Steel and iron waste water treatment agent and method using same to treat waste water

A wastewater treatment agent and treatment method technology, applied in the direction of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., to achieve the effect of increasing the sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

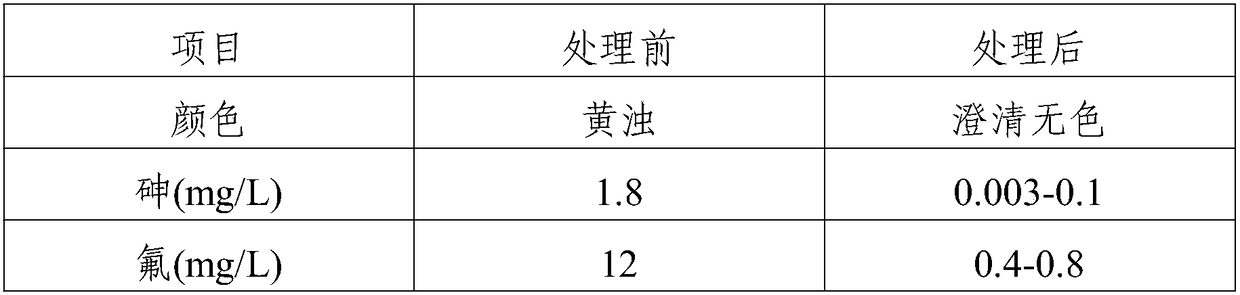

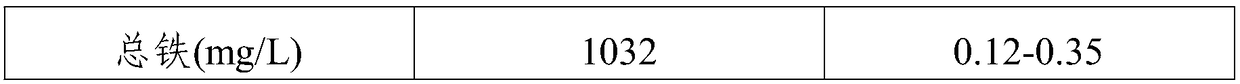

Examples

Embodiment 1

[0022] A steel wastewater treatment agent, the wastewater treatment agent is made of the following raw materials in parts by weight: 20 parts of polyacrylamide, 4 parts of ferrous sulfate, 12 parts of polyaluminium chloride, 4 parts of zeolite, 2 parts of cobalt acetate, alum 1 part of soil powder.

[0023] A treatment method for iron and steel wastewater, said treatment method comprising the following steps:

[0024] (1) Iron and steel wastewater pretreatment: the iron and steel wastewater is first passed through the coarse particle separator equipment to remove the suspended impurities of large particles, and then the wastewater except for large particles is passed into the sedimentation tank;

[0025] (2) Catalytic precipitation: add ferric hydroxide to the iron and steel wastewater in the sedimentation tank, then pass nitrogen monoxide into the tank for catalytic oxidation, let it stand for a period of time, filter and precipitate, and the wastewater continues to precipita...

Embodiment 2

[0030] A steel wastewater treatment agent, the wastewater treatment agent is made of the following raw materials in parts by weight: 30 parts of polyacrylamide, 6 parts of ferrous sulfate, 16 parts of polyaluminum chloride, 8 parts of zeolite, 4 parts of cobalt acetate, alum 2 parts of soil powder.

[0031] A treatment method for iron and steel wastewater, said treatment method comprising the following steps:

[0032] (1) Iron and steel wastewater pretreatment: the iron and steel wastewater is first passed through the coarse particle separator equipment to remove the suspended impurities of large particles, and then the wastewater except for large particles is passed into the sedimentation tank;

[0033] (2) Catalytic precipitation: add ferric hydroxide to the iron and steel wastewater in the sedimentation tank, then pass nitrogen monoxide into the tank for catalytic oxidation, let it stand for a period of time, filter and precipitate, and the wastewater continues to precipita...

Embodiment 3

[0038] A steel wastewater treatment agent, the wastewater treatment agent is made of the following raw materials in parts by weight: 25 parts of polyacrylamide, 5 parts of ferrous sulfate, 14 parts of polyaluminum chloride, 6 parts of zeolite, 3 parts of cobalt acetate, alum 1.5 parts of soil powder.

[0039] A treatment method for iron and steel wastewater, said treatment method comprising the following steps:

[0040] (1) Iron and steel wastewater pretreatment: the iron and steel wastewater is first passed through the coarse particle separator equipment to remove the suspended impurities of large particles, and then the wastewater except for large particles is passed into the sedimentation tank;

[0041] (2) Catalytic precipitation: add ferric hydroxide to the iron and steel wastewater in the sedimentation tank, then pass nitrogen monoxide into the tank for catalytic oxidation, let it stand for a period of time, filter and precipitate, and the wastewater continues to precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com