Composite material of sub-group metals compounded with MXenes and preparation method and application of composite material

A metal composite and composite material technology, applied in the field of MXenes composite materials, to achieve the effect of broadening the application range, low reaction temperature and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

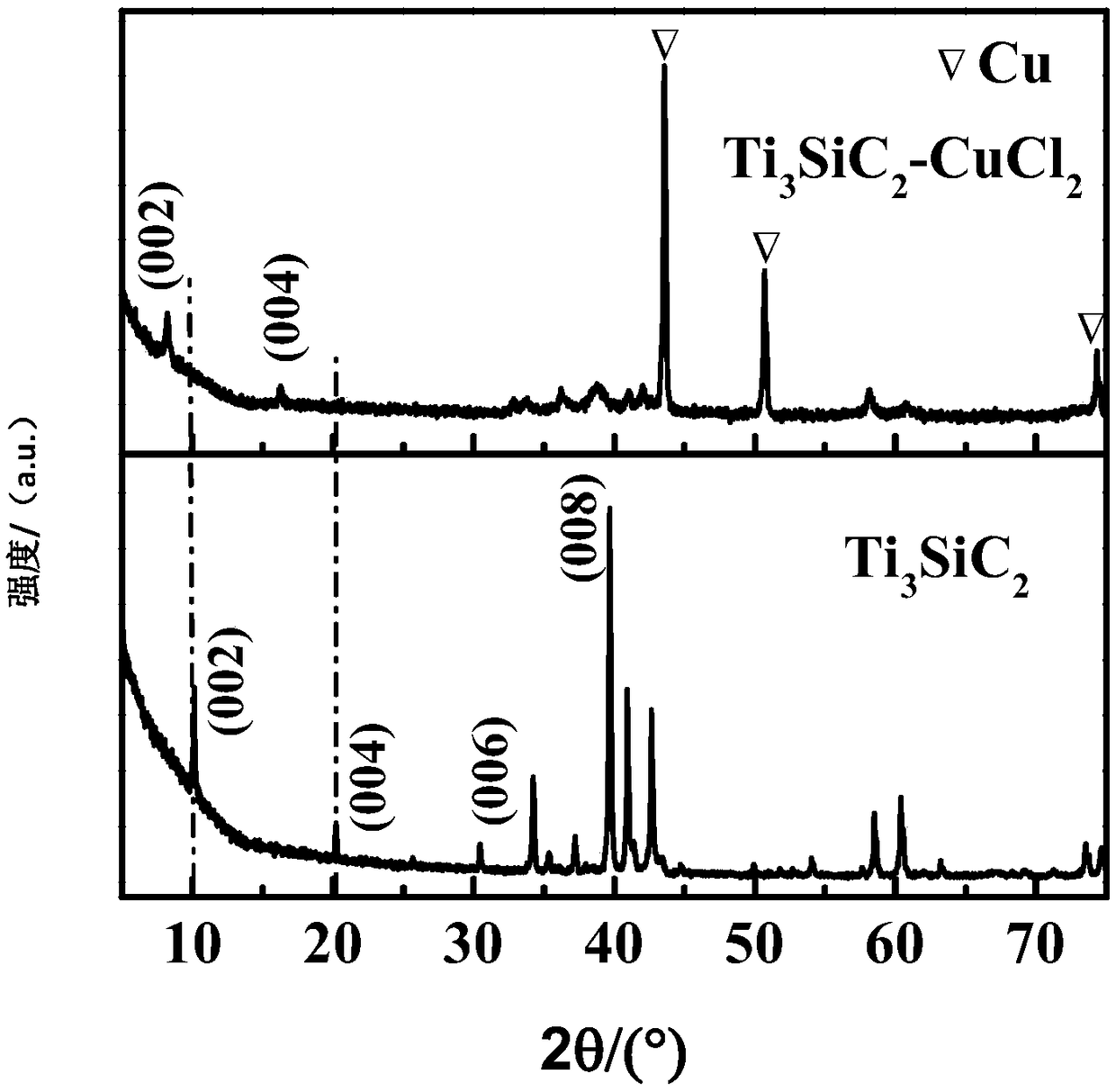

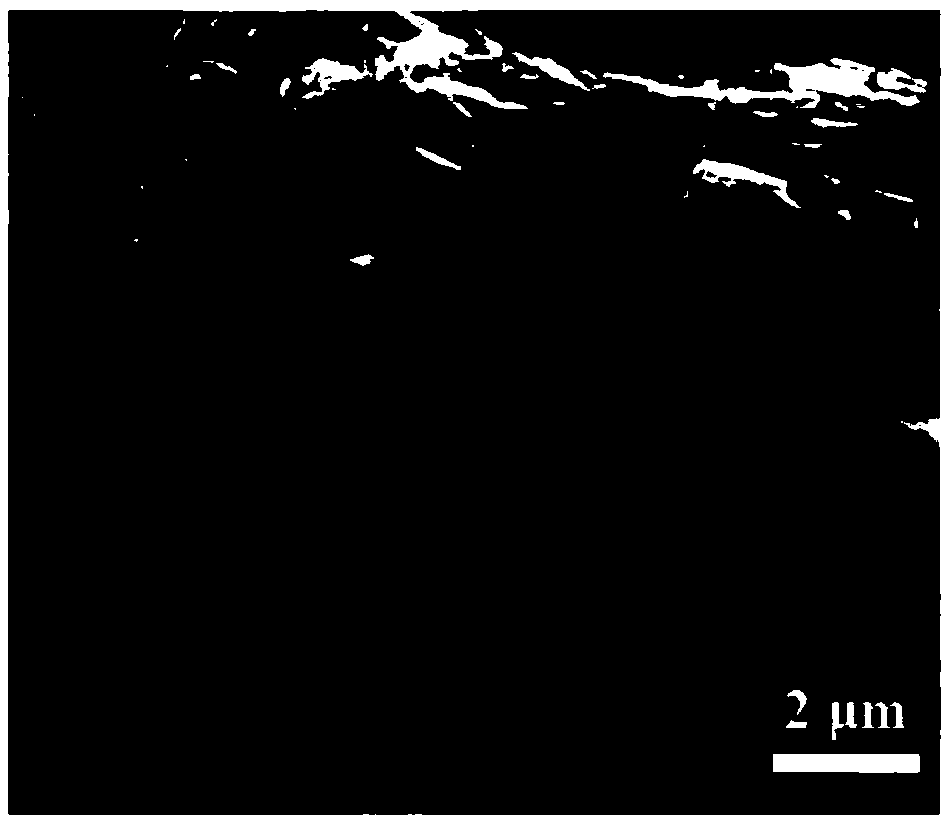

[0060] In this embodiment, the composite material of subgroup metal composite MXenes is composed of metal Cu and Ti 3 C 2 Composition, Cu particles coated in situ on Ti 3 C 2 Surface and interlayer, whose chemical formula is Cu-Ti 3 C 2 , the Cu-Ti 3 C 2 The concrete preparation method of composite material is as follows:

[0061] (1) According to the precursor M n+1 AX n The molar ratio of phase material, subgroup metal salt and inorganic salt is 1:1.5:4 to weigh 1gTi 3 SiC 2 Powder, 2.1g CuCl 2 powder, 1.2g NaCl powder and 1.55g KCl powder, grind them for 5min and put them into an alumina crucible;

[0062] (2) Put the uniformly mixed composite powder into the crucible, and react at 800°C for 1 hour under an inert atmosphere; after the reaction is completed, take out the reactant from the crucible;

[0063] (3) Wash the reaction product with deionized water: put the reaction product in a beaker, add deionized water, stir and ultrasonically clean for 10 minutes, t...

Embodiment 2

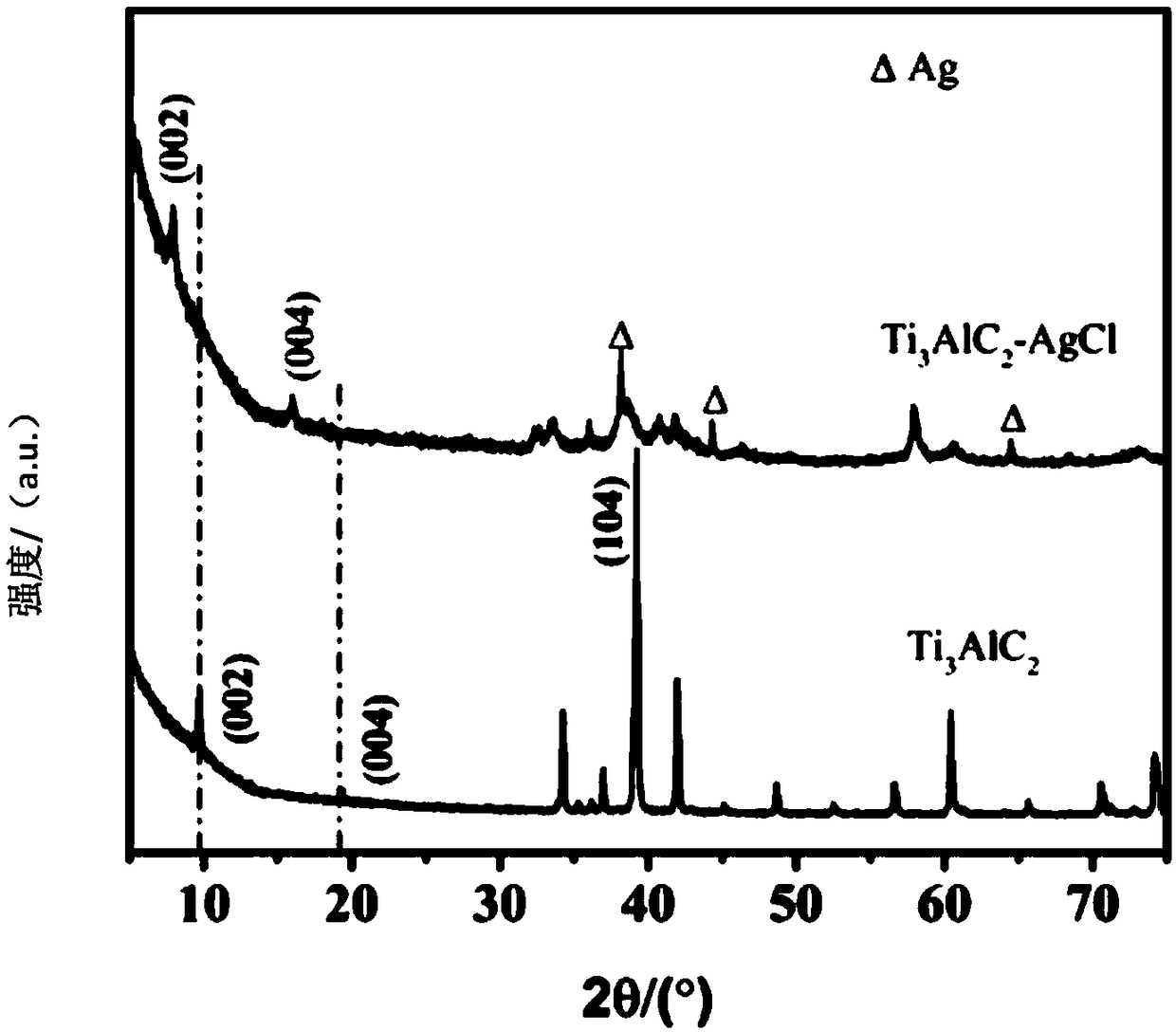

[0067] In this embodiment, the composite material of subgroup metal composite MXenes is made of metal Ag and Ti 3 C 2 Composition, Ag particles coated in situ on Ti 3 C 2 Surface and interlayer, whose chemical expression is Ag-Ti 3 C 2 , the Ag-Ti 3 C 2 The concrete preparation method of composite material is as follows:

[0068] (1) According to the precursor M n+1 AX n The molar ratio of phase material, subgroup metal salt and inorganic salt is 1:6:0, and 1gTi is weighed 3 AlC 2 powder and 4.5gAgCl powder, grind them for 60min and mix them evenly, then put them into an alumina crucible;

[0069] (2) Put the uniformly mixed composite powder into the crucible, and react at 300°C for 48 hours under an inert atmosphere; after the reaction is completed, take out the reactant from the crucible;

[0070] (3) Wash the reaction product with deionized water: put the reaction product in a beaker, add deionized water, stir and ultrasonically clean for 10 minutes, then let sta...

Embodiment 3

[0073] In this embodiment, the composite material of subgroup metal composite MXenes is composed of metal Fe and Ti 3 C 2 Composition, Fe particles coated in situ on Ti 3 C 2 Surface and interlayer, whose chemical formula is Fe-Ti 3 C 2 , the Fe-Ti 3 C 2 The concrete preparation method of composite material is as follows:

[0074] (1) According to the precursor M n+1 AX n The molar ratio of phase material, subgroup metal salt and inorganic salt is 1:3:1.5 to weigh 1gTi 3 SiC 2 Powder, 2.1g FeCl 2 powder, 0.45g NaCl powder and 0.57g KCl powder, grind them for 50min and put them into an alumina crucible;

[0075] (2) Put the uniformly mixed composite powder into the crucible, and react at 500°C for 7 hours under an inert atmosphere; after the reaction is completed, take out the reactant from the crucible;

[0076] (3) Wash the reaction product with deionized water: put the reaction product in a beaker, add deionized water, stir and ultrasonically clean for 10 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com