Roller coating production method for figure code insulating burglarproof door

A production method and technology for anti-theft doors, which are applied to door leaves, processes for producing decorative surface effects, decorative arts, etc., can solve the problems of inability to transfer metal plates, lack, and inability to correct errors, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a roll coating production method for a picture-code thermal insulation anti-theft door, which includes the following steps in turn: A. the step of producing inner and outer metal decorative panels; and B. adding an insulating layer to the metal decorative panels and A step of forming a pattern code insulation board between the substrates.

[0043] When producing metal veneer in described step A, comprise the following steps successively:

[0044] a. The steps of producing metal plates, specifically: hot-rolling steel coils, pickling the hot-rolled steel coils with hydrochloric acid, cold-rolling the pickled steel coils, and cold-rolling the cold-rolled steel coils The steel coil is subjected to continuous hot-dip galvanizing treatment at 650°C (you can also select other temperature values between 650°C-850°C to form a metal plate. Here, continuous hot-dip galvanizing treatment at 650°C is equivalent to first After the annealing treatment, the...

Embodiment 2

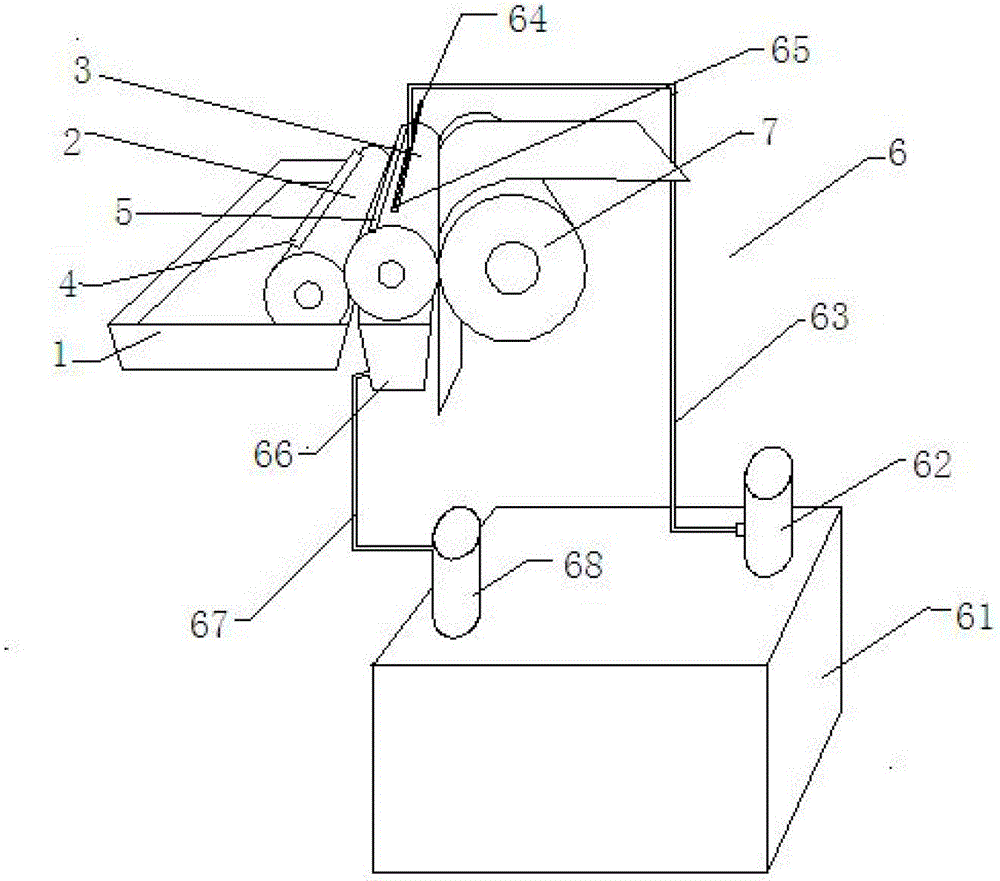

[0061] In this embodiment, a structure of the roller coating transfer printing unit used in step c and step d in embodiment 1 is provided. For the specific structure, see figure 1 , the roller coating unit includes feeding equipment 1 for providing coating; suction roller 2, whose peripheral surface is connected with the feeding equipment 1, and has an image area formed when filling with the coating on the peripheral surface a plurality of depressions; the rubber coating roller 3, whose peripheral surface is connected with the suction roller 2, is used to accept the image area formed by the coating on the coating roller 3, and transfer the image area onto the steel plate; also includes a first scraper 4, installed on the first scraper bracket, contacting the suction roller 2 at a specific angle, for scraping off the paint outside the image area of the suction roller 2 The second scraper 5, installed on the second scraper bracket, is in contact with the coating roller 2 at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com