A U-shaped structure for realizing circular dichroism and its preparation method

A circular dichroism and U-shaped technology is applied in the field of realizing the U-shaped structure of circular dichroism and its preparation, which can solve the problems of long preparation period, high investment cost, no simple preparation steps of three-dimensional chiral nanostructures, and the like, To achieve the effect of simple structure, reduced preparation cost and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

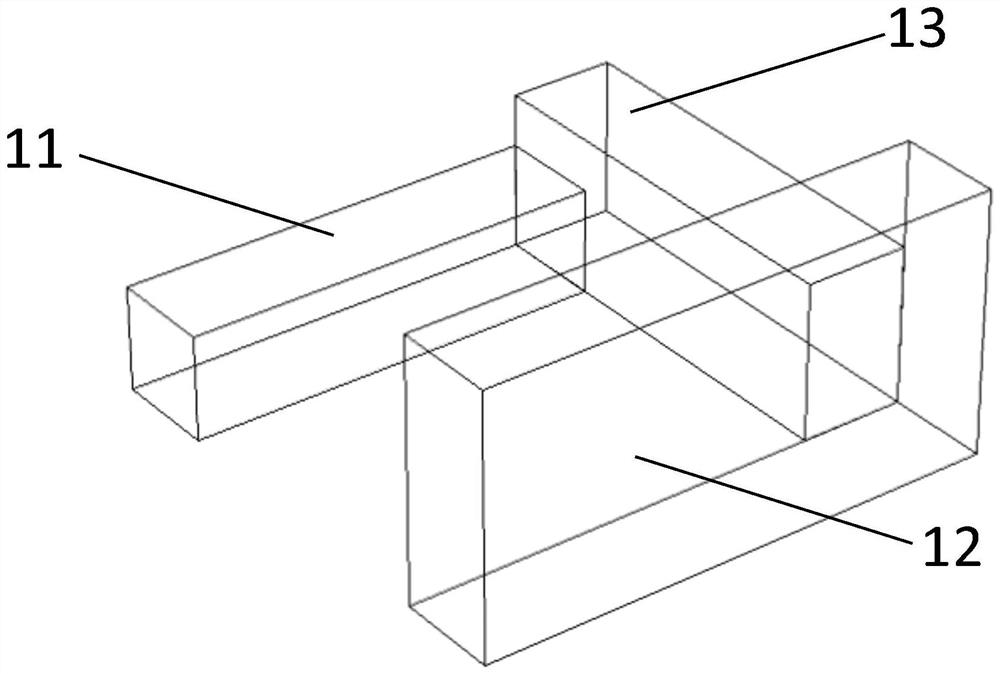

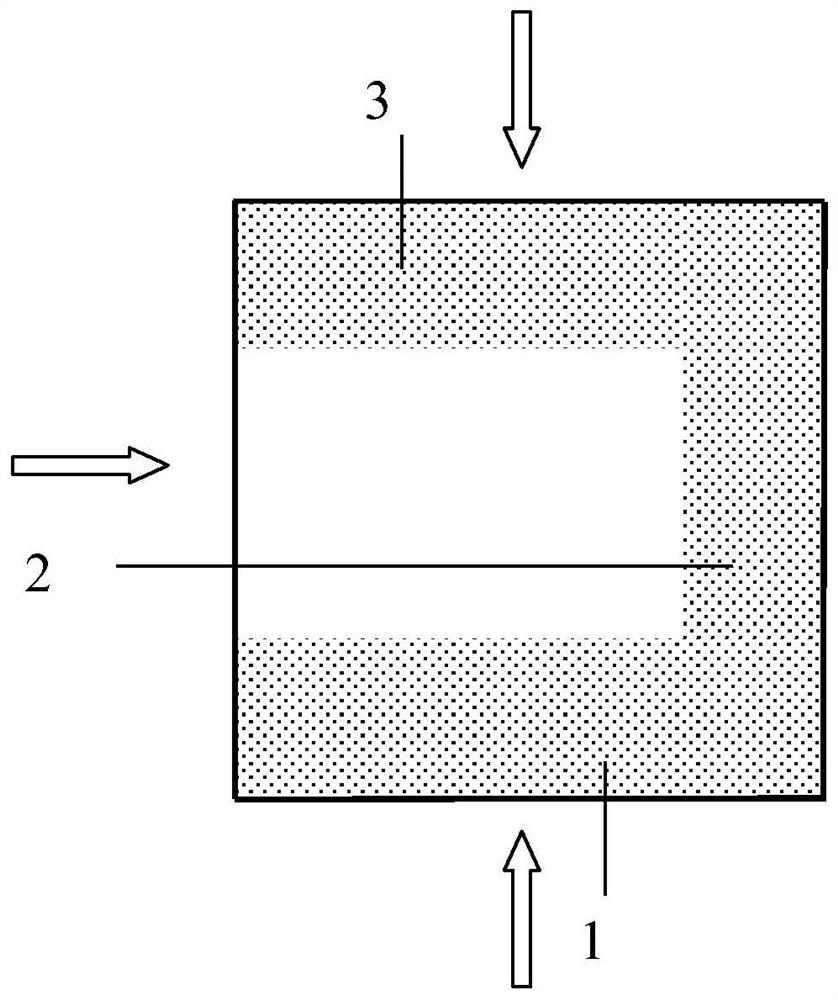

[0037] In order to solve the problems existing in the prior art, this embodiment provides a U-shaped structure that realizes circular dichroism, and uses a combination of electron beam exposure technology and oblique angle deposition technology to prepare chiral metal nano U with different height differences. type structure. Such as figure 1 The U-shaped structural unit that realizes circular dichroism is shown, and the structure is formed by plane connection of a plurality of periodic units with the same structure; each periodic unit contains a U-shaped structural unit; each structural unit It includes a horizontal body I11, a horizontal body II12, and a vertical body 13; one end of the horizontal body I11 is vertically connected to one end of the vertical body 13; one end of the horizontal body II12 is vertically connected to the other end of the vertical body 13; The horizontal body I11, horizontal body II12, and vertical body 13 are not on the same horizontal plane; the h...

Embodiment 2

[0056] After the U-shaped structure for realizing circular dichroism of the present invention is prepared based on Example 1 and the steps, a calculation simulation test is performed by using the three-dimensional finite element method (FEM) calculation software COMSOL Multiphysics. The specific setting parameters are as follows:

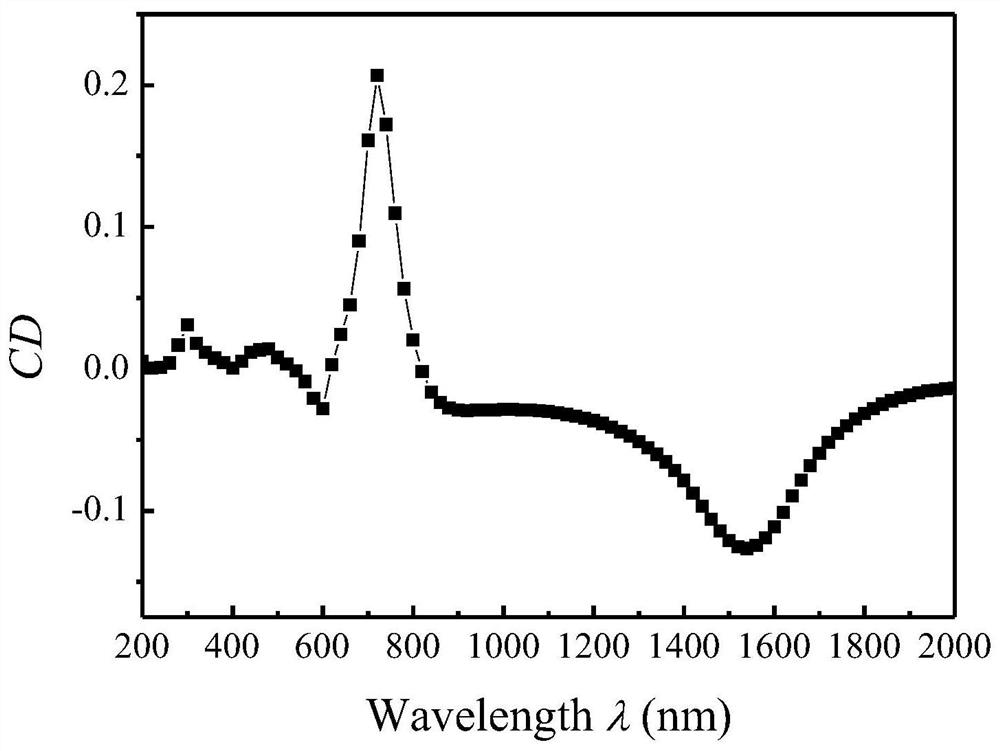

[0057] Such as figure 1 As shown, the size of each periodic unit is: length 400 nm×width 400 nm; the size of horizontal body I11 is: length 200 nm×width 40 nm×thickness 40 nm; the size of vertical body 13 is: length 200 nm×width 40 nm×thickness 60 nm ; The dimensions of the horizontal body II12 are: length 200nm×width 40nm×thickness 100nm. Such as image 3 Shown is the circular dichroism spectrum of the U-shaped structure of the embodiment of the present application. It can be seen that there are two larger CD signals at the wavelengths of 720nm and 1540nm, the magnitudes are: 20.69% and 12.66%, respectively. The structure proves that crossed el...

Embodiment 3

[0059] The preparation steps are the same as in Example 1, except that the metal material used is copper.

[0060] Gold, silver, and copper are different metal materials. The dielectric coefficients of the materials are different, and the corresponding effective refractive indices are different. The position of the transmission peak and valley of the metal micro-nano structure prepared therefrom is not affected, but the transmission intensity will be different. Gold is better than silver, and silver is better than copper. The circular dichroism lines collected by the chiral metal nanostructure prepared by gold, silver, and copper will have a small red and blue shift; but because the metal material is made of gold or copper and Metal materials use silver to achieve circular dichroism in the same mechanism, so the difference in the circular dichroism spectra of the prepared chiral metal nanostructures is not very large. Therefore, in this embodiment, copper is used instead of go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com