Detection system and method for zip fastener defects

A detection method and zipper technology, which are applied in the direction of optical testing for flaws/defects, measuring devices, and material analysis through optical means, can solve the problems that the detection system cannot fully and accurately detect sprocket defects, and improve production inspection efficiency. The effect of reducing the production cost of enterprises and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

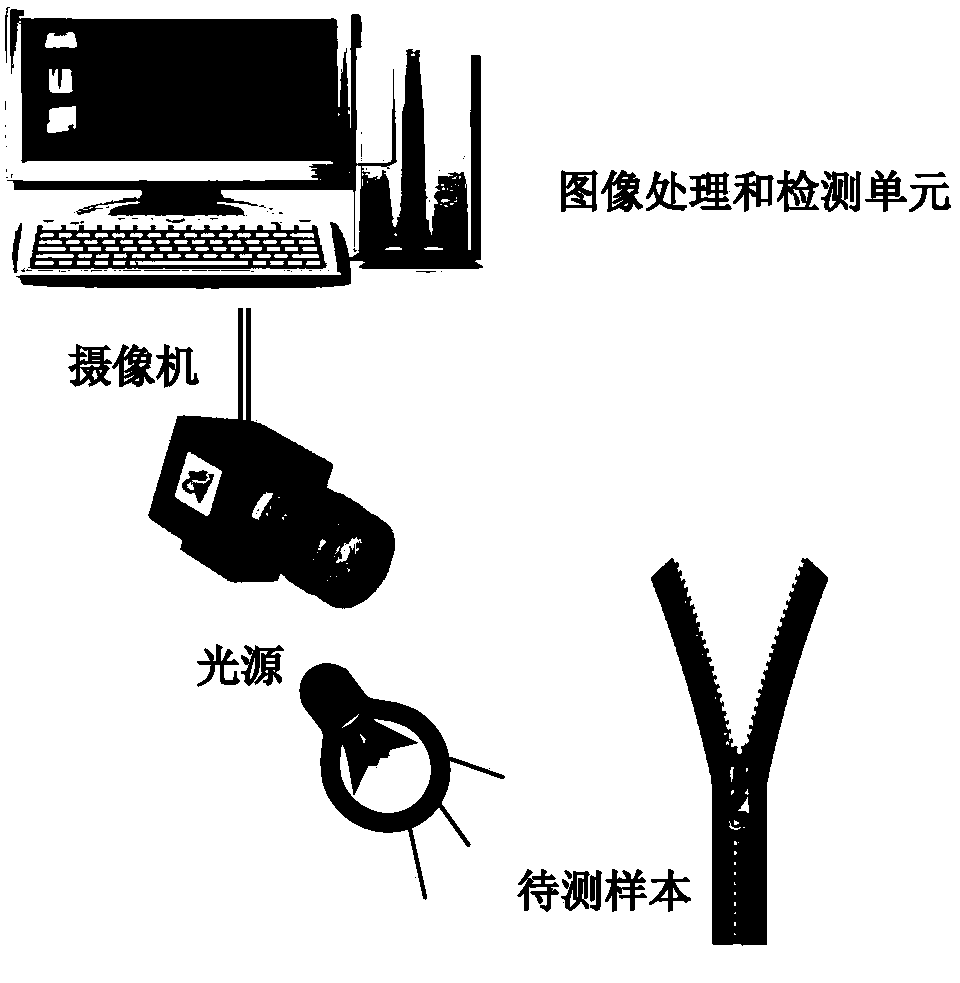

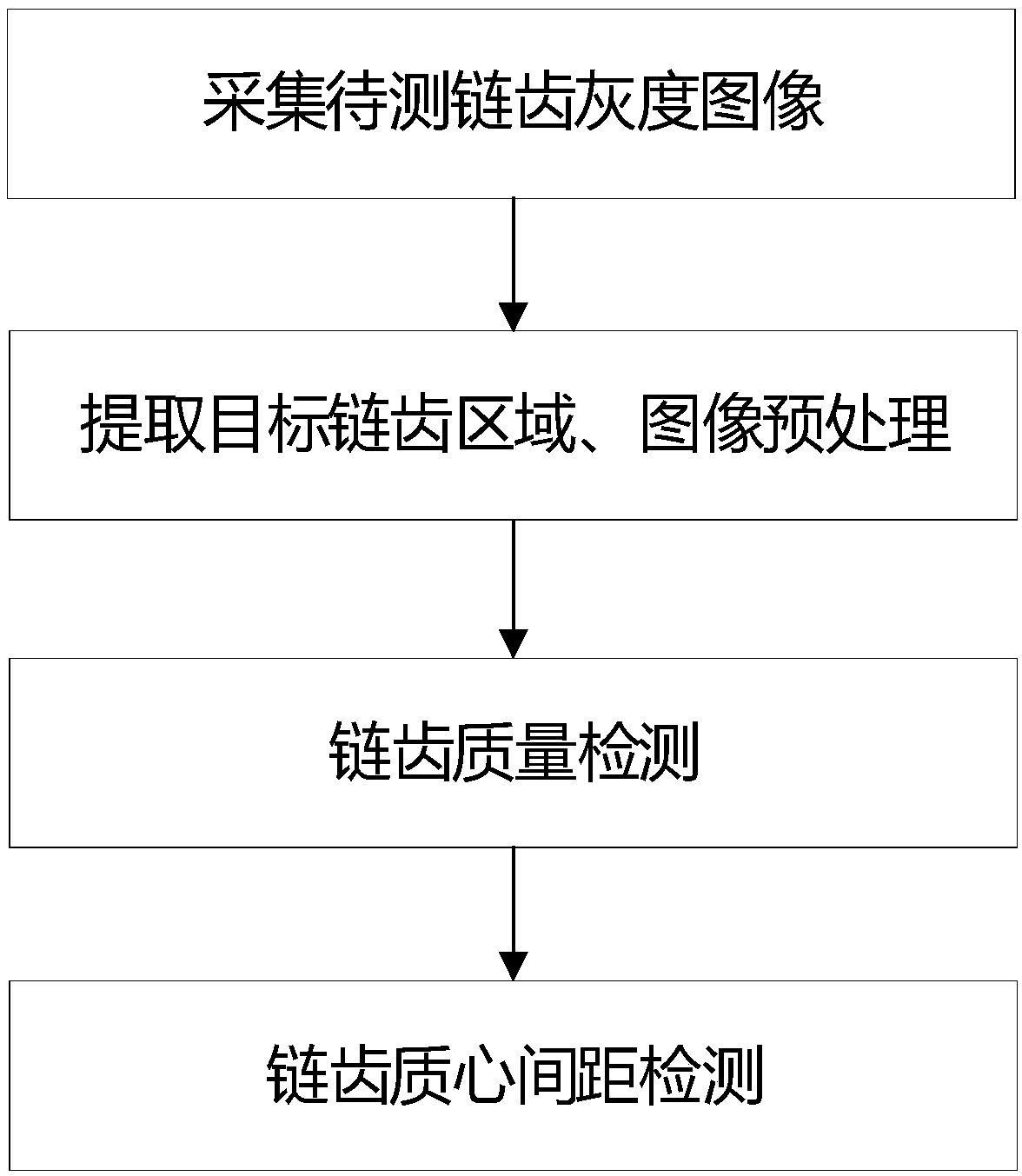

[0033] A detection system for zipper defects of the present invention, such as figure 1 As shown, including the image acquisition unit, the output end of the image acquisition unit is connected to the input end of the image processing and detection unit, the image acquisition unit includes the HDTU-JX01 fixed machine vision experimental platform, and the HDTU-JX01 fixed machine vision experimental platform is installed in the zipper The end of the production line also includes an area array industrial CCD camera. The area array industrial CCD camera is installed at the end of the zipper production line and is located on one side of the HDTU-JX01 fixed machine vision experimental platform. The image processing and inspection unit includes an industrial control computer. The industrial control computer passes The USB3.0 interface is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com