Cleaning machine

A cleaning machine and cleaning tank technology, which is applied in the field of cleaning machines, can solve the problems of low work efficiency, complicated devices, and high labor intensity, and achieve the effects of convenient rust removal, simple structure, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

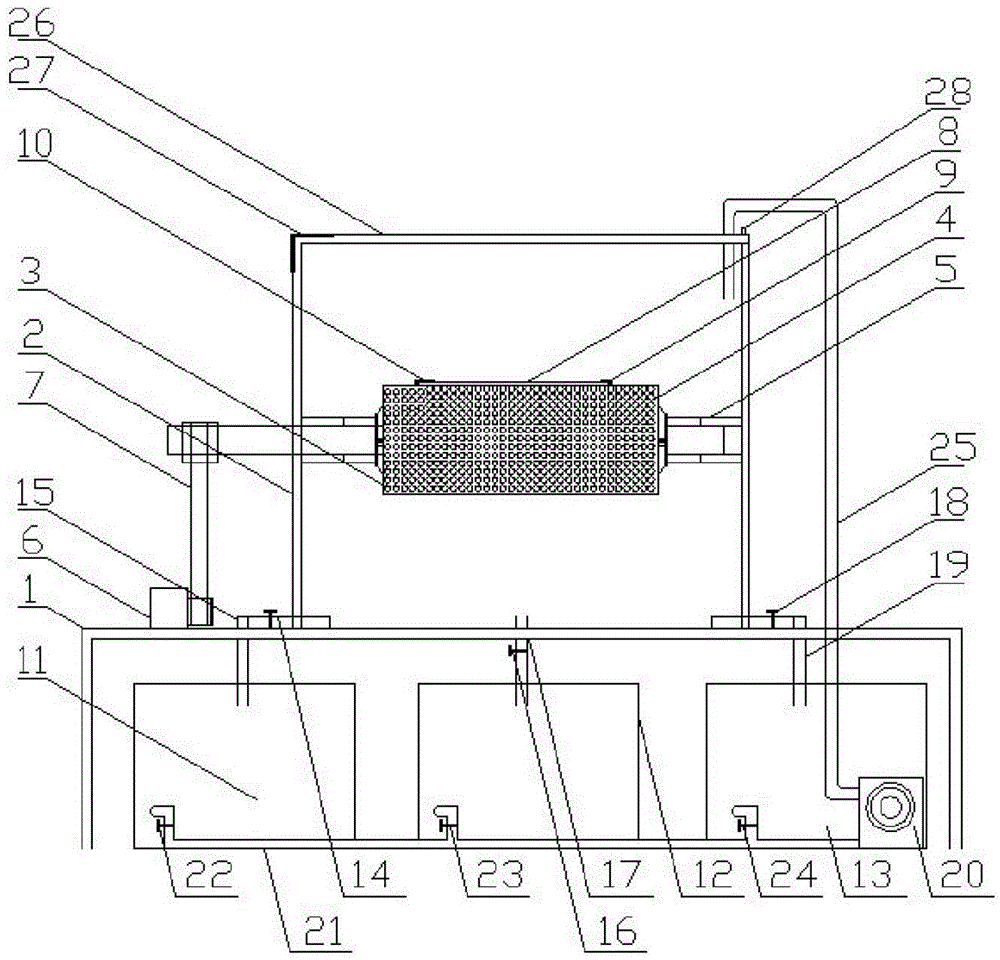

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown in the schematic diagram of the structure, the present invention includes a support frame 1 and a cleaning tank 2 placed on the support frame 1, and the derusting device also includes a drum 4 and a drive motor 6 with a through hole 3 smaller than the diameter of the nail, and an acid storage tank 11 , the lye pool 12, the pool 13, the cylinder 4 is horizontally placed in the middle of the cleaning tank 2, the two ends are fixedly connected with the rotating shaft 5, the left end shaft head of the rotating shaft 5 passes through the cleaning tank 2, and is connected with the belt 7 The external drive motor 6 is connected, and a feed inlet is provided on the roller wall of the drum 4, and a feed door 8 is installed on the feed inlet, and one side of the feed door 8 is fixed on the drum by a first hinge 9. 4, the other end of the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com