Fermented fructus mori wine and method for preparing same

A fermented, mulberry wine technology, applied in the preparation of alcoholic beverages, biochemical equipment and methods, methods based on microorganisms, etc., can solve the problems of excessive volatile acid, easy oxidation of aging, and easy infection of acetic acid bacteria, etc., to achieve good alcohol Fermentation, facilitate the effect of liquor filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] (1) Screening and sterilization: the mulberries are screened, washed with cold water at 10°C, sterilized with 125mg / L sulfur dioxide solution, and the whole fruit is crushed; the mulberries used for production are more than eight mature, fresh, free from rot, diseases and insect pests, and the juice yield ≥55%, total sugar 100-120g / L, total acid 3-5g / L mulberries.

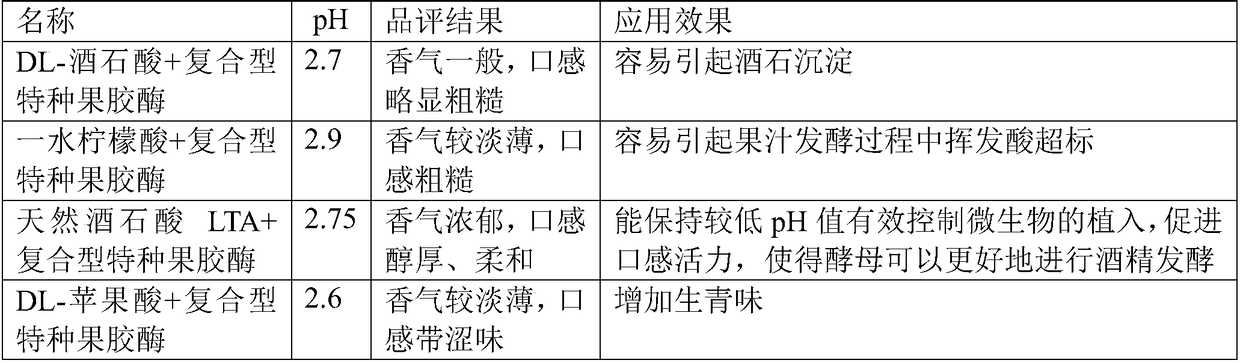

[0097] (2) The adjustment of pulp composition is carried out simultaneously with low-temperature enzymatic hydrolysis: 2g / L (final concentration) food-grade natural tartaric acid LTA (Shanghai Jietu Industry and Trade Co., Ltd.) is added to the broken mulberry whole fruit to adjust the pH of the mulberry juice to 2.5 and 22mg / L (final concentration) compound special pectinase REDstyle TM (French Laman Group, the following examples are the same) Enzymolysis at a temperature of 13.7°C for 5.5 hours, the yield of fruit juice is 60%, and the enzymolysis product is obtained; keeping a low pH value effectively con...

Embodiment 2

[0114] (1) Screening and sterilization: the mulberries are screened, washed in cold water at 10°C, sterilized with 125mg / L sulfur dioxide solution, and the whole fruit is crushed; the mulberries used for production are more than 80% mature, fresh, free of rotten fruit, diseased fruit, and the juice yield rate ≥55%, total sugar 100-120g / L, total acid 3-5g / L mulberries.

[0115] (2) The adjustment of pulp composition and low-temperature enzymatic hydrolysis are carried out simultaneously: add 2.5g / L (final concentration) food-grade natural tartaric acid LTA (Shanghai Jietu Industry and Trade Co., Ltd.) to the crushed whole mulberry fruit to adjust the pH of mulberry juice 2.75 and 23mg / L (final concentration) compound special pectinase (French Laman Group) was enzymolyzed at a temperature of 14.5°C for 6 hours, and the yield of juice was 61.5%, and the enzymolyzed product was obtained.

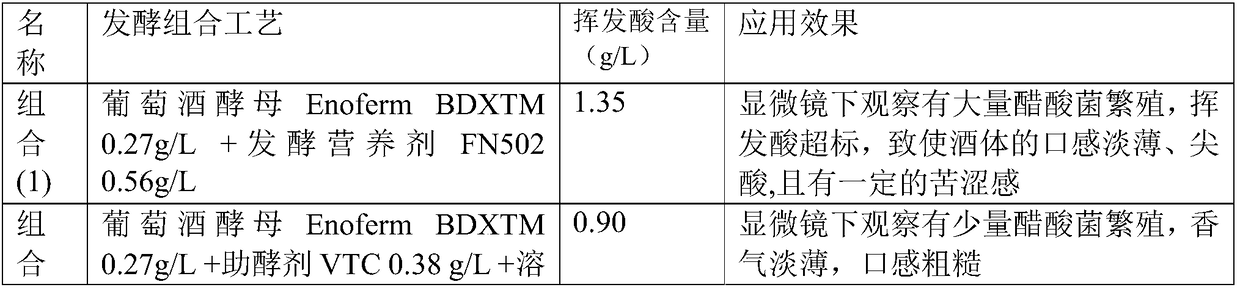

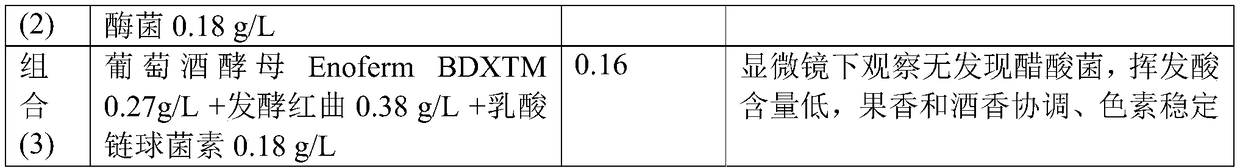

[0116] (3) Temperature-controlled fermentation: add 0.30g / L (final concentration) wine yeast...

Embodiment 3

[0128] (1) Screening and sterilization: the mulberries are screened, washed in cold water at 10°C, sterilized with 125mg / L sulfur dioxide solution, and the whole fruit is crushed; the mulberries used for production are more than 80% mature, fresh, free of rotten fruit, diseased fruit, and the juice yield rate ≥55%, total sugar 100-120g / L, total acid 3-5g / L mulberries.

[0129] (2) The pulp component adjustment and low-temperature enzymatic hydrolysis are carried out simultaneously: 3g / L (final concentration) food-grade natural tartaric acid LTA (Shanghai Jietu Industry and Trade Co., Ltd.) is added to the broken mulberry whole fruit to adjust the pH of the mulberry juice to 3.0 and 24mg / L (final concentration) compound special pectinase (French Laman Group) was enzymolyzed at a temperature of 15.3°C for 7.5 hours, the yield of juice was 62%, and the enzymolyzed product was obtained; keep a low pH value to effectively control microorganisms The implantation of the yeast allows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com