Method for promoting coking wastewater treatment through photocatalytic electrode coupled microbial fuel cell

An electrode coupling, coking wastewater technology, applied in special compound water treatment, biochemical fuel cells, biological water/sewage treatment, etc., to achieve the effect of reducing concentration, low energy consumption and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

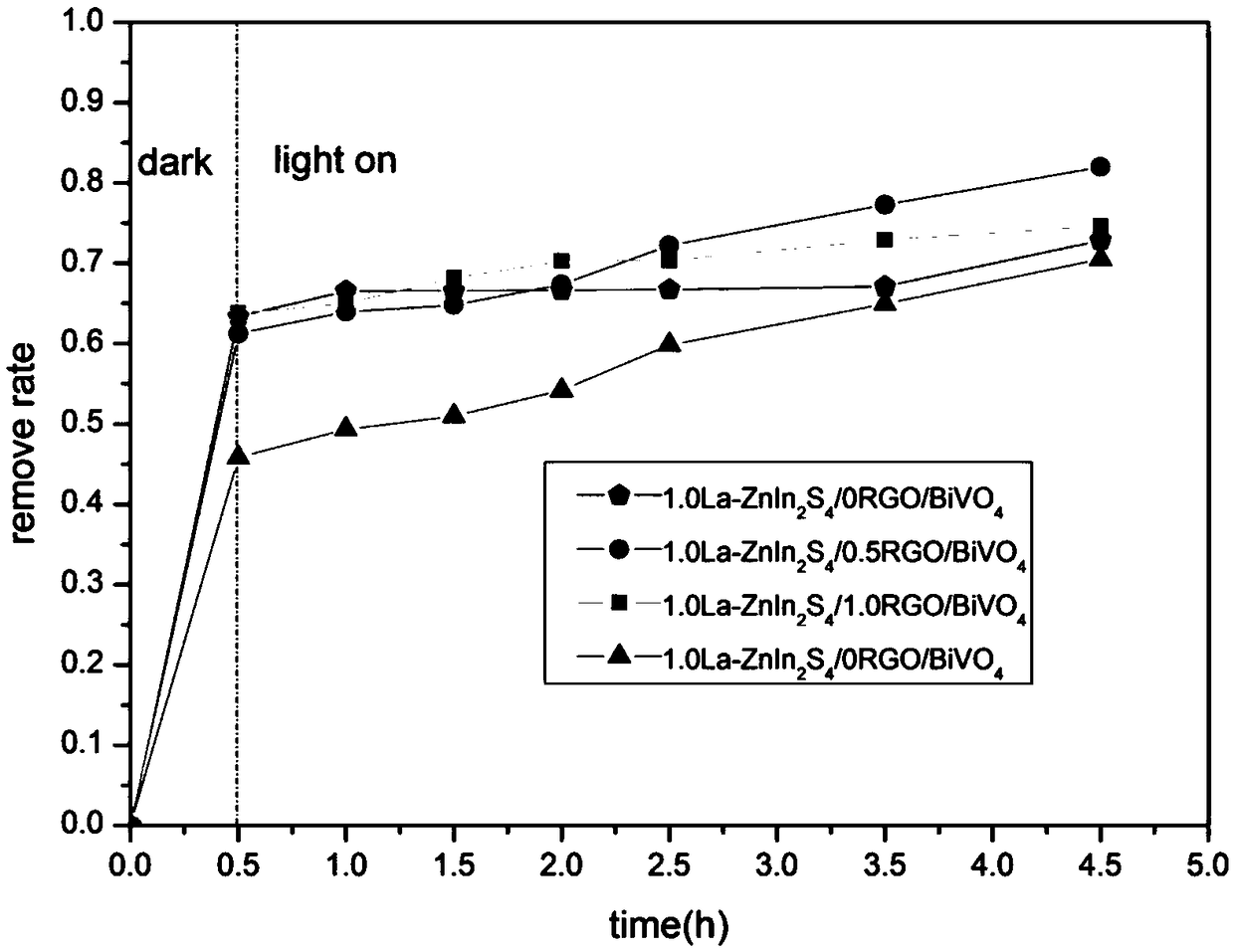

[0021] Example 1: Catalysts with different RGO contents degrade coking wastewater

[0022] In the double-chamber cuboid reactor system with photocatalytic membrane electrodes coupled with microbial fuel cells, both the membrane module and the halogen tungsten lamp are put into the system, and the carbon rods are put into the microbial anode separated by the proton exchange membrane, and the photocatalyst contacts The system contains NaHSO 3The coking waste water is photocathode, there is an aeration head at the bottom of the cathode chamber for continuous aeration, connect the top of the membrane with crocodile clips, put the halogen tungsten lamp into the reaction device, turn off the power supply of the halogen tungsten lamp before the reaction, and perform a dark reaction for 0.5h first After that, turn on the power of the tungsten-halogen lamp and react with light for 4 hours. After the reaction starts, take samples with a pipette every 0.5 hours for the first 2.5 hours, a...

Embodiment 2

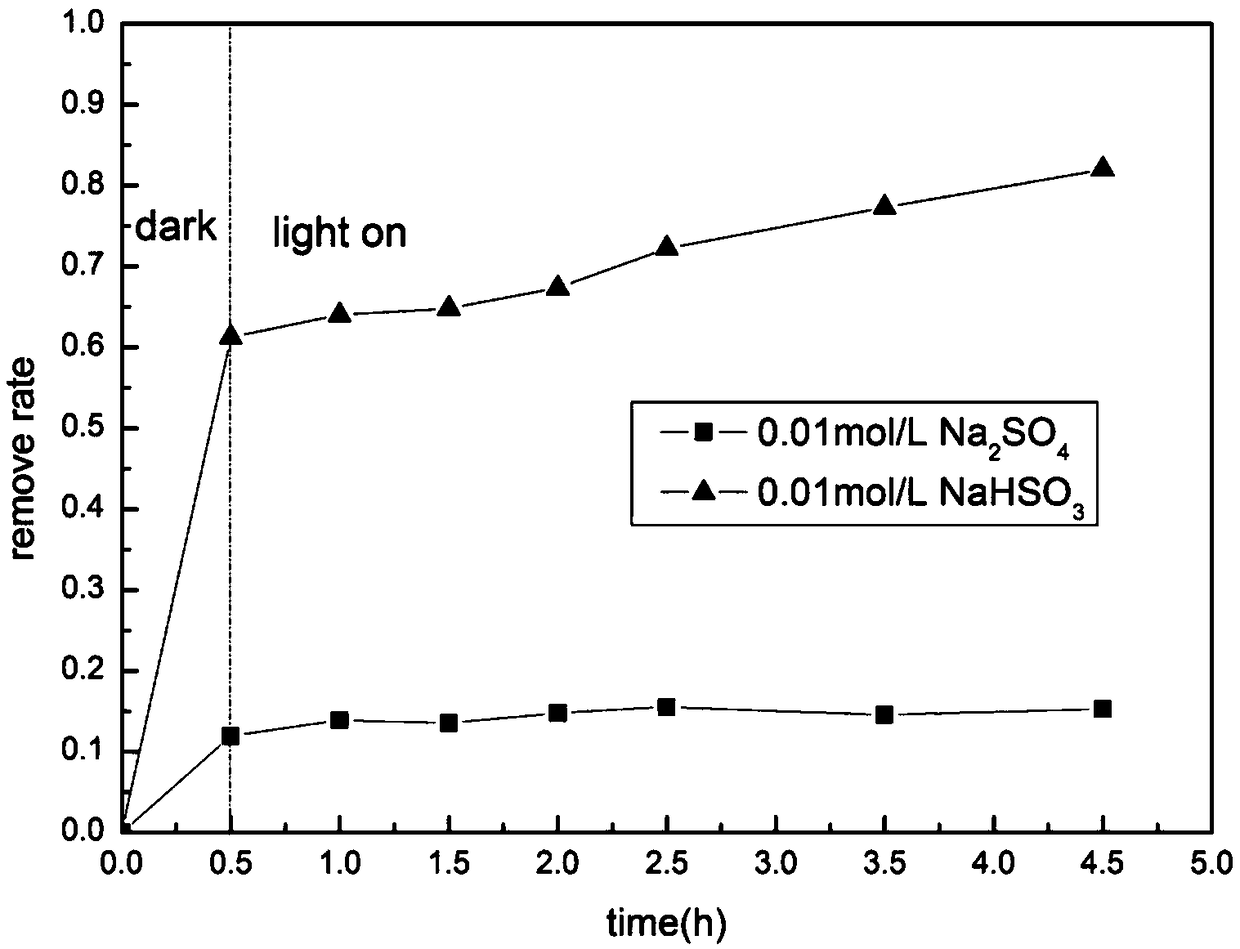

[0024] Embodiment two: containing the same concentration of NaHSO 3 and Na 2 SO 4 system to degrade coking wastewater

[0025] In the dual-chamber rectangular parallelepiped reactor system with photocatalytic membrane electrodes coupled with microbial fuel cells, both the membrane module and the tungsten halogen lamp are put into the system, and carbon rods are put into the microbial anode separated by a proton exchange membrane. Catalyst contact system containing NaHSO 3 The coking wastewater is the photocathode (the other is the photocatalyst contact system containing Na 2 SO 4 The coking wastewater is a photocathode, and other conditions are the same) There is an aeration head at the bottom of the cathode chamber for continuous aeration, connect the top of the membrane with crocodile clips, put the halogen tungsten lamp into the reaction device, turn off the power supply of the halogen tungsten lamp before the reaction, and first carry out 0.5 After the dark reaction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com