Dust-free pure black processing method for polyester-cotton blend/cotton knitted shell fabrics

A processing method and technology for knitted fabrics, applied in the field of textile dyeing and finishing, can solve the problems of fabric style discount, etc., and achieve the effects of easy operation, good pilling resistance, high color fixing rate and lifting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A dust-free and pure black processing method for polyester-cotton knitted fabrics, the fabric is 27.8tex eddy current spinning cotton yarn + 110dtex / 48F polyester low elastic yarn + 27.8tex vortex spinning cotton strands twill double sweater cloth, comprising the following steps: gray cloth singeing, Smelting, dyeing, scouring and drying, final product setting.

[0053] (1) Gray cloth singeing process

[0054] Singeing cloth speed 45m / min.

[0055] (2) Cooking process

[0056] 30% sodium hydroxide 3g / L, 27.5% hydrogen peroxide 3.6g / L (only for polyester-cotton knitted fabrics), hydrogen peroxide stabilizer PL (mixture of sodium silicate and hydroxy acid salts) 1.0g / L (only for polyester Cotton knitted fabric), degreasing agent (fatty acid methyl ester ethoxylate) 1~2g / L, penetrant (fatty alcohol polyoxyethylene ether) 1g / L, scouring agent (secondary alkyl yellow acid sodium and fatty alcohol poly Oxyethylene ether mixture) 1g / L, bath ratio 1:8, pH value 8.5-9.5, temp...

Embodiment 2

[0084] A dust-free pure black processing method for cotton / spandex knitted fabric, the fabric is 22tex eddy current spinning cotton yarn (95%) + 22dtex spandex (5%) plain cloth, comprising the following steps: gray fabric singeing, presetting, scouring, dyeing , Washing and drying, finished product stereotypes.

[0085] (1) Gray cloth singeing process

[0086] Singeing cloth speed 45m / min.

[0087] (2) Pre-forming process

[0088] The temperature is 205°C, the cloth speed is 40m / min, and it is dry set.

[0089] (3) Cooking process

[0090] 30% sodium hydroxide 3g / L, 27.5% hydrogen peroxide 3.6g / L (only for polyester-cotton knitted fabrics), hydrogen peroxide stabilizer PL (mixture of sodium silicate and hydroxy acid salts) 1.0g / L (only for polyester Cotton knitted fabric), degreasing agent (fatty acid methyl ester ethoxylate) 1~2g / L, penetrant (fatty alcohol polyoxyethylene ether) 1g / L, scouring agent (secondary alkyl yellow acid sodium and fatty alcohol poly Oxyethylene ...

Embodiment 3

[0105] A dust-free and pure black processing method for cotton knitted fabric, the fabric is 27.8tex vortex spun cotton yarn plain fabric, comprising the following steps: gray fabric singeing, scouring, dyeing, scouring and drying, and final product setting.

[0106] (1) Gray cloth singeing process

[0107] Singeing cloth speed 45m / min.

[0108] (2) Cooking process

[0109] 30% sodium hydroxide 3g / L, 27.5% hydrogen peroxide 3.6g / L (only for polyester-cotton knitted fabrics), hydrogen peroxide stabilizer PL (mixture of sodium silicate and hydroxy acid salts) 1.0g / L (only for polyester Cotton knitted fabric), degreasing agent (fatty acid methyl ester ethoxylate) 1~2g / L, penetrant (fatty alcohol polyoxyethylene ether) 1g / L, scouring agent (secondary alkyl yellow acid sodium and fatty alcohol poly Oxyethylene ether mixture) 1g / L, bath ratio 1:8, pH value 8.5-9.5, temperature 98-130°C, time 30min.

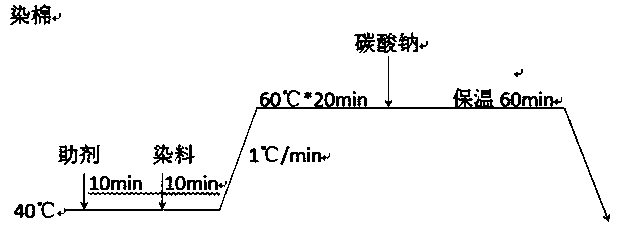

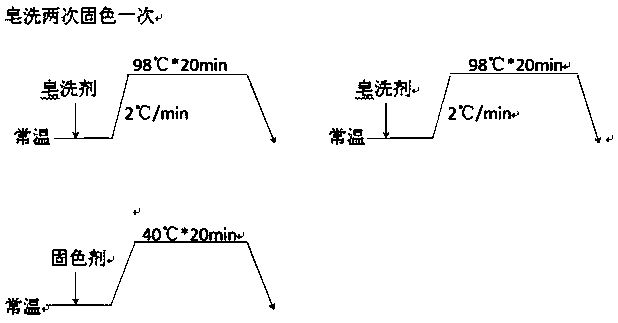

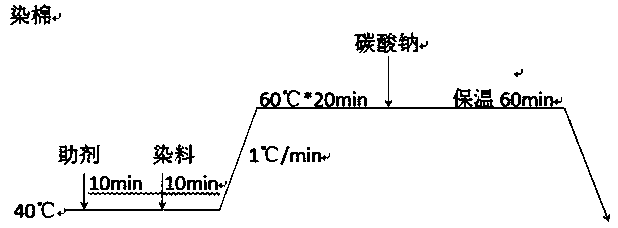

[0110] (3) Dyeing process

[0111] Super black M-type reactive dye G300% [anthr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com