Rust removal device for automobile mold

A technology for automobile molds and dust removal devices, which is applied to cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. , The effect of rust removal in a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

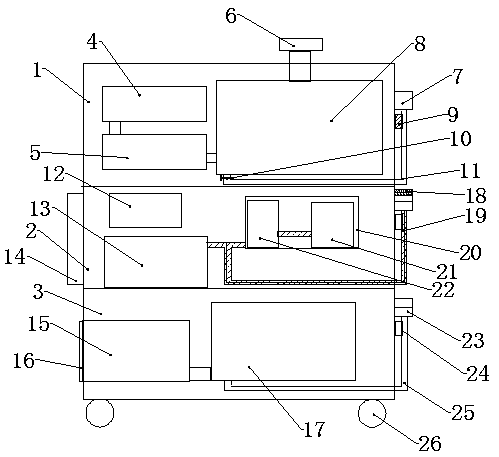

[0016] Such as Figure 1-2 Shown, a kind of rust removal device for automobile mould, it comprises rust prevention device 1, laser rust removal device 2 and dust removal device 3, the inside of described rust prevention device 1 is provided with compressor 4, and described compressor 4 A gas storage tank 5 is connected, the gas storage tank 5 is connected with an oil storage tank 8, a feed inlet 6 is arranged above the oil storage tank 8, and a spraying pipe is arranged below the oil storage tank 8 11. A solenoid valve 10 is provided on the spraying pipe 11, a nozzle 7 is connected to the tail of the spraying pipe 11, and a vibrating mirror controller 12 and a laser refrigerator 13 are arranged inside the laser descaling device 2 And rust removal laser 20, described rust removal laser 29 is made up of light source 21 and beam expander 22 electrical connections, and described laser refrigerator 13 and beam expander 22 are all connected with fiber tube 19, and described fiber tu...

Embodiment 2

[0019] Such as Figure 1-2 Shown, a kind of rust removal device for automobile mould, it comprises rust prevention device 1, laser rust removal device 2 and dust removal device 3, the inside of described rust prevention device 1 is provided with compressor 4, and described compressor 4 A gas storage tank 5 is connected, the gas storage tank 5 is connected with an oil storage tank 8, a feed inlet 6 is arranged above the oil storage tank 8, and a spraying pipe is arranged below the oil storage tank 8 11. A solenoid valve 10 is provided on the spraying pipe 11, a nozzle 7 is connected to the tail of the spraying pipe 11, and a vibrating mirror controller 12 and a laser refrigerator 13 are arranged inside the laser descaling device 2 And rust removal laser 20, described rust removal laser 29 is made up of light source 21 and beam expander 22 electrical connections, and described laser refrigerator 13 and beam expander 22 are all connected with fiber tube 19, and described fiber tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com