Scaffold steel pipe maintaining method

A scaffolding and steel pipe technology, used in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of inability to grind and apply protective oil, low maintenance efficiency of steel pipes, poor operational flexibility, etc., to improve rust removal efficiency. , Improve the quality of rust removal, improve the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

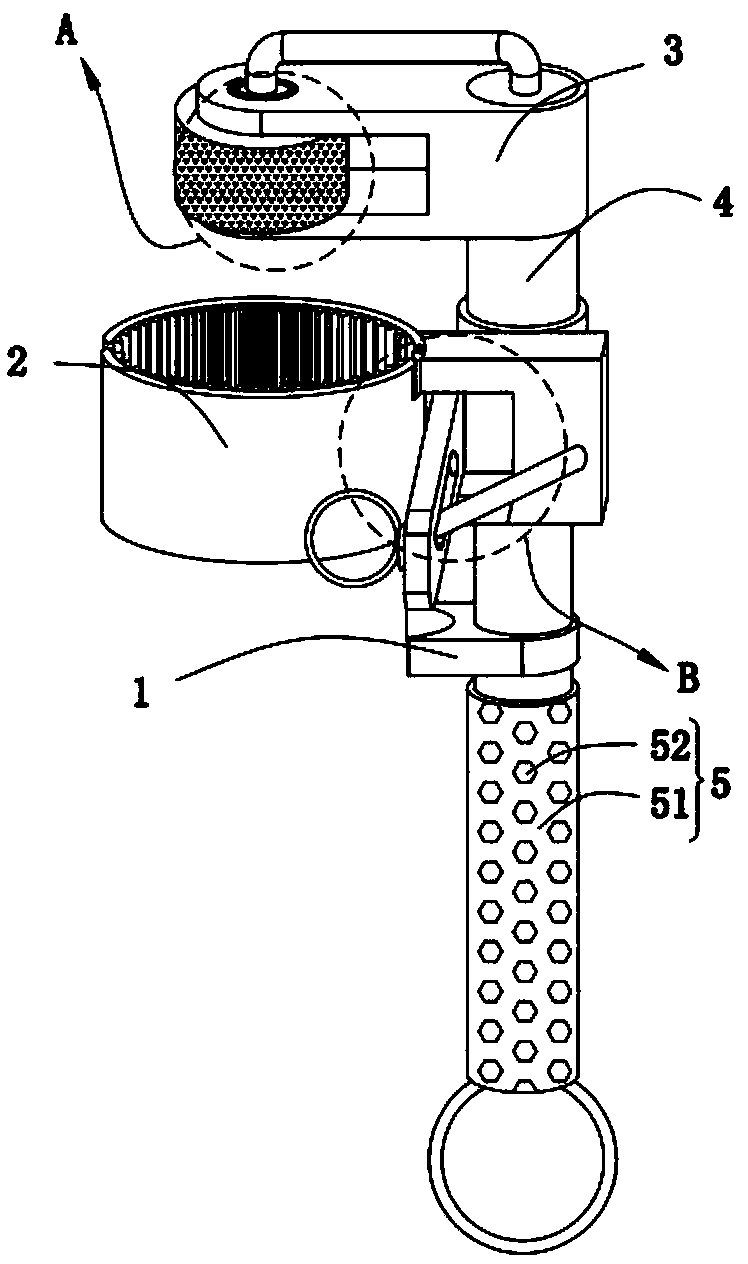

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0028] like figure 1 Shown, a kind of scaffold steel pipe maintenance method described in the present invention, this method comprises the following steps:

[0029] Step 1: Clean up the debris attached to the steel pipe;

[0030] Step 2: straightening the steel pipe in step 1;

[0031] Step 3: Send the steel pipe in Step 2 into the derusting device;

[0032] Step 4: Put the steel pipes in Step 3 into storage;

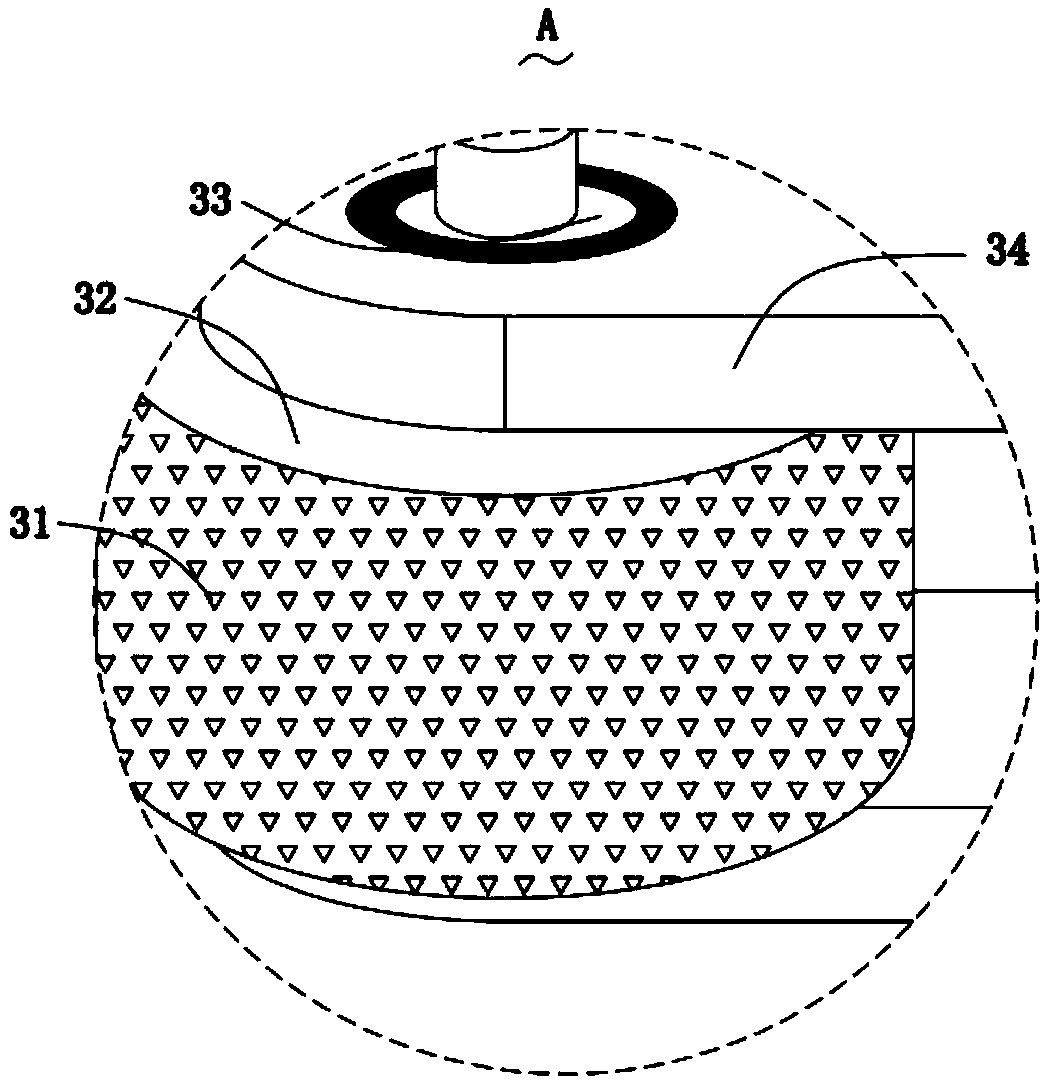

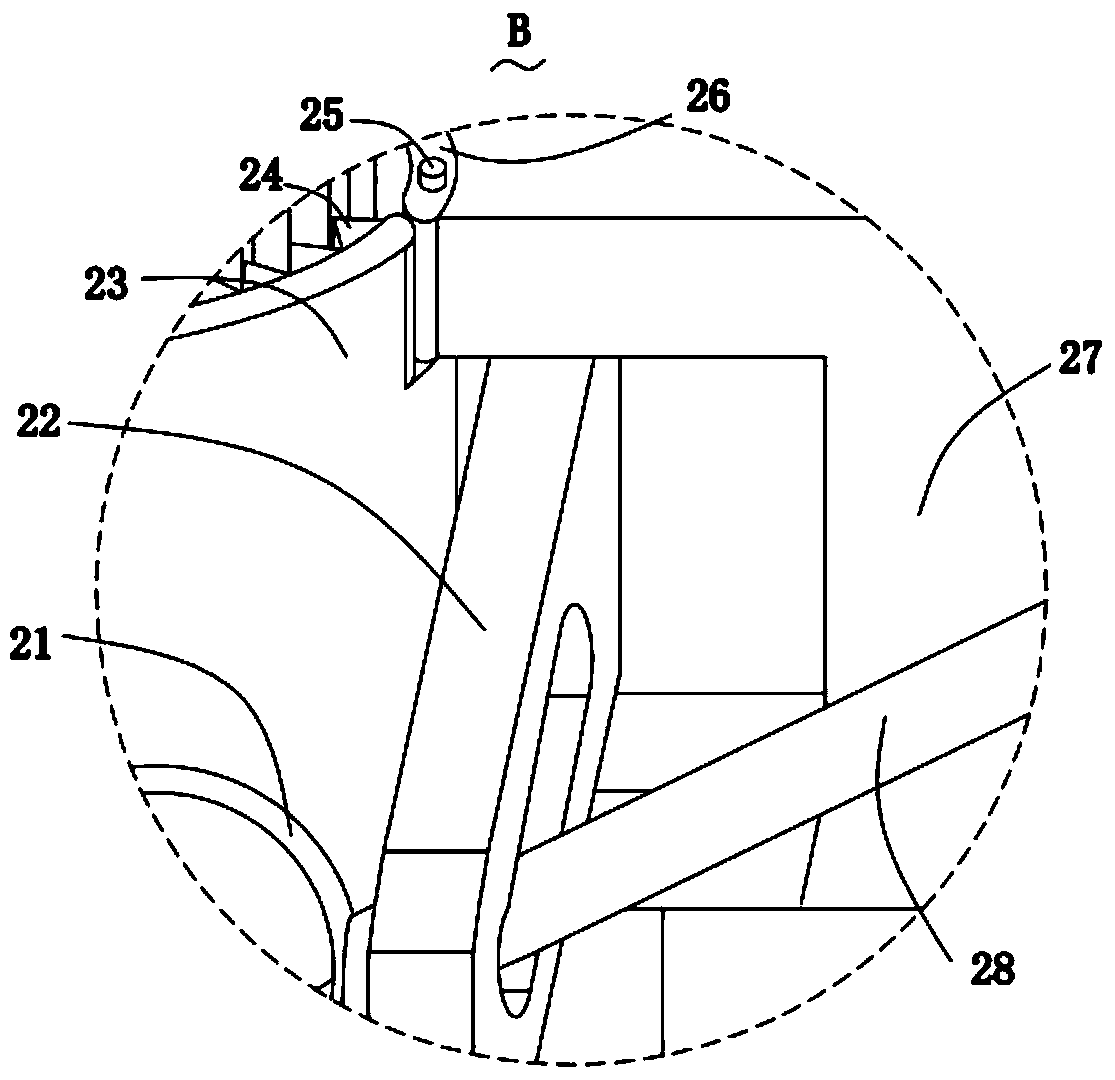

[0033] Wherein, the derusting device includes a first derusting structure 2, a second derusting structure 3, a lubricating structure 4 and an anti-skid structure 5; the anti-skid structure 5 of the cylindrical structure is provided with a device for applying anti-rust oil The lubricating structure 4 is socketed between the anti-slip str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com