Heat treatment process of an amorphous soft magnetic material

A soft magnetic material, amorphous technology, applied in the field of amorphous soft magnetic material and its heat treatment process, can solve the problem of not meeting production requirements, and achieve the effects of excellent soft magnetic performance, low high frequency loss, and high magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

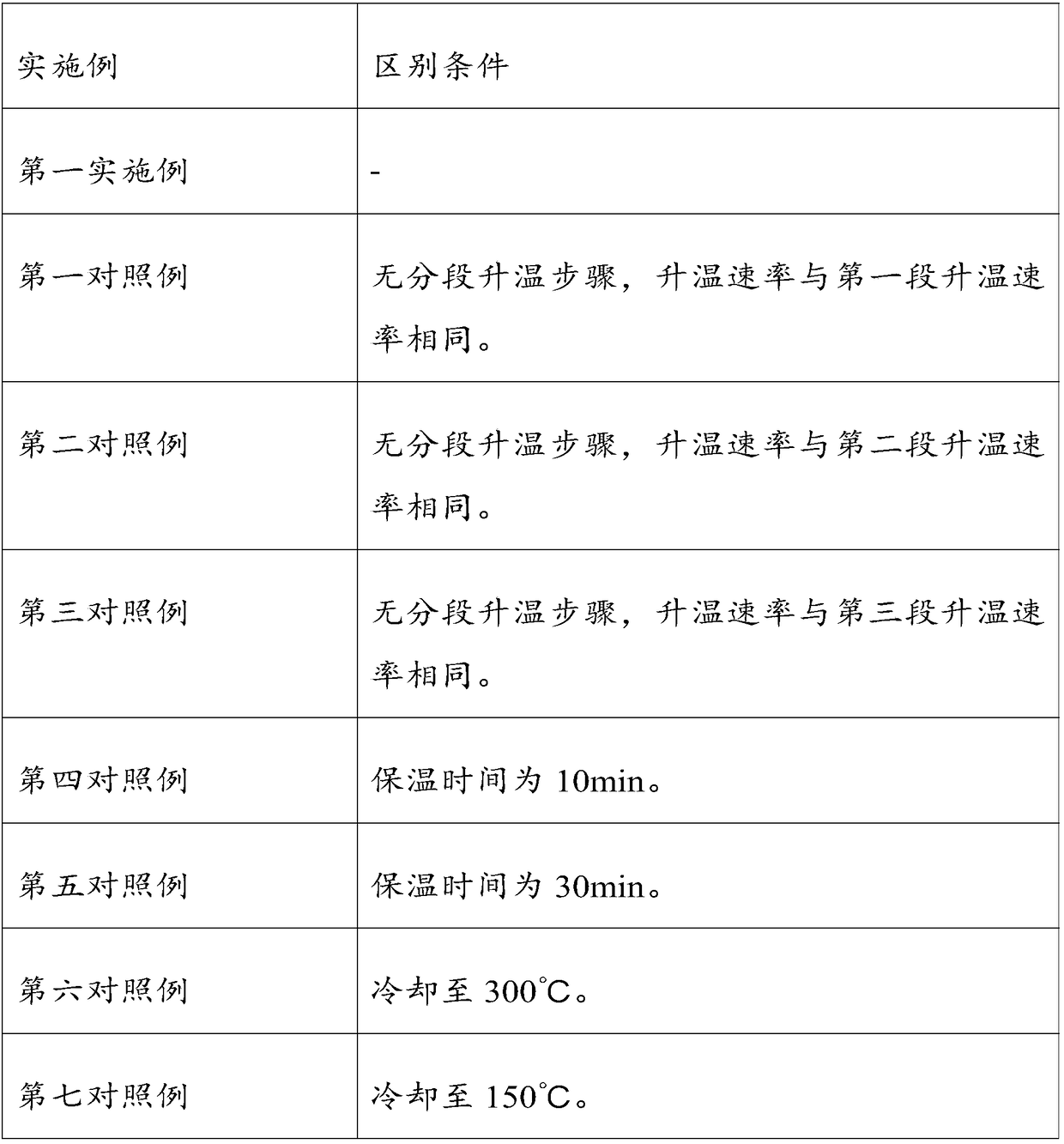

no. 1 example

[0053] This embodiment provides a heat treatment process for amorphous soft magnetic materials, which includes three steps of staged heating, heat preservation and staged cooling in a magnetic field furnace equipped with amorphous soft magnetic materials.

[0054] First, the staged cooling step:

[0055] The first stage of heating: the first stage is to raise the temperature from room temperature (25°C) to 200°C, and the heating time is 40 minutes; the second stage is to raise the temperature from 200°C to the first annealing temperature of 450°C, and the annealing time is 80 minutes;

[0056] The second stage of heating: from the first annealing temperature of 450°C to 470°C, the annealing time is 60min;

[0057] The third heating stage: from the second annealing temperature of 470°C to the third annealing temperature of 540°C, and the annealing time is 50 minutes.

[0058] Then, carry out the insulation step:

[0059] The amorphous soft magnetic material after heating up i...

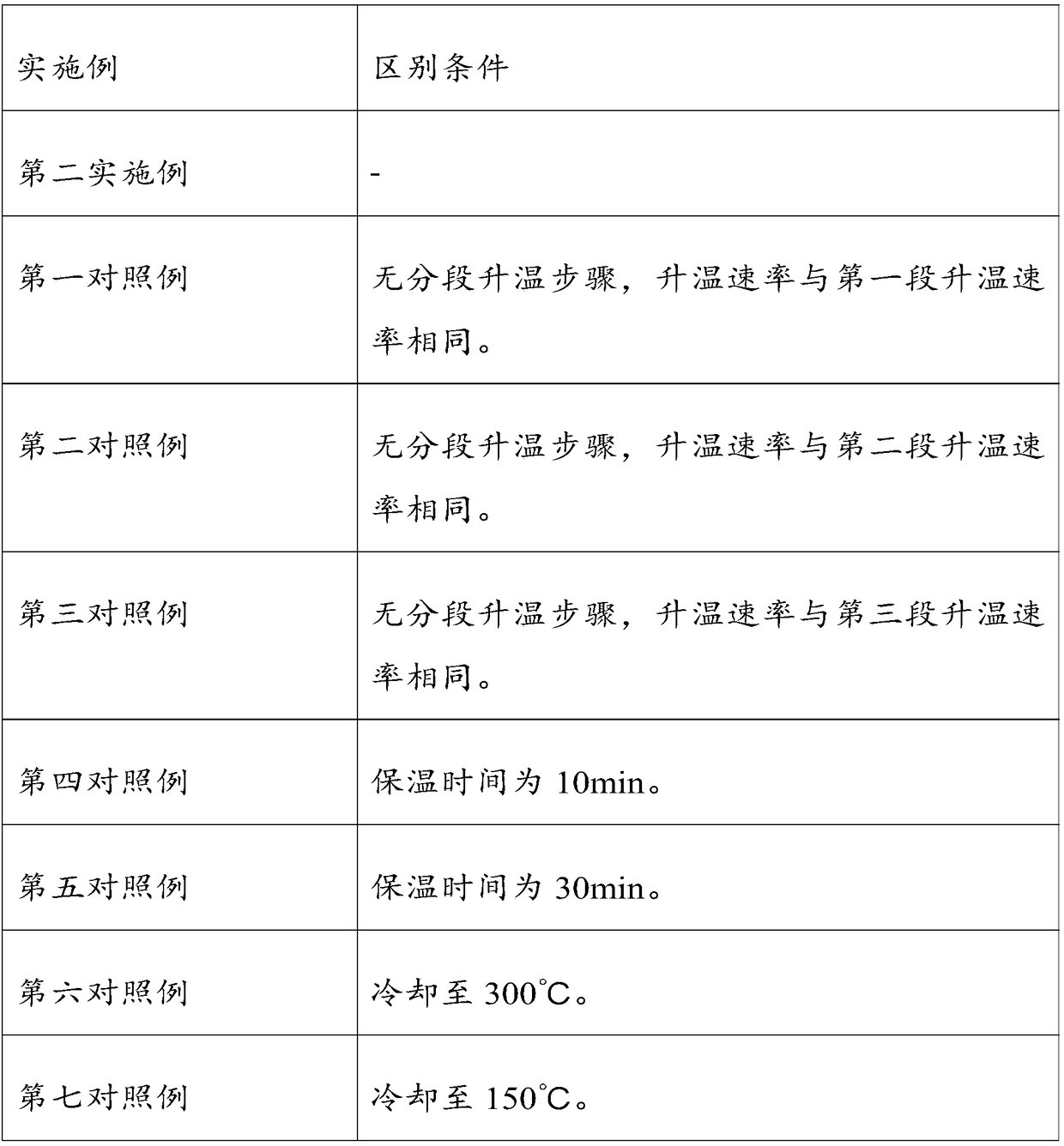

no. 2 example

[0066] This embodiment provides a heat treatment process for an amorphous soft magnetic material, which is substantially the same as the heat treatment process provided in the first embodiment, except that the parameters are different, and the differences are as follows:

[0067] First, the staged cooling step:

[0068] The first stage of heating: the first stage is to raise the temperature from room temperature (20°C) to 190°C, and the heating time is 35 minutes; the second stage is to raise the temperature from 190°C to the first annealing temperature of 445°C, and the annealing time is 75 minutes;

[0069] The second stage of heating: from the first annealing temperature of 445°C to 465°C, the annealing time is 55min;

[0070] The third heating stage: from the second annealing temperature of 465°C to the third annealing temperature of 535°C, the annealing time is 45min.

[0071] Then, carry out the insulation step:

[0072] The amorphous soft magnetic material after heati...

no. 3 example

[0079] This embodiment provides a heat treatment process for an amorphous soft magnetic material, which is roughly the same as the heat treatment process provided in the first to second embodiments, the difference lies in the different parameters, and the differences are as follows:

[0080] First, the staged cooling step:

[0081] The first stage of heating: the first stage is to raise the temperature from room temperature (23°C) to 205°C, and the heating time is 45 minutes; the second stage is to raise the temperature from 205°C to the first annealing temperature of 455°C, and the annealing time is 85 minutes;

[0082] The second stage of temperature rise: from the first annealing temperature of 455°C to 475°C, the annealing time is 65min;

[0083] The third heating stage: from the second annealing temperature of 475°C to the third annealing temperature of 545°C, and the annealing time is 55 minutes.

[0084] Then, carry out the insulation step:

[0085] The amorphous soft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com