A kind of semi-synthetic aluminum alloy processing fluid and preparation method thereof

An aluminum alloy and semi-synthetic technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of aggravating the anti-rust and corrosion performance of aluminum alloys, the attenuation of corrosion and anti-rust performance, and the increase in the hardness of processing fluids, so as to avoid oxidation Loss of light or even corrosion, long cycle life, high alkali reserve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned semi-synthetic aluminum alloy processing fluid comprises the following steps:

[0043] S1: Add the prescribed amount of deionized water, pH value stabilizer and corrosion inhibitor into the reaction kettle equipped with reflux condenser, stirrer and thermometer, stir to raise the temperature to 70°C, and continue to stir until completely dissolved;

[0044] S2: Stop heating, add base oil, organic synthetic ester, and emulsifier in a formulated amount to the solution system in step S1, and continue stirring until uniform;

[0045] S3: Stir continuously until the system cools down to room temperature, add the antibacterial agent and defoamer in the prescribed amount and stir evenly, and obtain the stock solution of the semi-synthetic aluminum alloy processing fluid.

Embodiment 1-5

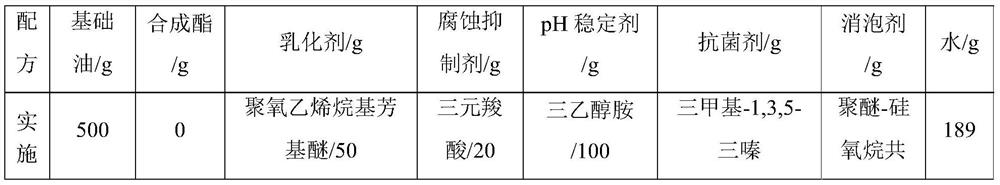

[0049] Table 1 Example 1-5 Processing Fluid Composition

[0050]

[0051]

[0052] The preparation method of the semi-synthetic aluminum alloy processing fluid of embodiment 1-5 all comprises the following steps:

[0053] S1: Add the prescribed amount of deionized water, pH value stabilizer and corrosion inhibitor into the reaction kettle equipped with reflux condenser, stirrer and thermometer, stir to raise the temperature to 70°C, and continue to stir until completely dissolved;

[0054] S2: Stop heating, add base oil, organic synthetic ester, and emulsifier in a formulated amount to the solution system in step S1, and continue stirring until uniform;

[0055] S3: Stir continuously until the system cools down to room temperature, add the antibacterial agent and defoamer in the prescribed amount and stir evenly, and obtain the stock solution of the semi-synthetic aluminum alloy processing fluid.

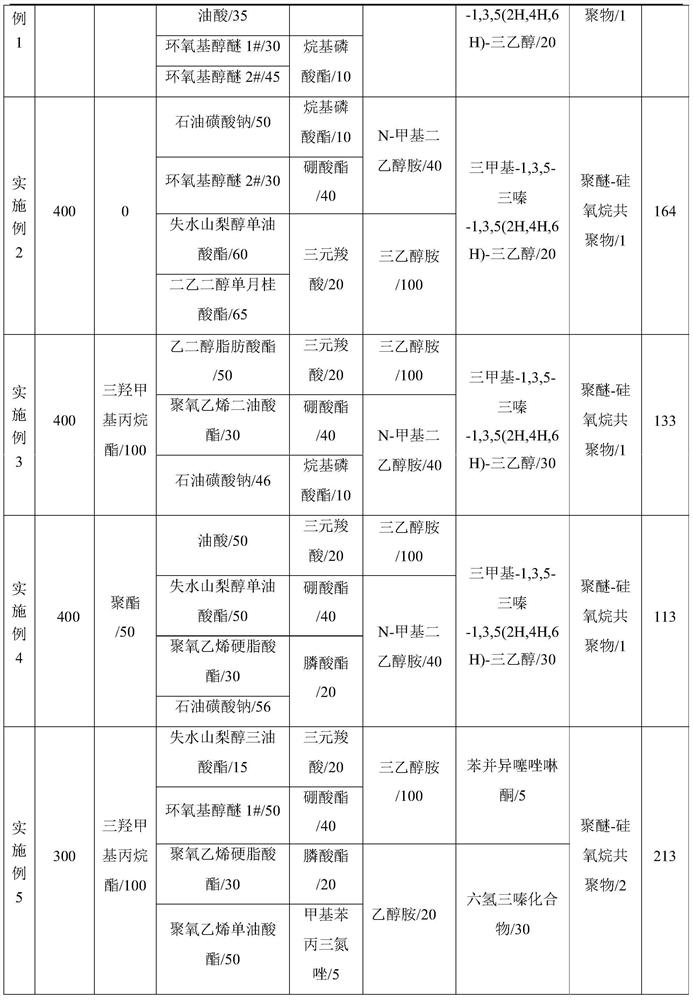

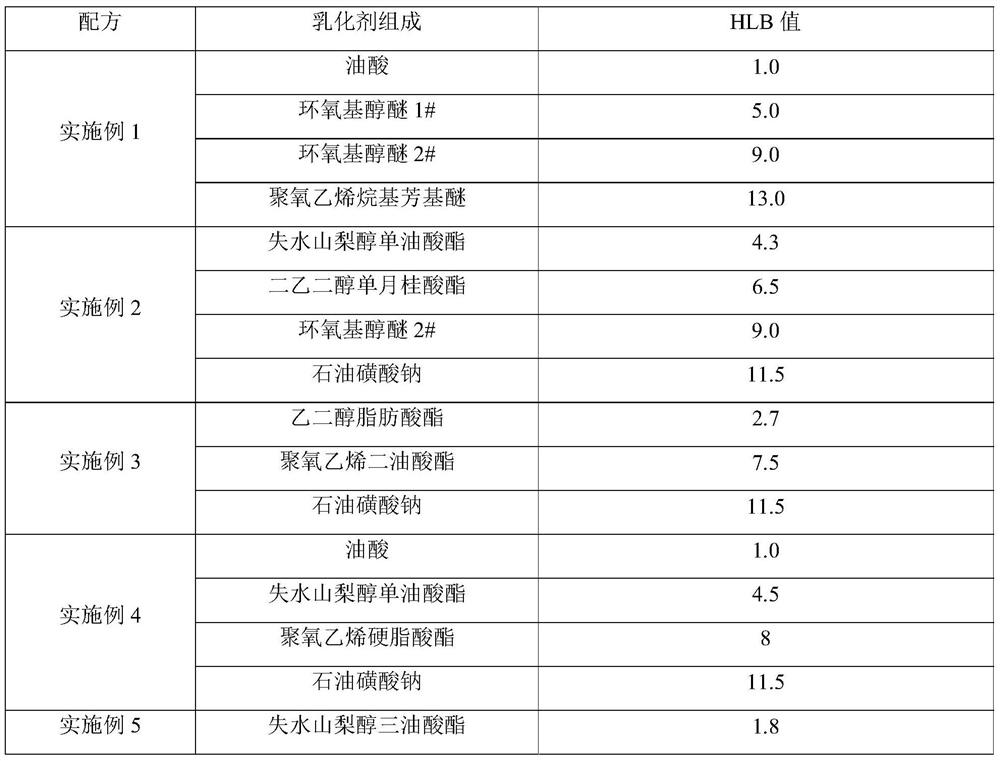

[0056] Among them, the emulsifier composition and HLB value distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com