Fabric color fixing agent and preparation method thereof

A color-fixing agent and fabric technology, applied in the field of textile printing and dyeing, can solve the problems of difficulty in meeting printing and dyeing requirements, reduced color fastness, low stability, etc., and achieves improved dry and wet fastness, improved dry rubbing fastness, and no formaldehyde pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of fabric color fixing agent of the present invention, realize by following steps:

[0028] (1) Add the organic quaternary ammonium compound, cardanol glycidyl ether, and deionized water with halohydrin groups into the reaction kettle successively, start stirring, and start to heat up;

[0029] (2) Pour the unsaturated amide monomer and deionized water into the first high-level tank and stir to make it evenly mixed. Put the initiator and deionized water into the second high-level tank and stir to fully dissolve it. When the reaction When the temperature in the kettle rises to 85°C to 120°C, carry out nitrogen protection, then open the two high-level tanks, and drop the solutions of the two high-level tanks into the reaction kettle at a constant speed, and the dropping time is 3 to 6 hours;

[0030] (3) Then add epichlorohydrin dropwise to the reaction kettle, the dropping time is controlled within 1 to 3 hours, the temperature is maintained ...

Embodiment 1

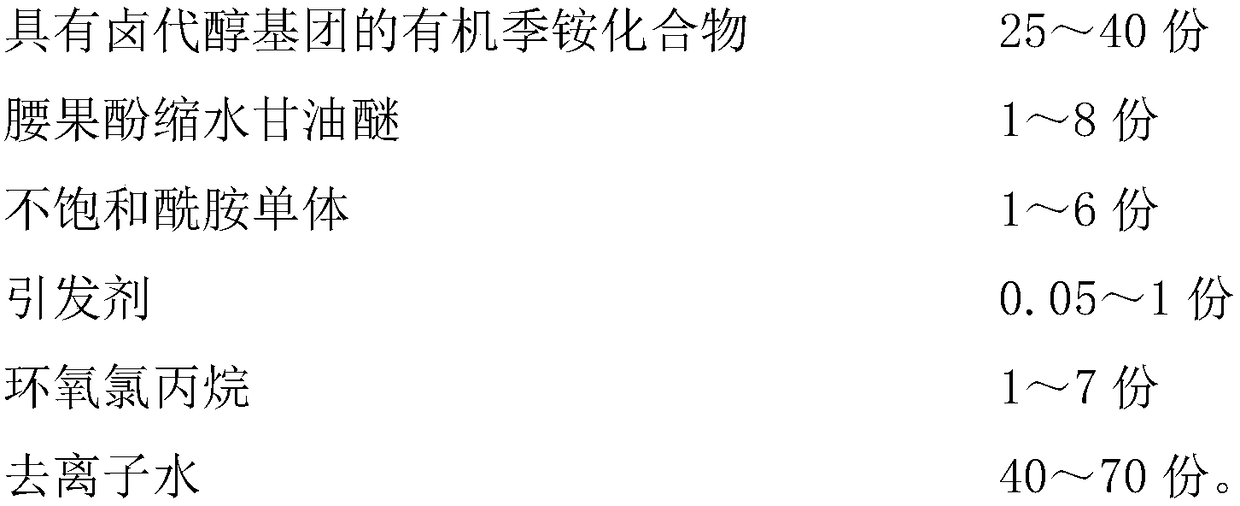

[0033] A fabric color fixing agent of the present invention is made of the following raw material components in proportions by mass:

[0034]

[0035] A kind of preparation method of fabric color fixing agent of the present invention, realize by following steps:

[0036] (1) Add 26 parts of (3-chloro-2-hydroxypropyl)trimethylammonium chloride, 1.5 parts of cardanol glycidyl ether, and 50 parts of deionized water into the reaction kettle in sequence, start stirring, and start heating heat up;

[0037] (2) Put 1.4 parts of N-vinylformamide and 15 parts of deionized water into the first high-level tank and stir to make them evenly mixed, and put 0.1 parts of ammonium persulfate and 4.9 parts of deionized water into the second high-level tank Neutralize and stir to make it fully dissolve. When the temperature in the reactor rises to 88°C, carry out nitrogen protection, then open the two high-level tanks, and drop the solutions of the two high-level tanks into the reactor at a ...

Embodiment 2

[0040] A fabric color fixing agent of the present invention is made of the following raw material components in proportions by mass:

[0041]

[0042] A kind of preparation method of fabric color fixing agent of the present invention, realize by following steps:

[0043] (1) Add 29 parts of (3-chloro-2-hydroxypropyl) dimethyl dodecyl ammonium chloride, 3 parts of cardanol glycidyl ether, and 39.5 parts of deionized water into the reaction kettle in sequence, and start stirring , and start to heat up;

[0044] (2) Put 1.9 parts of N-vinylacetamide and 15 parts of deionized water into the first high tank and stir to mix evenly, and put 0.25 parts of ammonium persulfate and 9.75 parts of deionized water into the second high tank Neutralize and stir to make it fully dissolve. When the temperature in the reactor rises to 92°C, perform nitrogen protection, then open the two high-level tanks, and drop the two high-level tank solutions into the reactor at a constant speed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com