A monitoring system and method for monitoring equipment faults

A technology for equipment failure and monitoring systems, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as low efficiency, complex environment, and increased difficulty of inspection, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

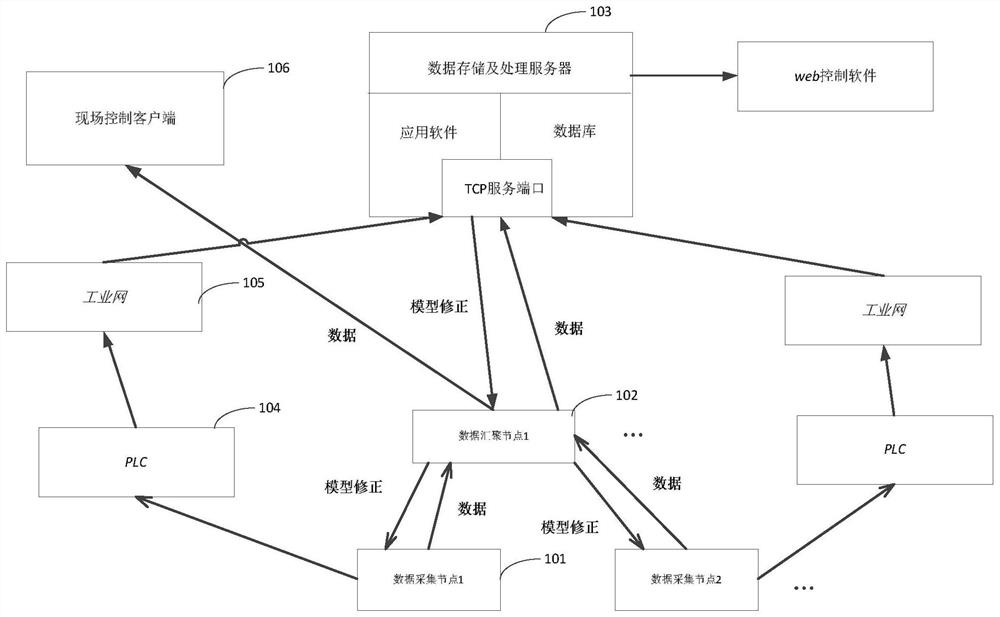

[0021] figure 1 It is a frame diagram of an equipment fault monitoring system provided by Embodiment 1 of the present invention. This embodiment is applicable to the detection of the health status of industrial equipment. Understandably, figure 1 The frame diagram of the monitoring system for equipment failure shown is only an example of the monitoring system, and the monitoring system may have more or fewer devices than shown in the figure, and two or more devices may be combined, Or it may have a different device configuration.

[0022] Such as figure 1 As shown, the monitoring system includes: a data acquisition node 101 , a data convergence node 102 , a data storage and processing server 103 , a programmable logic controller PLC 104 , an industrial network 105 and a field control client 106 .

[0023] The data acquisition node 101 is used to collect equipment state information of industrial equipment, predict the failure probability and time of failure of each industria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com