Concrete self-curing agent and preparation method and using method thereof

A concrete and self-curing technology, which is used in the fields of concrete curing agent, concrete curing agent preparation, concrete self-curing agent, and concrete additives, can solve the problem of not giving a guiding scheme, and achieve the reduction of saturated steam pressure, improvement of design requirements and Quality requirements, the effect of reducing moisture migration channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

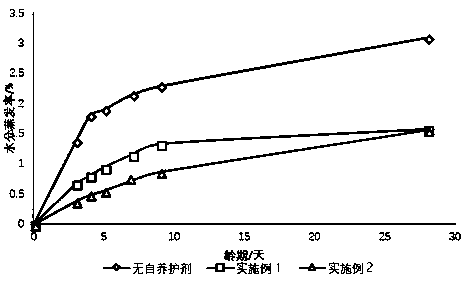

[0026] Example 1: The concrete self-curing agent of the present invention is made from the following raw materials by mass: 70 parts of evaporation inhibitor, 20 parts of micropore blocking agent, and 10 parts of water locking agent.

[0027] Described evaporation inhibitor uses the mixture of tetraethylene glycol and polyethylene glycol, and polyethylene glycol selects polyethylene glycol 400 for use, and the mass ratio of tetraethylene glycol and polyethylene glycol 400 is 1 : 1; the micropore blocking agent selects the mixture of silane / siloxane mixture and alkyl alkoxy silicon emulsion, namely the mixture of Dow Corning Z-6689 waterproofing agent and Momentive SC-50 waterproofing agent, Dow Corning Z-6689 The mass ratio of waterproofing agent to Momentive SC-50 waterproofing agent is 1:1; the water-locking agent is a mixture of polyvinyl alcohol and polyethylene oxide, and the quality of polyvinyl alcohol and polyethylene oxide is equal to The ratio is 1:1. See Table 1 fo...

Embodiment 2

[0031] Example 2: The concrete self-curing agent of the present invention is made from the following raw materials by mass: 50 parts of evaporation inhibitor, 45 parts of micropore blocking agent, and 5 parts of water locking agent.

[0032] Described evaporation inhibitor uses the mixture of tetraethylene glycol and polyethylene glycol, and polyethylene glycol selects polyethylene glycol 400 for use, and the mass ratio of tetraethylene glycol and polyethylene glycol 400 is 1 : 10; the described micropore blocking agent selects the mixture of silane / siloxane mixture and alkyl alkoxy silicon emulsion, namely the mixture of Dow Corning Z-6689 waterproofing agent and Momentive SC-50 waterproofing agent, Dow Corning Z-6689 The mass ratio of the waterproofing agent to Momentive SC-50 waterproofing agent is 1:50; the water-locking agent is a mixture of polyvinyl alcohol and polyethylene oxide, and the mass of polyvinyl alcohol and polyethylene oxide is equal. The ratio is 1:5. See ...

Embodiment 3

[0036] Example 3: The concrete self-curing agent of the present invention is made from the following raw materials by mass: 60 parts of evaporation inhibitor, 35 parts of micropore blocking agent, and 5 parts of water locking agent.

[0037] Described evaporation inhibitor is the combination of two kinds of raw materials of pentaerythritol and diethylene glycol monobutyl ether; the mass ratio of pentaerythritol and diethylene glycol monobutyl ether is 1: 2; Combination of three raw materials: triethoxysilane, methylphenyl silicone resin and silane coupling agent KH560; mass ratio of n-octyltriethoxysilane, methylphenyl silicone resin and silane coupling agent KH560 is 1:1:2; the water-locking agent is a combination of two raw materials, hydroxypropyl cellulose and polyacrylamide; the mass ratio of hydroxypropyl cellulose and polyacrylamide is 1:1.

[0038] The preparation method of the concrete self-curing agent comprises the following process steps: adding 20 parts of pentaer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com