Fluopyram and synthesis method thereof

A technology of fluopyram and its synthesis method, which is applied in the synthesis and application fields of fine chemical products, can solve the problems of low content and yield of fluopyram, high production cost of fluopyram, and poor use effect, etc. Achieve the effect of easy operation and implementation, avoid loss and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

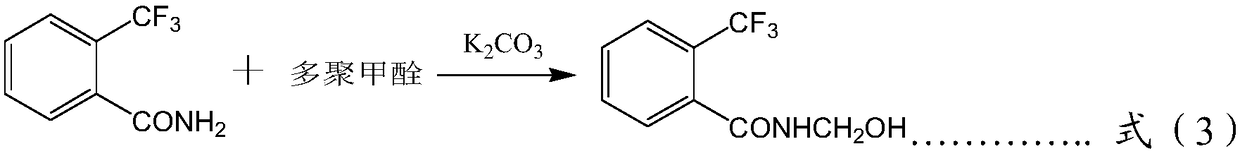

[0048] A synthetic method for fluopyram, comprising the following steps:

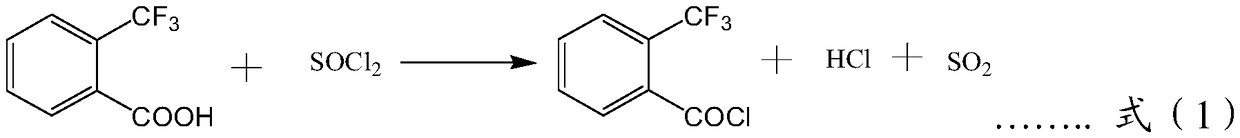

[0049] Step 1, add 96g of o-trifluoromethylbenzoic acid and 200g of thionyl chloride to a 500mL three-necked flask, start stirring at a speed of 95 rpm, heat up to 79°C and reflux for 6 hours, then in a vacuum of -0.085MPa, 55°C negative pressure recovery of thionyl chloride for 1.5 hours to obtain o-trifluoromethylbenzoyl chloride, hydrogen chloride and sulfur dioxide gas; the specific chlorination process is shown in formula (1):

[0050]

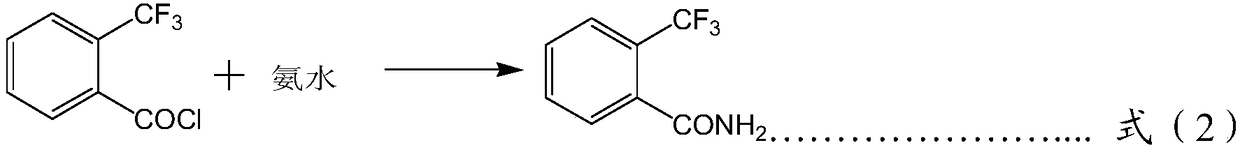

[0051] Step 2, add 360g ammoniacal liquor in the there-necked bottle of 500mL, start to stir with rotating speed as 95 revs / min, add o-trifluoromethylbenzoyl chloride dropwise while stirring in ammoniacal liquor, o-trifluoromethylbenzoyl chloride is at 20 Add dropwise in 30 minutes under the condition of ℃, continue to stir for 1 hour, then filter under the condition of vacuum degree of -0.085MPa for 10 minutes, and dry at 80 ℃ for 3 hours to obtain 90g of o-tri...

Embodiment 2

[0063] A synthetic method for fluopyram, comprising the following steps:

[0064] Step 1, add 90g of o-trifluoromethylbenzoic acid and 180g of thionyl chloride to a 500mL three-necked flask, start stirring at a speed of 95 rpm, heat up to 79°C and reflux for 5.5 hours, then in a vacuum of -0.090MPa, 45°C under negative pressure to recover thionyl chloride for 1.7 hours to obtain o-trifluoromethylbenzoyl chloride, hydrogen chloride and sulfur dioxide gas.

[0065] Step 2, add 340g ammoniacal liquor in the there-necked bottle of 500mL, start to stir with rotating speed at 95 rpm, add o-trifluoromethylbenzoyl chloride dropwise while stirring in ammoniacal liquor, o-trifluoromethylbenzoyl chloride is at 15 Add dropwise in 36 minutes under the condition of ℃, continue to stir for 1.1 hours, then filter under the condition of vacuum degree of -0.087MPa for 15 minutes, and dry at 75℃ for 3.2 hours to obtain o-trifluoromethylbenzamide white Solid, 93.2% yield from the first two steps...

Embodiment 3

[0072] A synthetic method for fluopyram, comprising the following steps:

[0073] Step 1, add 102g of o-trifluoromethylbenzoic acid and 220g of thionyl chloride to a 500mL three-necked flask, start stirring at a speed of 95 rpm, heat up to 79°C and reflux for 6.5 hours, then in a vacuum of -0.085MPa, 55°C under negative pressure to recover thionyl chloride for 1.3 hours to obtain o-trifluoromethylbenzoyl chloride, hydrogen chloride and sulfur dioxide gas.

[0074] Step 2, add 360g ammoniacal liquor in the there-necked bottle of 500mL, start to stir with rotating speed as 95 revs / min, add o-trifluoromethylbenzoyl chloride dropwise while stirring in ammoniacal liquor, o-trifluoromethylbenzoyl chloride is at 15 Add dropwise in 30 minutes under the condition of ℃, continue to stir for 1.2 hours, then filter under the condition of vacuum degree of -0.090MPa for 10 minutes, and dry at 85℃ for 2.8 hours to obtain o-trifluoromethylbenzamide white Solid, 93.1% yield from the first two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com