High breathable polymer coated diaphragm as well as preparation method and application thereof

A polymer and gas-permeable technology, which is applied in the field of highly gas-permeable polymer-coated diaphragm and its preparation, can solve the problems of occupying the internal space of the battery, increasing the weight and thickness of the diaphragm, and unfavorable energy density of lithium-ion batteries. Improvement of cycle performance and rate performance, improvement of performance, effect of small increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

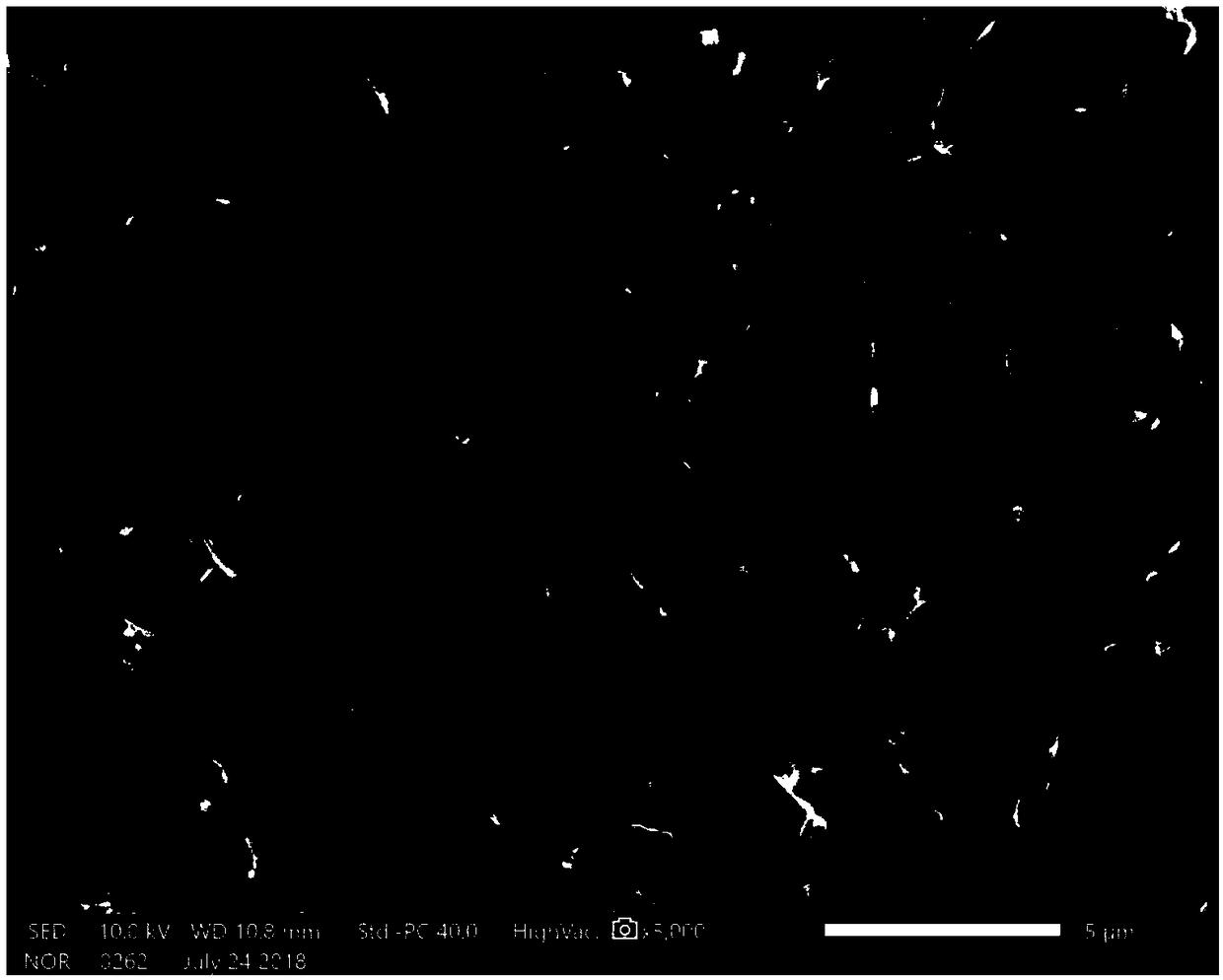

Image

Examples

Embodiment 1

[0045] Add fatty alcohol polyoxyethylene ether to deionized water to prepare a wetting solution with a mass fraction of fatty alcohol polyoxyethylene ether of 3%.

[0046] Soak one side of the polyethylene porous membrane in the wetting solution for 3 minutes to obtain a wet polyethylene porous membrane.

[0047] Mix polyvinylidene fluoride, cellulose, polyvinylpyrrolidone, and nitrogen methyl formamide at a ratio of 1:1:0.54:7.7, stir at 60°C for 8 hours, and let stand for 12 hours to remove air bubbles to obtain a casting solution.

[0048] The casting liquid is coated on the wetted polyethylene porous membrane to obtain a wet membrane. The coating thickness of the wet film was 1 micron.

[0049] Soak the wet film in an aqueous solution with a mass fraction concentration of fatty acid polyoxyethylene ether of 8%, to obtain a primary film.

[0050] Soak the as-formed film in deionized water for 3 days, and dry it at 60°C to obtain a highly gas-permeable polymer-coated separ...

Embodiment 2

[0054] Add fluoroalkyl methoxy ether alcohol to deionized water to prepare a wetting solution with a mass fraction of fluoroalkyl methoxy ether alcohol of 5%.

[0055] Soak one side of the polypropylene porous membrane in the wetting solution for 10 seconds to obtain a wet polypropylene porous membrane.

[0056] Mix polyacrylonitrile, lithium chloride, triethyl phosphate and dimethyl sulfoxide at a ratio of 1:0.025:2:2.75, stir at 50°C for 18 hours, and let stand for 12 hours to remove air bubbles to obtain a casting solution.

[0057] The casting solution was coated on the wet polypropylene porous membrane to obtain a wet membrane. The coating thickness of the wet film was 50 microns.

[0058] Soak the wet film in an aqueous solution with a mass fraction of 5% fluoroalkyl methoxy ether alcohol to obtain a primary film.

[0059] Soak the as-formed film in deionized water for 7 days, and dry it at 50°C to obtain a highly air-permeable polymer-coated separator.

[0060] The d...

Embodiment 3

[0063] Alkylphenol polyoxyethylene ether was added to deionized water to prepare a wetting solution with a mass fraction of alkylphenol polyoxyethylene ether of 1%.

[0064] Soak one side of the polyimide porous membrane in the wetting solution for 5 minutes to obtain a wet polyimide porous membrane.

[0065] Mix polymethylmethacrylate, polyvinylpyrrolidone, polyethylene glycol and dimethylacetamide at a ratio of 1:0.082:0.091:8.95, stir at 80°C for 3 hours, and let it stand for 12 hours to remove air bubbles to obtain a casting Membrane fluid.

[0066] Coating the casting solution on the wet polyimide porous membrane to obtain a wet membrane. The coating thickness of the wet film was 10 microns.

[0067] Soak the wet film in an aqueous solution with a mass fraction of fluoroalkyl ethoxy ether alcohol of 0.1% to obtain a primary film.

[0068] Soak the as-formed film in deionized water for 5 days, and dry it at 80°C to obtain a highly air-permeable polymer-coated separator....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

| Membrane rupture temperature | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com