Preparation method and application of octahedral nitrogen doped carbon framework material

A framework material and octahedral technology, applied in the field of composite carbon materials, can solve the problems of easy agglomeration, small specific surface area, limited catalytic ability, etc., and achieve the effects of strong anti-poisoning ability, good stability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

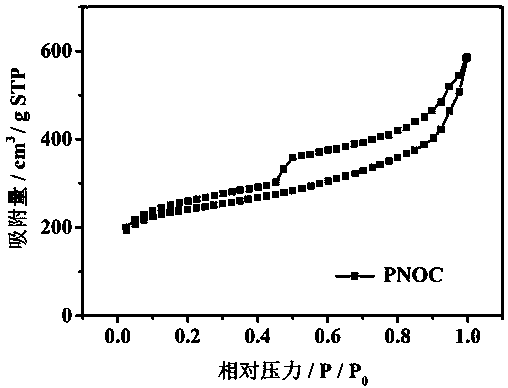

[0032] Take 0.415 g of terephthalic acid and 1.35 g of ferric chloride hexahydrate, dissolve in 30 mL of DMF, treat at 110 °C for 24 hours, wash with DMF and ethanol in turn, and obtain a relatively pure precursor substance (MIL-101(Fe )).

[0033] Add 20 mL methanol to a 100 mL flask, then add 0.4 g precursor, 0.5 g urea, and ultrasonically disperse for half an hour; after standing still, filter with suction, dry the product in an oven and put it in a tube furnace, blow nitrogen, 800 heat treatment at ℃ for 2 hours, take it out, grind it, then add it to a sulfuric acid solution with a concentration of 0.5 M, treat it at 60 ℃ for 12 hours, filter it with suction, wash it with water, and dry it to obtain an octahedral nitrogen-doped carbon framework material catalyst.

[0034] Compared with the commercial platinum-carbon catalyst, the octahedral nitrogen-doped carbon framework material catalyst has a half-potential difference of 30 mV; at -0.2V, the ratio of the initial current...

Embodiment 2

[0036] Take 0.415 g of terephthalic acid and 1.35 g of ferric chloride hexahydrate, dissolve in 30 mL of DMF, treat at 110 °C for 24 hours, wash with DMF and ethanol in turn, and obtain a relatively pure precursor substance (MIL-101(Fe )).

[0037] Add 20 mL of ethanol to a 100 mL flask, then add 0.4 g of the above precursors, 0.1 g of melamine, and ultrasonically disperse for 2 hours; after standing still, filter with suction, dry the product in an oven, put it in a tube furnace, and pass it into Nitrogen, heat treatment at 650 °C for 1 hour, take it out, and grind it; then add it to a 0.5 M hydrochloric acid solution, treat it at 60 °C for 16 hours, filter with suction, wash with water, and dry to obtain an octahedral nitrogen-doped carbon framework material catalyst.

[0038] Compared with the commercial platinum-carbon catalyst, the octahedral nitrogen-doped carbon framework material catalyst has a half-potential increase of 5 mV; at -0.2V, the ratio of the initial current...

Embodiment 3

[0040] Take 0.415 g of terephthalic acid and 1.35 g of ferric chloride hexahydrate, dissolve in 30 mL of DMF, treat at 110 °C for 24 hours, wash with DMF and ethanol in turn, and obtain a relatively pure precursor substance (MIL-101(Fe )).

[0041] Add 20 mL of acetone to a 100 mL flask, then add 0.4 g of the above precursors and 0.3 g of ammonium phosphate, ultrasonicate for 4 hours, let stand, and filter with suction. Nitrogen, heat treatment at 950°C for 4 hours, take it out, grind it, then add it to a 2M nitric acid solution, treat it at 80°C for 16 hours, filter it with suction, wash it with water, and dry it to obtain an octahedral nitrogen-doped carbon framework material catalyst .

[0042] Compared with the commercial platinum-carbon catalyst, the octahedral nitrogen-doped carbon framework material catalyst has a half-potential difference of 20 mV; at -0.2V, the ratio of the initial current to the current after 30000 s is 10 percentage points higher than that of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com