Water-permeable brick with artificial carbonized steel slag pellets as aggregates and preparation method thereof

A carbonized steel slag and permeable brick technology, which is applied in the field of green building materials, can solve the problems of low water permeability, poor stability, and low steel slag content, and achieve high water permeability, qualified stability, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

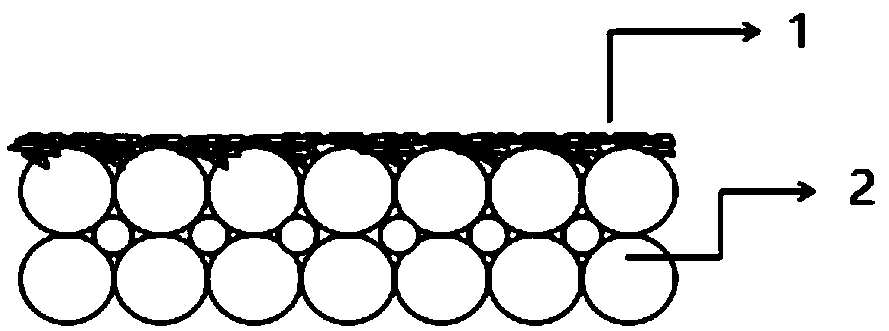

Image

Examples

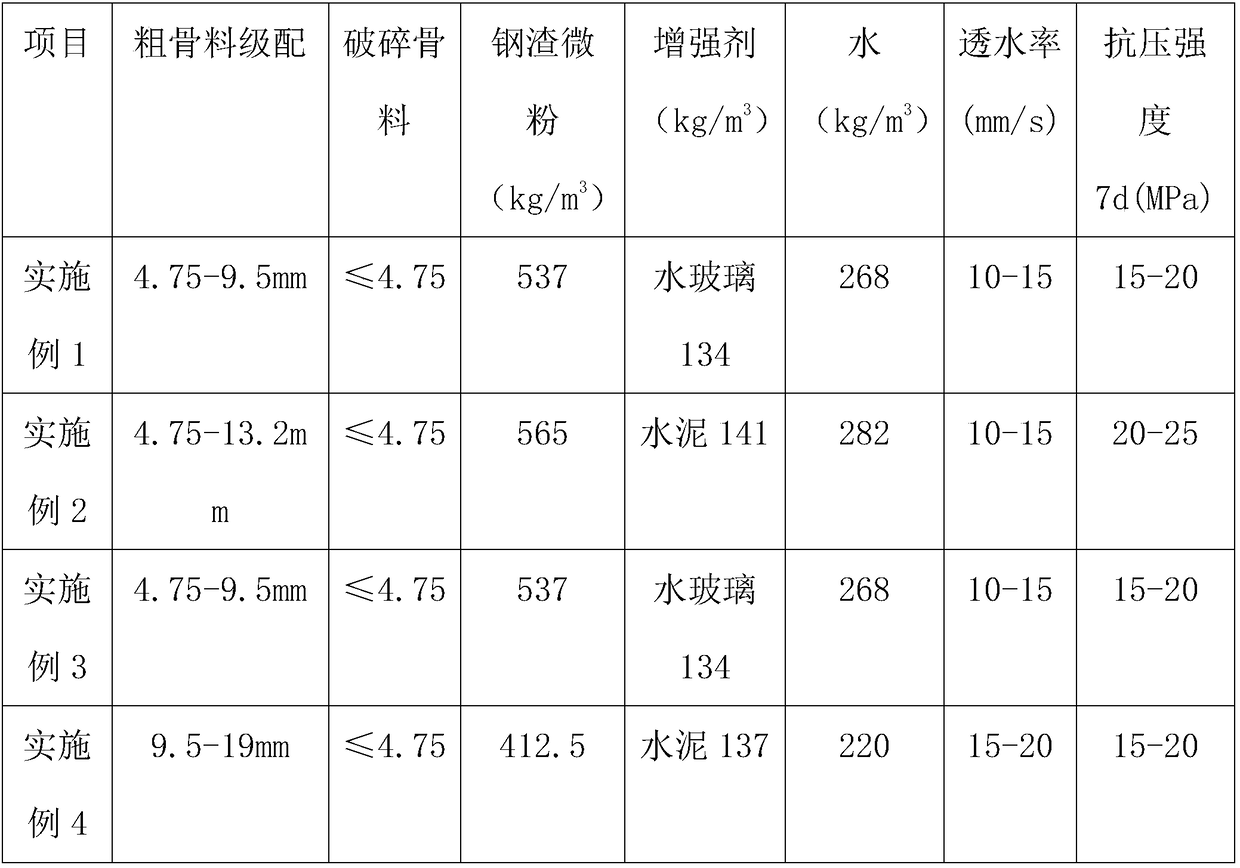

Embodiment 1

[0026] Embodiment 1: This embodiment provides a preparation process for permeable bricks with high steel slag content. Taking the configuration of 1 cubic meter of steel slag permeable concrete as an example, the preparation method is: mix 537kg steel slag powder, 134kg water glass, and 268kg water by Stir evenly to form a slurry, the second step: sieve out 1880kg of carbonized steel slag ball aggregates with a gradation of 4.75-9.5mm and put them into the filter screen, then immerse in the slurry to make the spheres fully hang the slurry, lift it up, filter out the excess slurry and pour it Flatten into the mould. Step 3: Put 268kg of broken carbonized steel slag brick ≤ 4.75mm fine aggregate into the filter screen, then immerse in the slurry to make the sphere fully coated with slurry, then lift it up, filter out the excess slurry and spread it on the ball aggregate structure in the mold Compact and level. Place the formed mold in an indoor ventilated environment for 24 hou...

Embodiment 2

[0029] Embodiment 2: Its preparation method is: 565kg steel slag powder, 141kg cement, 282kg water are evenly formed into a slurry by stirring, the second step: screen out 1980kg of carbide steel slag ball aggregates with a gradation of 4.75-13.2mm and put them in the filter screen , and then dipped into the slurry to make the sphere fully hang the slurry, then lift it up, filter out the excess slurry, pour it into the mold and spread it flat. Step 3: Put 282kg of fine aggregate of broken carbonized steel slag bricks ≤ 4.75mm into the filter screen, then immerse in the slurry to make the ball fully coated with slurry, then lift it up, filter out the excess slurry and spread it on the ball aggregate structure in the mold Compact and level. Place the formed mold in an indoor ventilated environment for 24 hours until the optimum moisture content of carbonization curing is placed in the carbonization kettle, and 99.9% pure CO is introduced 2 , the carbonization pressure is 0.3MPa...

Embodiment 3

[0030] Embodiment 3: Its preparation method is: 537kg steel slag powder, 134kg water glass, 268kg water are evenly formed into a slurry by stirring, the second step: screen out 1880kg of carbide steel slag ball aggregates with a gradation of 4.75-9.5mm and put them into a filter screen Then immerse in the slurry to make the sphere fully hang the slurry, then lift it up, filter out the excess slurry, pour it into the mold and pave it flat. Step 3: Put 268kg of broken carbonized steel slag brick ≤ 4.75mm fine aggregate into the filter screen, then immerse in the slurry to make the sphere fully coated with slurry, then lift it up, filter out the excess slurry and spread it on the ball aggregate structure in the mold Compact and level. Place the formed mold in an indoor ventilated environment for 24 hours until the optimum moisture content of carbonization curing is placed in the carbonization kettle, and 99.9% pure CO is introduced 2 , the carbonization pressure is 0.3MPa, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com