Composite friction material which is based on carbon component with controllable size and dimension and preparation method of composite friction material

A technology of composite friction materials and friction materials, applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of friction coefficient, small wear rate, low friction performance, and low porosity, so as to improve friction and wear Performance, improvement of friction and wear and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

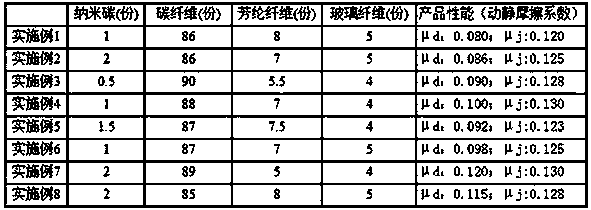

Embodiment 1

[0030] Example 1: A composite friction material based on the controllable scale and dimension of carbon components. The base material of the steel core plate layer is made of special heat-resistant carbon fiber 65Mn material, including the bottom layer, the middle layer and the upper layer. The bottom layer and the upper layer are connected through the middle layer. Bonded, the bottom layer is a steel core plate, the middle layer is an organic binder, and the upper layer is an annular carbon-based friction layer.

[0031] The preparation method of the composite friction material based on the controllable scale and dimension of carbon components, the specific process is as follows:

[0032] (1) The proportion of carbon components:

[0033] 1 part of nano-carbon, 86 parts of carbon fiber, 8 parts of aramid fiber, and 5 parts of glass fiber.

[0034] Ball milling alloying of nano-carbon and copper powder, nano-carbon and copper powder are melted rapidly at a temperature of 65°C,...

Embodiment 2

[0055] Example 2: A composite friction material based on the controllable scale and dimension of carbon components. The base material of the steel core layer is made of special heat-resistant carbon fiber 65mn material, including the bottom layer, the middle layer and the upper layer. The bottom layer and the upper layer are connected through the middle layer. Bonded, the bottom layer is a steel core plate, the middle layer is an organic binder, and the upper layer is an annular carbon-based friction layer.

[0056] The preparation method of the composite friction material based on the controllable scale and dimension of carbon components, the specific process is as follows:

[0057] (1) The proportion of carbon components:

[0058] 2 parts of nano-carbon, 86 parts of carbon fiber, 7 parts of aramid fiber, and 5 parts of glass fiber.

[0059] Ball milling alloying of nano-carbon and copper powder, nano-carbon and copper powder are melted rapidly at a temperature of 65°C, cool...

Embodiment 3

[0080] Example 3: A composite friction material based on the controllable scale and dimension of carbon components. The base material of the steel core layer is made of special heat-resistant carbon fiber 65mn material, including the bottom layer, the middle layer and the upper layer. The bottom layer and the upper layer are connected through the middle layer. Bonded, the bottom layer is a steel core plate, the middle layer is an organic binder, and the upper layer is an annular carbon-based friction layer.

[0081] The preparation method of the composite friction material based on the controllable scale and dimension of carbon components, the specific process is as follows:

[0082] (1) The proportion of carbon components:

[0083] 0.5 parts of nano-carbon, 90 parts of carbon fiber, 5.5 parts of aramid fiber, and 4 parts of glass fiber.

[0084] Ball milling alloying of nano-carbon and copper powder, nano-carbon and copper powder are melted rapidly at a temperature of 65°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quenching hardness | aaaaa | aaaaa |

| Quenching hardness | aaaaa | aaaaa |

| Quenching hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com