Construction method of anchor rod static pressure pile

A technology of anchor static pressure pile and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., and can solve problems such as adverse effects of structure use function, water seepage and waterproof problems at the pile head position, and achieve flexible construction and improved The effect of bearing capacity and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

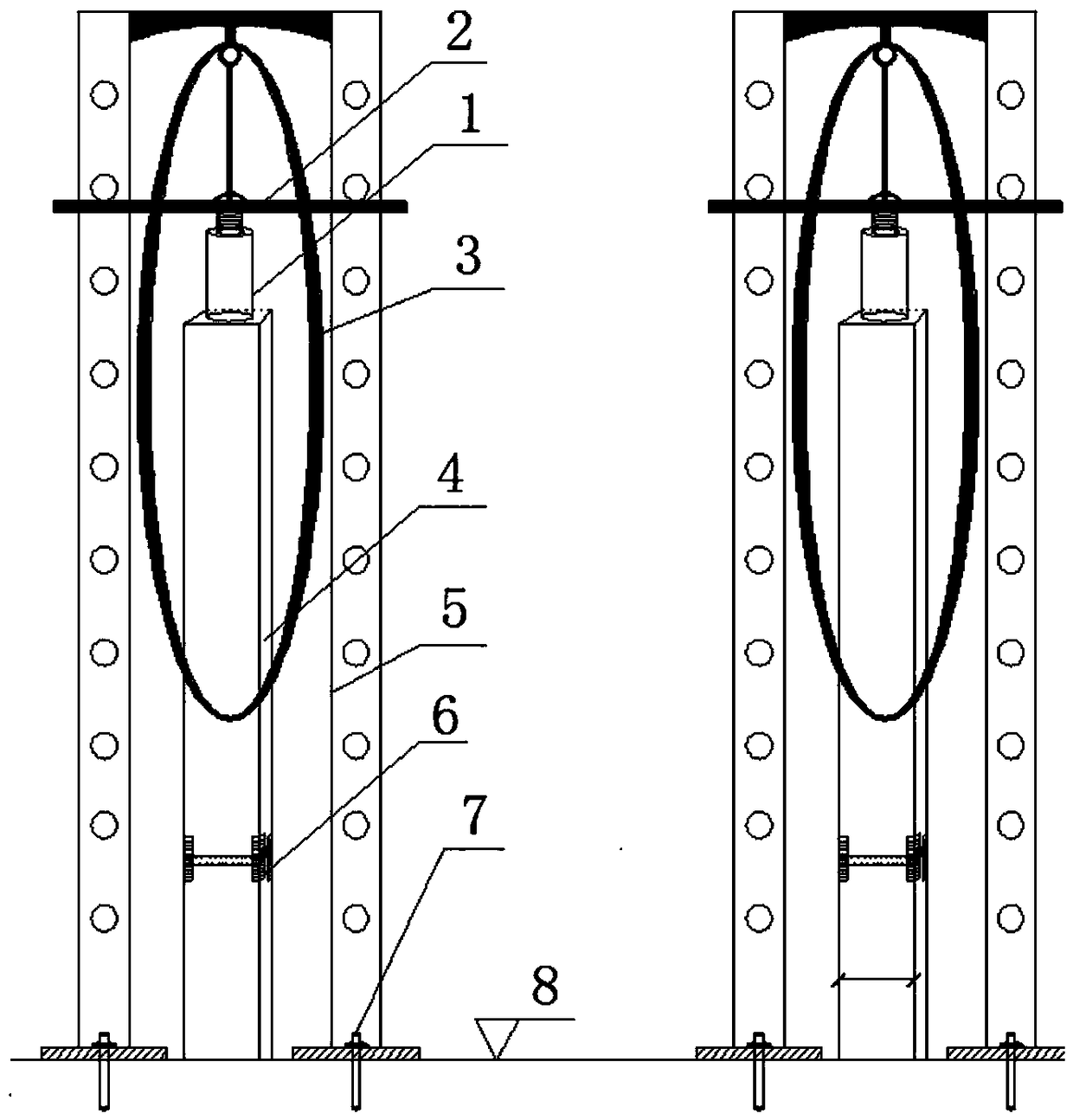

[0031] Example: such as figure 1 Shown is the structural diagram of the anchor static pressure pile using a jack pile. The construction method of the anchor static pressure pile specifically includes the following steps:

[0032] (1) Determine the pile location: According to the pile location layout diagram and the corresponding axis, use a tape measure combined with the theodolite to measure the positioning pile holes, place a small sample in each pile hole, and then paint the pile center and clearly mark the location;

[0033](2) Opening: positioning and drilling the pile holes;

[0034] (3) Check and clean the pile holes: check whether there is any deviation in the center position of the pile according to the drawing, and clean up the construction waste in the hole after the pile hole deviation is correct;

[0035] (4) Install the pressure pile reaction force frame: After the anchor pile frame 5 (ie the reaction force frame) is erected vertically, according to the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com