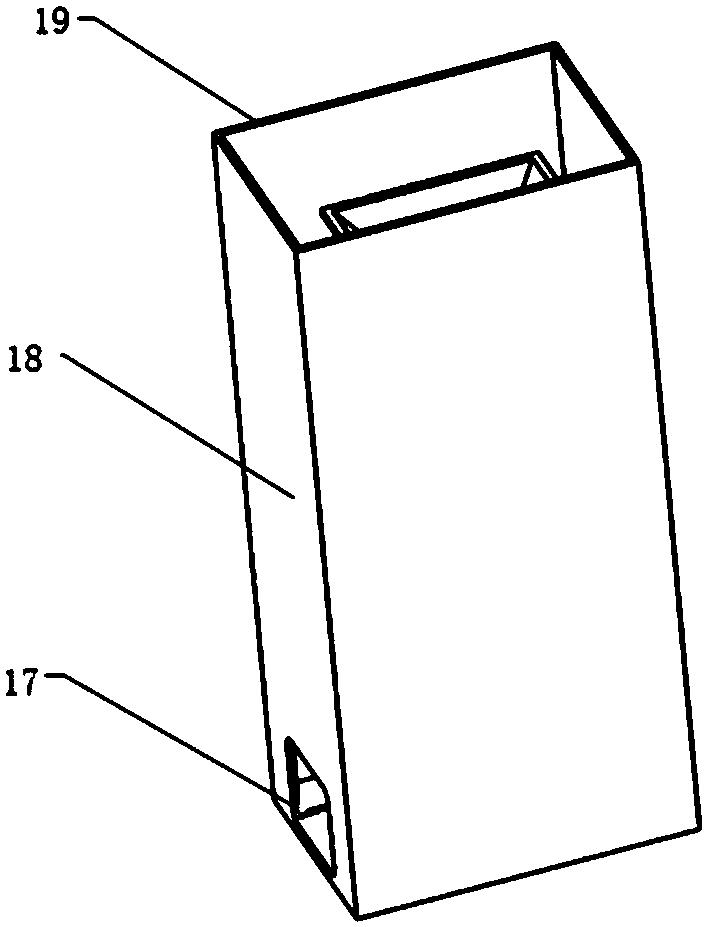

[0032] figure 1 It shows the integrated machine for shredding paper and synthesizing environmentally friendly paper pencils. The mouth-shaped funnel 7 used for the entry of paper scraps is set on the top opening of the shell 18, and the lower mouth of the mouth-shaped funnel is connected to the paper scraps storage barrel 8 and the conduit 13 in turn. And the pulp mixing bucket 5 that is inclined to be arranged, DC motor 10 is installed on the bottom of pulp mixing bucket 5, from the hole at the bottom of the bottom, the DC motor shaft that stretches into the pulp mixing bucket is equipped with stirring blades, and the DC motor shaft and A sealing device is arranged between the holes of the lower bottom; a slidable vacuum suction cup 11 is provided at the opening of the upper end of the pulp mixing drum 5, and one end of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com