Preparation method of hollow sphere and aluminum alloy-based sound insulation material

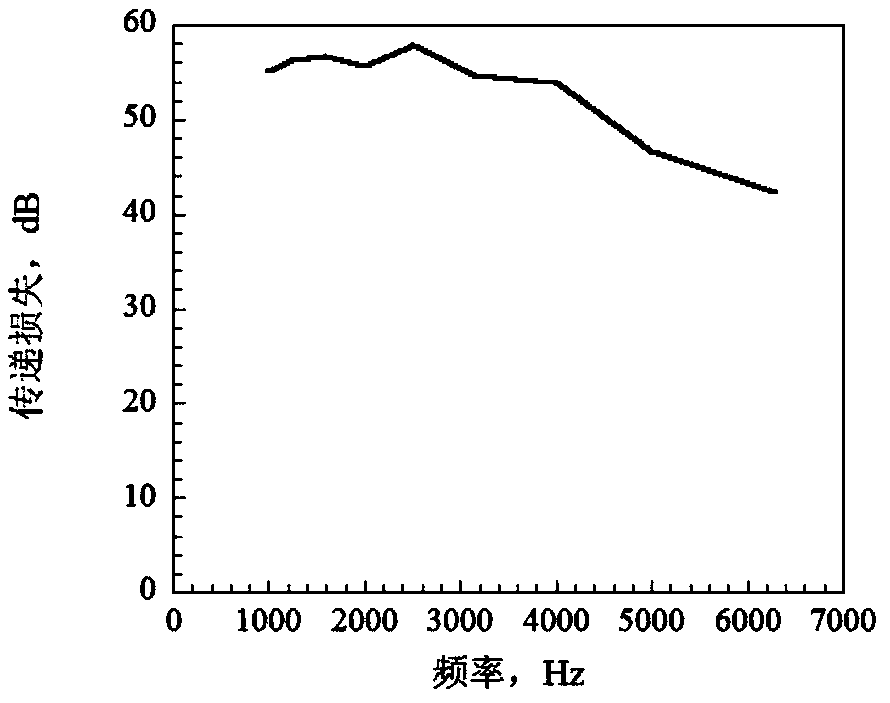

An aluminum alloy-based, sound-insulating material technology, applied in the field of composite material equipment, can solve problems such as complex operation process, and achieve the effects of simple operation process, reduced holes, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

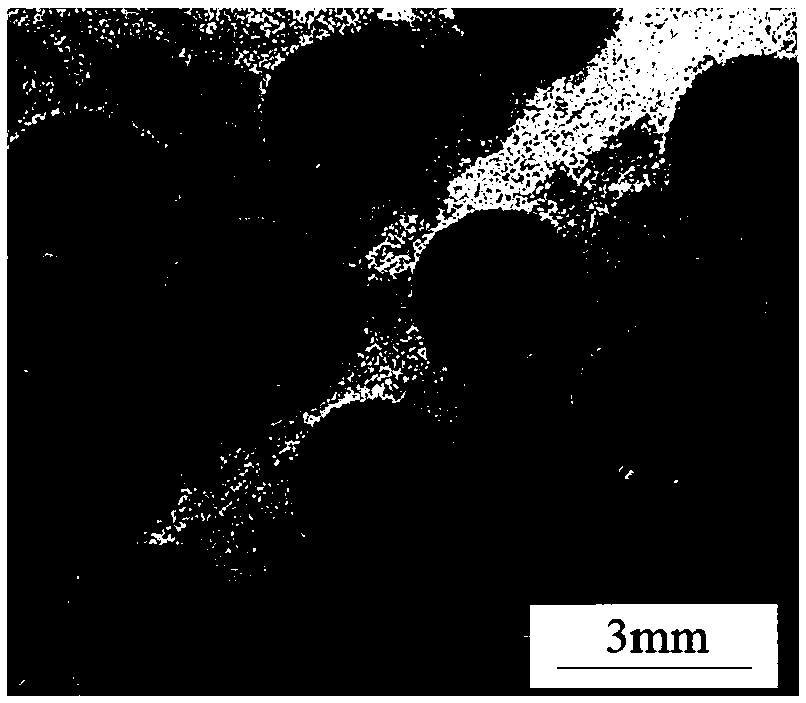

[0029] Weigh 3.71g (150 pieces) of 316L hollow spheres and 40g of 7075 aluminum alloy powder (D50, 10μm). Use dilute hydrochloric acid to clean the oxide film on the surface of the hollow ball, then use alcohol to further clean the hollow ball in an ultrasonic cleaner, and dry the cleaned hollow ball with a hair dryer for later use. The cleaned hollow balls and the weighed 7075 aluminum alloy powder are prefabricated in a stainless steel mold sprayed with boron nitride, and the hollow balls are randomly and evenly distributed inside the matrix.

[0030] Put the prefabricated mold into a vacuum hot-press sintering furnace for hot-press sintering. The entire heating and cooling process is carried out in a vacuum environment. Heat the sample to 500°C at a heating rate of 6°C / min, and keep the pressure at 16MPa during the heating process; keep it at 500°C for 30 minutes, and keep the pressure at 16MPa during the holding process; then heat the sample at a heating rate of 3°C / min ...

Embodiment 2

[0037] Weigh 2.47g (100 pieces) of 316L hollow spheres and 30g of 7075 aluminum alloy powder (D50, 10μm). Use dilute hydrochloric acid to clean the oxide film on the surface of the hollow ball, then use alcohol to further clean the hollow ball in an ultrasonic cleaner, and dry the cleaned hollow ball with a hair dryer for later use. The cleaned hollow balls and the weighed 7075 aluminum alloy powder are prefabricated in a stainless steel mold sprayed with boron nitride, and the hollow balls are randomly and evenly distributed inside the matrix.

[0038]Put the prefabricated mold into a vacuum hot-press sintering furnace for hot-press sintering. The entire heating and cooling process is carried out in a vacuum environment. Heat the sample to 530°C at a heating rate of 8°C / min, and keep the pressure at 20MPa during the heating process; keep it at 530°C for 30 minutes, and keep the pressure at 20MPa during the holding process; then heat the sample at a heating rate of 2°C / min T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com