Metasurface circularly-polarized light detection component and production method thereof

A technology of circularly polarized light and detection element, which is applied in the field of metasurface circularly polarized light detection element and its preparation, can solve the problems of incompatibility, difficulty in manufacturing, and low degree of structural differentiation, and achieves strong circular polarization dichroism, large The effect of application value and low time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

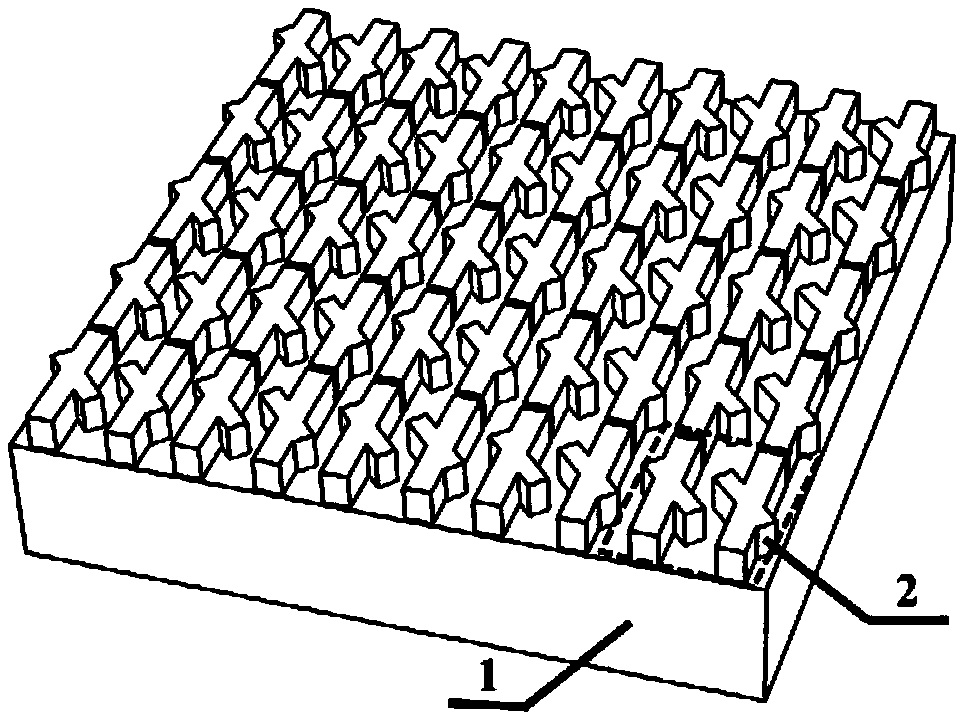

[0031] See figure 1 As shown, the metasurface circularly polarized light detection element of the present invention is composed of a light-transmitting substrate 1 and an array of rotationally symmetric chiral medium structural units 2 arranged on the light-transmitting substrate, and the rotationally symmetric chiral structures have mutual void.

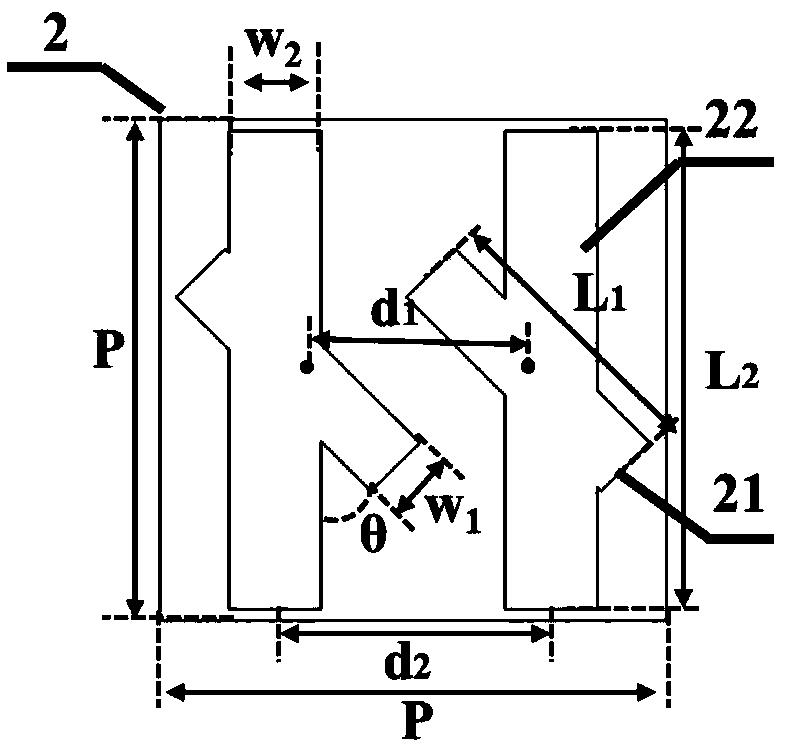

[0032] The rotationally symmetrical chiral structural unit such as figure 2 As shown, the period P of the structural unit of the rotationally symmetrical chiral medium is 1.05 μm, the thickness H of the structural unit of the rotationally symmetrical chiral medium is 0.27 μm, the length L1 of the first arm 21 is 0.6 μm, and the length L2 of the second arm 22 is 1.05 μm. μm, the width W1 of the first arm 21 is 0.15 μm, the width W2 of the second arm 22 is 0.2 μm, the horizontal distance d1 between the center points of the two first arms 21 is 0.25 μm, and the distance between the two second arms 22 The center distance d2 is 0.3 μm...

Embodiment 2

[0042] The structural parameters of the rotationally symmetrical chiral medium are: the thickness H of the medium structure layer is 0.26 μm; the period P of the rotationally symmetrical chiral medium structure is 1.0 μm, the arm length L1 is 0.5 μm, the arm length L2 is 1.0 μm, and the center of the two arms L1 The horizontal distance d1 between the points is 0.21 μm, the distance d2 between the two arms L2 is 0.24 μm, the arm width W1 is 0.12 μm, the arm width W2 is 0.17 μm, and the angle θ between the two arms 21 and 22 is 40 °.

Embodiment 3

[0044] The structural parameters of the rotationally symmetric chiral medium are: the thickness H of the medium structure layer is 0.29 μm; the period P of the rotationally symmetrical chiral medium structure is 1.2 μm, the arm length L1 is 0.8 μm, the arm length L2 is 1.07 μm, and the center of the two arms L1 The horizontal distance d1 between the points is 0.27 μm, the distance d2 between the two arms L2 is 0.33 μm, the arm width W1 is 0.21 μm, the arm width W2 is 0.26 μm, and the angle θ between the two arms 21 and 22 is 55 °.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com