Sludge and shale thermal insulation microporous brick and preparation method thereof

A shale and sludge technology, which is applied in the field of sludge shale thermal insulation microporous bricks and its preparation, can solve problems such as environmental and human health threats, air and water pollution, and potential safety hazards, and achieve low drying shrinkage, Effects of environmental load reduction, good mechanical properties and thermal insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

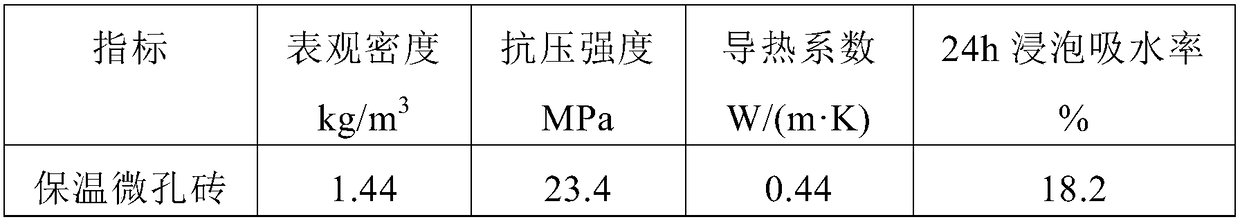

Embodiment 1

[0029] A preparation method of sludge shale thermal insulation microporous brick, comprising the following steps:

[0030] S1: Put the sludge with a moisture content of more than 90% from the sewage treatment plant in the drying plant, turn it over for 3 days, and then dry the sludge to make the moisture content lower than 10%, and obtain the sludge block;

[0031] S2: Put shale, sludge, and coal gangue in three-stage crushers of jaw crusher, hammer crusher, and fine crusher to obtain shale particles, sludge particles, and coal gangue particles, and the particle size is less than 5mm ;

[0032] S3: Mix the shale particles, sludge particles, and coal gangue particles with a mass ratio of 75%, 15%, and 10% in terms of absolute dry mass conversion, and then sieve the mixture powder after grinding in a planetary ball mill for 15-20 minutes ; After grinding, the powder is sieved in a 2mm sieve and a 0.2mm sieve for the first time and the second time. and the secondary sieved powd...

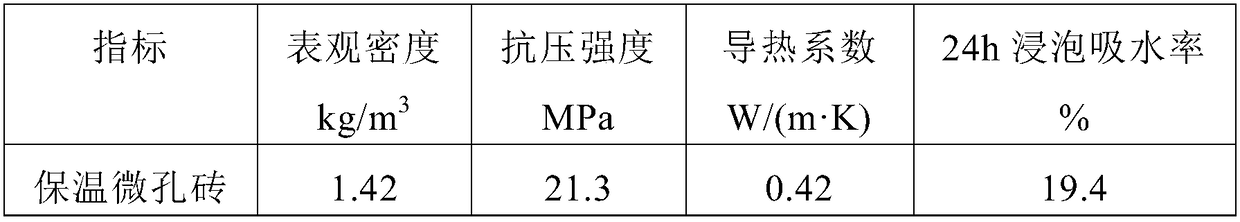

Embodiment 2

[0041] A preparation method of sludge shale thermal insulation microporous brick, comprising the following steps:

[0042] S1: Put the sludge with a moisture content of more than 90% from the sewage treatment plant in the drying plant, turn it over for 3 days, and then dry the sludge to make the moisture content lower than 10%, and obtain the sludge block;

[0043] S2: Put shale, sludge, and coal gangue in three-stage crushers of jaw crusher, hammer crusher, and fine crusher to obtain shale particles, sludge particles, and coal gangue particles, and the particle size is less than 5mm ;

[0044] S3: Mix the shale particles, sludge particles, and coal gangue particles at a mass ratio of 70%, 15%, and 15% after absolute dry mass conversion, and then grind them in a planetary ball mill for 15-20 minutes and sieve to obtain a mixture powder ; After grinding, the powder is sieved in a 2mm sieve and a 0.2mm sieve for the first time and the second time. and the secondary sieved powd...

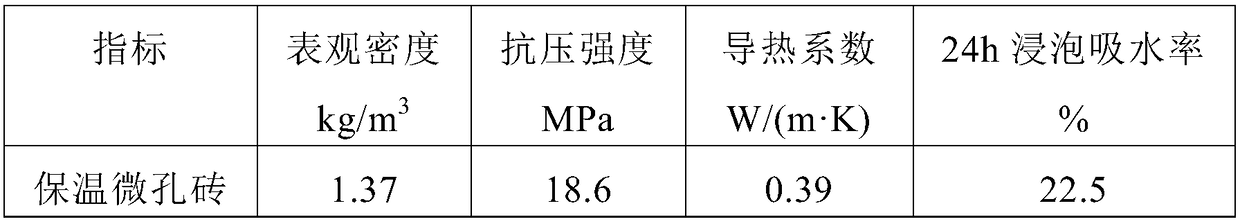

Embodiment 3

[0053] A preparation method of sludge shale thermal insulation microporous brick, comprising the following steps:

[0054] S1: Put the sludge with a moisture content of more than 90% from the sewage treatment plant in the drying plant, turn it over for 3 days, and then dry the sludge to make the moisture content lower than 10%, and obtain the sludge block;

[0055] S2: Put shale, sludge, and coal gangue in three-stage crushers of jaw crusher, hammer crusher, and fine crusher to obtain shale particles, sludge particles, and coal gangue particles, and the particle size is less than 5mm ;

[0056] S3: Mix the shale particles, sludge particles, and coal gangue particles with a mass ratio of 70%, 20%, and 10% after conversion according to the absolute dry mass, and then grind them in a planetary ball mill for 15-20 minutes and sieve to obtain a mixture powder ; After grinding, the powder is sieved in a 2mm sieve and a 0.2mm sieve for the first time and the second time. and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com