NEGATIVE ELECTRODE FOR LITHIUM METAL BATTERY, METHOD OF PREPARING NEGATIVE ELECTRODE, LITHIUM METAL BATTERY INCLUDING THE SAME, AND composite electrolyte

一种锂金属电极、锂金属电池的技术,应用在锂蓄电池、电池电极、非水电解质等方向,能够解决降低寿命和稳定性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

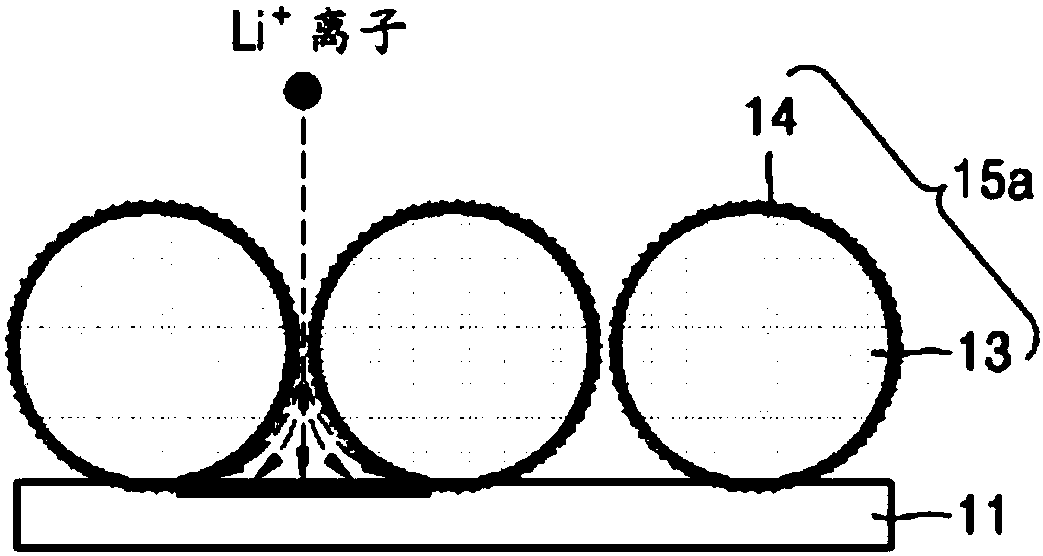

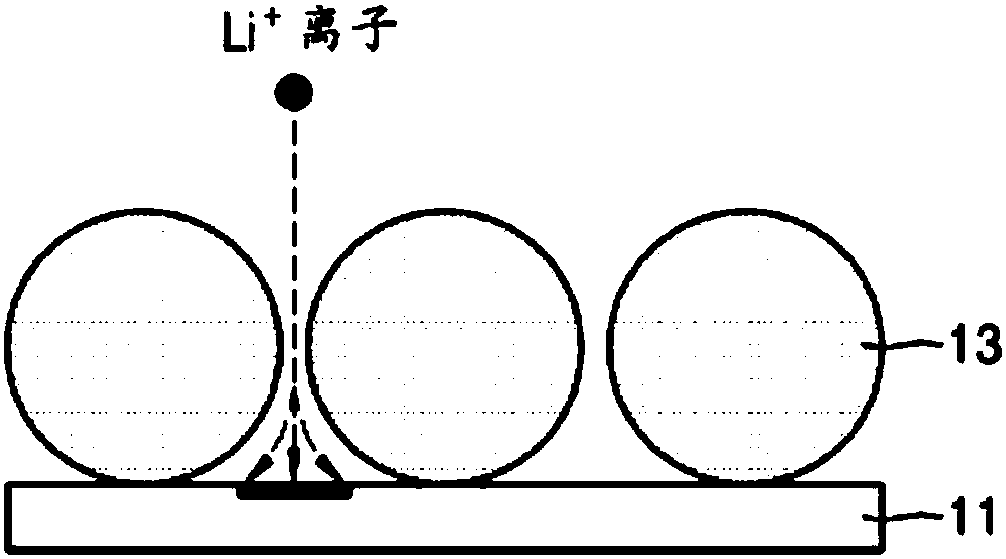

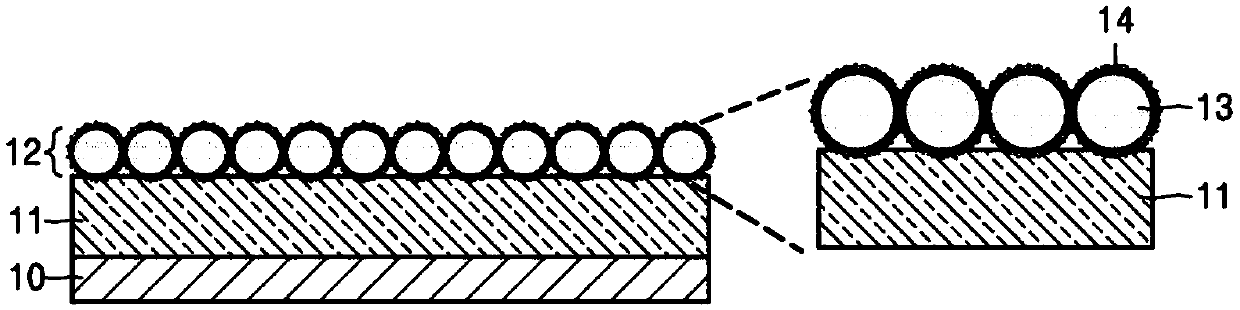

[0348] Preparation Example 1: Preparation of Composite Particles

[0349] 10 parts by weight of polyethylene glycol (PEG 200, weight average molecular weight: 200) was added to ethanol based on 100 parts by weight of ethanol. Next, poly(styrene-block-divinylbenzene) block copolymer microspheres (average particle diameter: about 3 μm, available from EPRUI Nanoparticles & Mcirospheres Co. Ltd.) were added to the mixture, and then mixed together to thereby A composite particle composition is obtained.

[0350] In the poly(styrene-block-divinylbenzene) block copolymer, the mixing weight ratio of the polystyrene block to the polydivinylbenzene block is about 98:2. The poly(styrene-block-divinylbenzene) block copolymer has a weight average molecular weight of about 100,000 Daltons.

[0351] The solvent was removed from the composite particle composition using a rotary evaporator to thereby prepare composite particles having a coating layer containing PEG200 formed on poly(styrene-...

preparation Embodiment 2

[0352] Preparation Example 2: Preparation of Composite Particles

[0353] Composite particles were prepared in substantially the same manner as in Preparation Example 1, except as follows: polyethylene glycol (PEG 600, weight average molecular weight: 600 Daltons) was used instead of polyethylene glycol (PEG 600, weight average molecular weight: 600 Daltons) when preparing the composite particle composition. Diol (PEG 200, weight average molecular weight: 200 Daltons). In the composite particles, the thickness of the coating layer containing PEG 600 is about 200 nm, and the amount of PEG 600 is about 20 parts by weight, based on 100 parts by weight of poly(styrene-block-divinylbenzene) micro ball.

preparation Embodiment 3

[0354] Preparation Example 3: Preparation of Composite Particles

[0355] Composite particles were prepared in substantially the same manner as in Preparation Example 1, except as follows: the thickness of the coating layer in the composite particles was adjusted to about 50 nm, and the amount of PEG 200 was adjusted to about 3 parts by weight, based on 100 parts by weight of poly(styrene-block-divinylbenzene) microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com