AlCrSiN nano-composite coating resistant to high temperature and abrasion and preparation method thereof

A nano-composite coating, high-temperature wear-resistant technology, applied in the high-temperature wear-resistant AlCrSiN nano-composite coating and its preparation, pulse arc ion plating to prepare high-temperature wear-resistant AlCrSiN nano-composite coatings, can solve the problem that the deposition temperature is not accurate High requirements on control and bias power supply equipment, poor process stability and other problems, to achieve the effects of droplet control, excellent high temperature stability, and fast deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

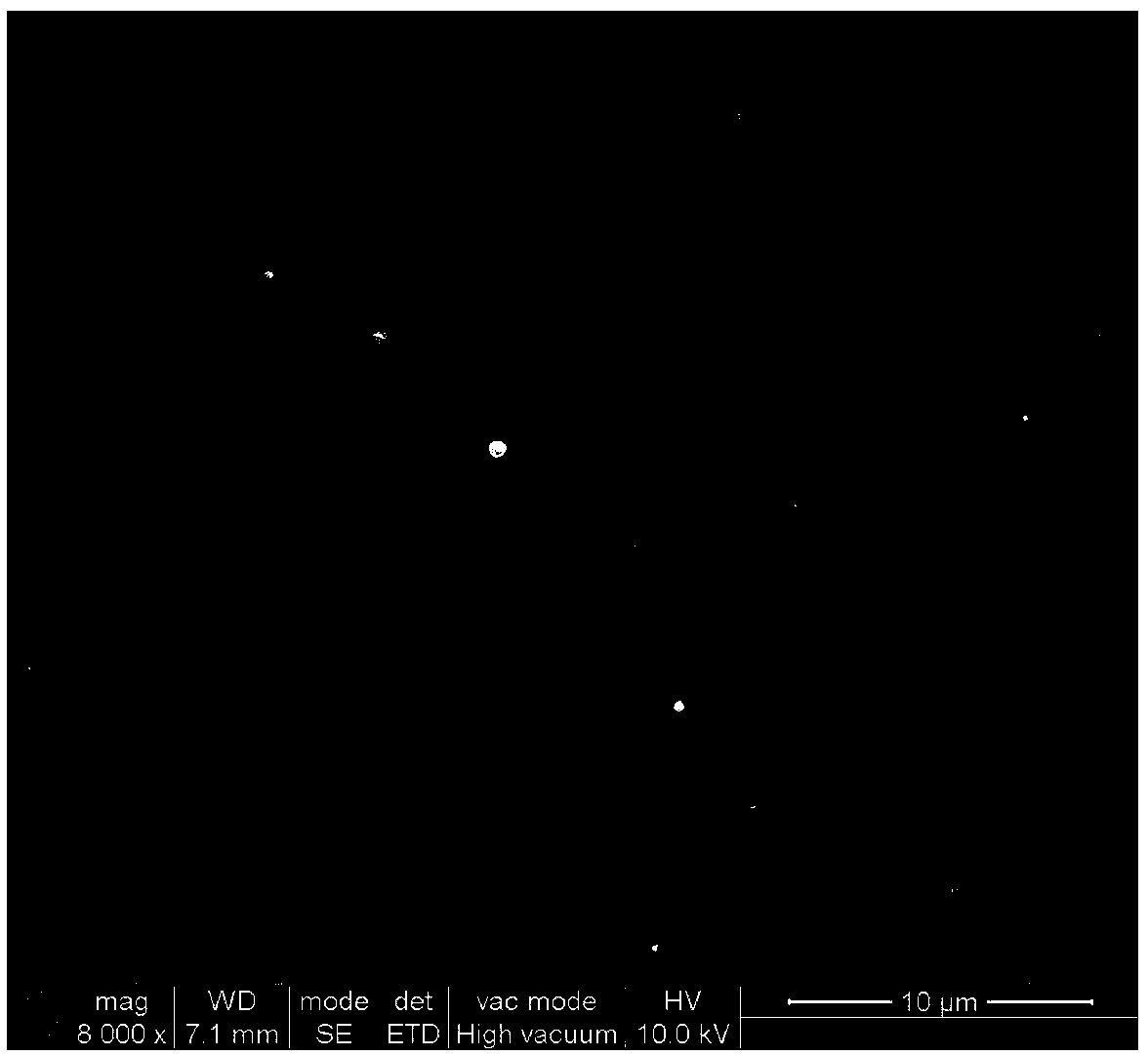

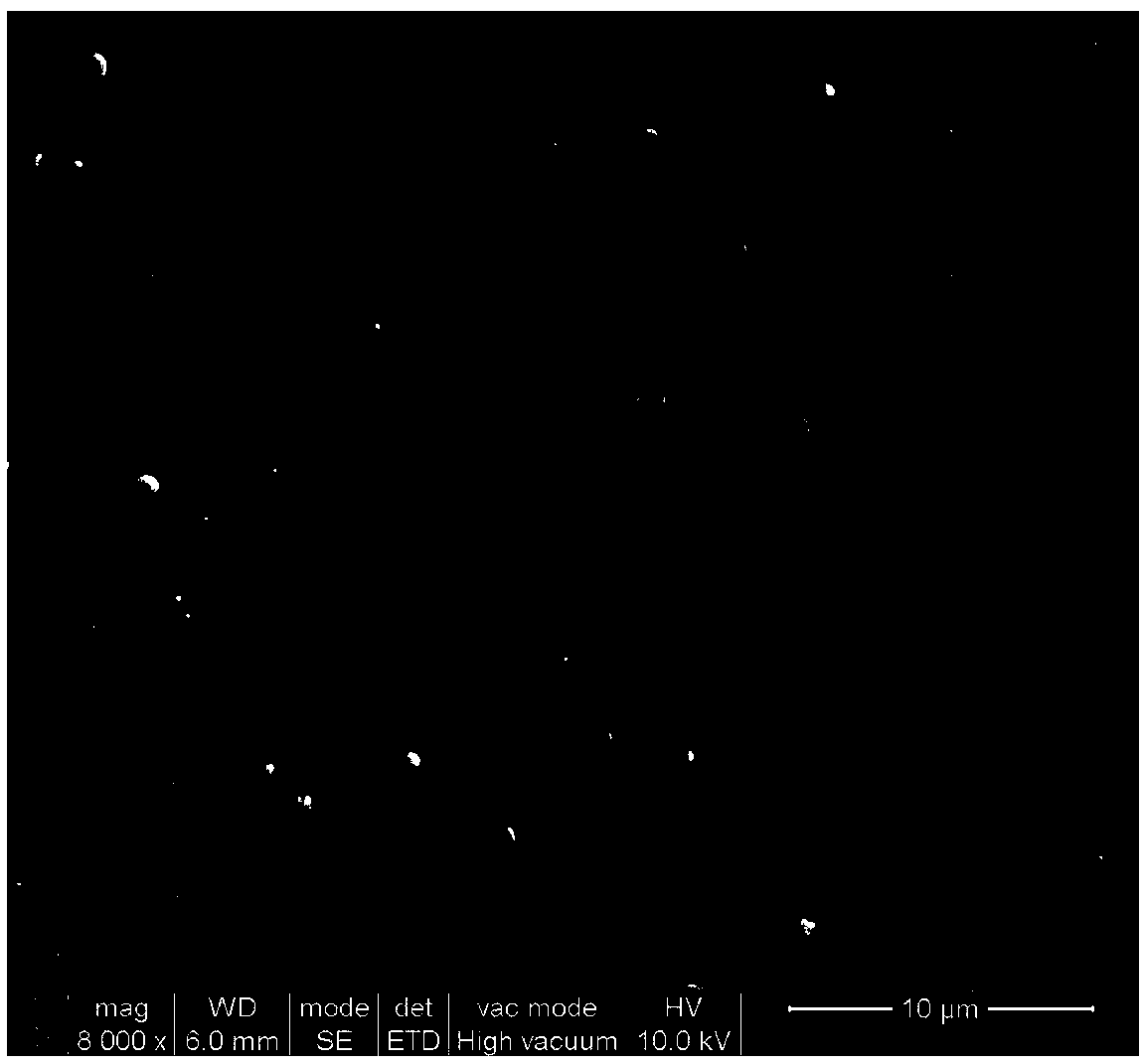

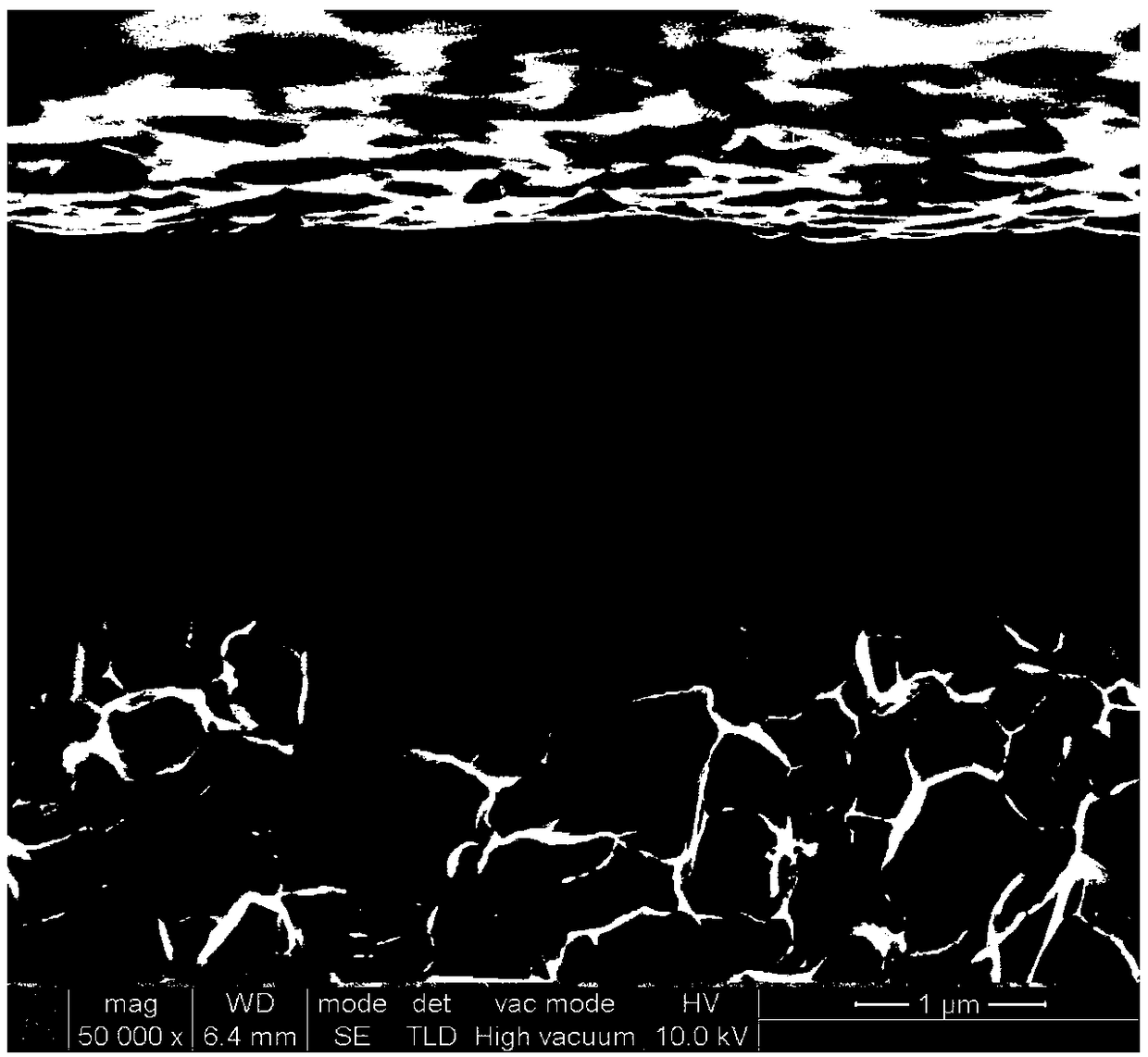

Image

Examples

Embodiment 1

[0038] The high-temperature and wear-resistant AlCrSiN nanocomposite coating is prepared by pulse arc ion plating, and its preparation includes the following steps:

[0039] 1) Polish the substrate, ultrasonically clean it with acetone and alcohol for 10 minutes, dry it with general nitrogen, and put it into a vacuum chamber.

[0040] 2) Put the substrate in the chamber, turn on the heater to raise the temperature of the chamber to 300-500°C, and evacuate the vacuum chamber to 5.0×10 -3 Pa; Then, feed 200 sccm argon and 50 sccm krypton, set the workpiece turret bias to -800V, and frequency 240kHz, and perform pulse etching on the substrate surface for 10 min; then, feed 150 sccm argon and 100 sccm krypton again, Set the bias voltage of the workpiece turret to -200V, the ion source current to 30A, and use the ion source to etch the substrate for 40 minutes;

[0041] 3) Adjust the bias voltage to -150V, feed 400sccm argon gas, ignite the Cr target, adjust the air pressure to 1P...

Embodiment 2

[0049] The high-temperature and wear-resistant AlCrSiN nanocomposite coating is prepared by pulse arc ion plating, and its preparation includes the following steps:

[0050] 1) Polish the substrate, ultrasonically clean it with acetone and alcohol for 10 minutes, dry it with general nitrogen, and put it into a vacuum chamber.

[0051] 2) Place the substrate in the chamber, turn on the heater to raise the temperature of the chamber to 300-500°C, and evacuate the vacuum chamber to 4.0×10 -3 Pa; then, feed 100 sccm argon and 100 sccm krypton, set the workpiece turret bias to -700V, and frequency 240 kHz, and perform pulse etching on the substrate surface for 10 min; then, feed 150 sccm argon and 50 sccm krypton again, Set the bias voltage of the workpiece turret to -200V, the ion source current to 30A, and use the ion source to etch the substrate for 45 minutes;

[0052] 3) Adjust the bias voltage to -90V, feed 400sccm argon gas, ignite the Cr target, adjust the air pressure to ...

Embodiment 3

[0060] The high-temperature and wear-resistant AlCrSiN nanocomposite coating is prepared by pulse arc ion plating, and its preparation includes the following steps:

[0061] 1) Polish the substrate, ultrasonically clean it with acetone and alcohol for 10 minutes, dry it with general nitrogen, and put it into a vacuum chamber.

[0062] 2) Place the substrate in the chamber, turn on the heater to raise the temperature of the chamber to 300-500°C, and evacuate the vacuum chamber to 5.0×10 -3 Pa; then, feed 100 sccm argon and 100 sccm krypton, set the workpiece turret bias to -700V, and frequency 240 kHz, and perform pulse etching on the substrate surface for 10 min; then, feed 150 sccm argon and 50 sccm krypton again, Set the bias voltage of the workpiece turret to -200V, the ion source current to 30A, and use the ion source to etch the substrate for 45 minutes;

[0063] 3) Adjust the bias voltage to -90V, feed 400sccm argon gas, ignite the Cr target, adjust the air pressure to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com