Surface treatment process for aluminum lamp housing

A technology for surface treatment and lamps, which is applied in the direction of surface pretreatment, metal material coating process, and device for coating liquid on the surface, etc. It can solve the problem of affecting the use time of spray coating adhesion, high alkalinity of degreasing solution, and complicated production process. and other problems, to achieve the effect of less floor space, longer protection time and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

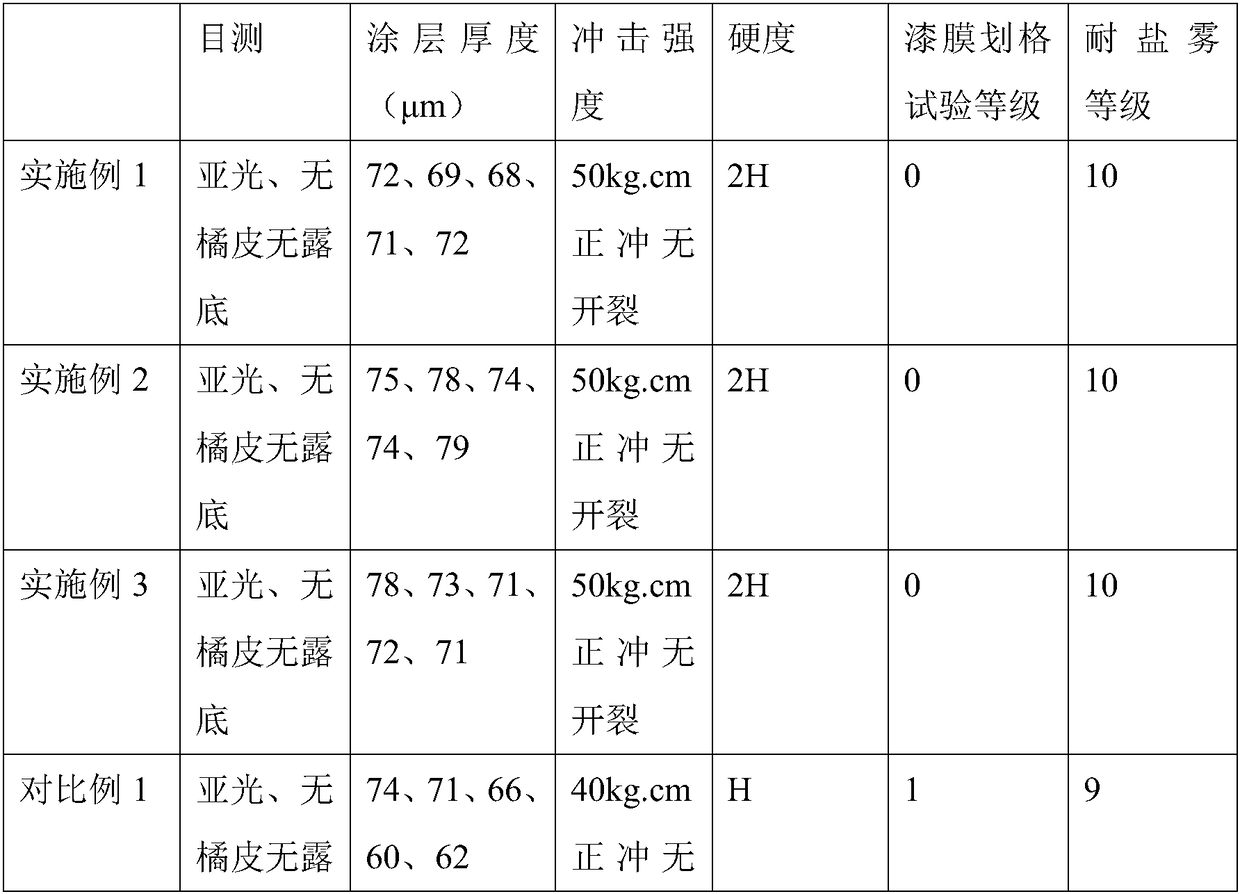

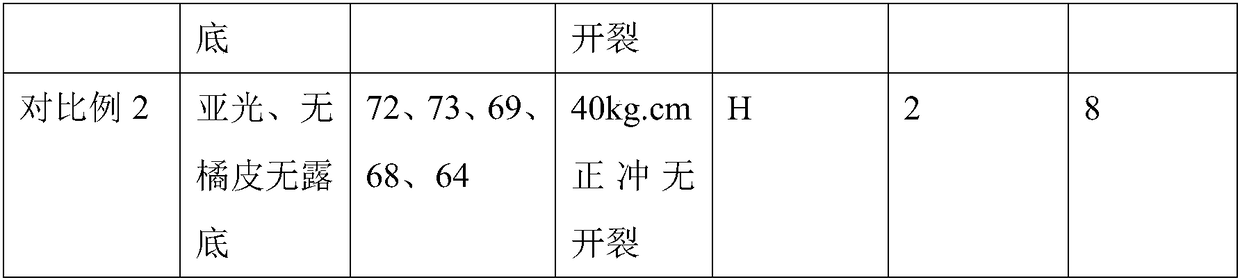

Embodiment 1

[0042] (1) Prepare the workpiece blank: the surface of the cast aluminum workpiece blank must be smooth, free of sticky sand, cold shut, air holes, pinholes, wrinkled skin and cracks; Removal of oil stains and welding oxides; no pit marks and bulges on the non-processed surface; no aluminum chips and sand in the screw holes.

[0043] (2) Hang the workpiece blank on the hanger of the plastic spraying line: the hook, hanger and workpiece blank should be grounded. The hooks and hangers can be put into a hot cleaning furnace for further use according to usage conditions.

[0044](3) Anti-coating operation: According to the workpiece and the number of wire holes that need anti-coating, the anti-coating work of the wire holes is carried out before cleaning.

[0045] (4) Hot water washing operation: at 40°C, use tap water to spray the workpiece for 2 minutes to remove ash and oil stains, and ensure that the bath overflows so that the oil on the bath surface can be discharged as much...

Embodiment 2

[0070] (1) Prepare the workpiece blank: the surface of the cast aluminum workpiece blank must be smooth, free of sticky sand, cold shut, air holes, pinholes, wrinkled skin and cracks; Oil stains and welding oxides are removed; the non-processed surface must be free of pit marks and bulges; there must be no aluminum chips and sand in the screw holes.

[0071] (2) Hang the workpiece blank on the hanger of the plastic spraying line: the hook, hanger and workpiece blank should be grounded. The hooks and hangers can be put into a hot cleaning furnace for further use according to usage conditions.

[0072] (3) Anti-coating operation: According to the workpiece and the number of wire holes that need anti-coating, the anti-coating work of the wire holes is carried out before cleaning.

[0073] (4) Hot water washing operation: at 50°C, use tap water to spray the workpiece for 1 minute to remove ash and oil stains. Ensure that the tank liquid overflows so that the oil on the tank liqui...

Embodiment 3

[0098] (1) Prepare the workpiece blank: the surface of the cast aluminum workpiece blank must be smooth, free of sticky sand, cold shut, air holes, pinholes, wrinkled skin and cracks; Removal of oil stains and welding oxides; no pit marks and bulges on the non-processed surface; no aluminum chips and sand in the screw holes.

[0099] (2) Hang the workpiece blank on the hanger of the plastic spraying line: the hook, hanger and workpiece blank should be grounded. The hooks and hangers can be put into a hot cleaning furnace for further use according to usage conditions.

[0100] (3) Anti-coating operation: According to the workpiece and the number of wire holes that need anti-coating, the anti-coating work of the wire holes is carried out before cleaning.

[0101] (4) Hot water washing operation: at a temperature of 45°C, use tap water to spray the workpiece for 1.5 minutes to remove ash and oil stains, and ensure that the bath overflows. So that the oil on the liquid surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com