Preparation method of water-resistant easily-degradable plastic toy

A technology for easily degradable plastics and toys, which is applied in the field of plastic toy preparation, can solve the problems of plastic toys such as discoloration, molecular chain breakage, and poor water resistance, so as to achieve the advantages of no shortened service life, lower glass transition temperature, and excellent corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

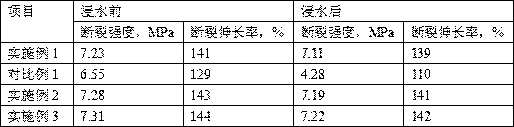

Examples

Embodiment 1

[0018] A method for preparing a water-resistant and easily degradable plastic toy, comprising the following steps:

[0019] (1) In parts by weight, add 5 parts of lanthanum chloride and 7 parts of gadolinium chloride to 60 parts of water, then add 19 parts of naphthenic acid to it, mix and stir evenly, then raise the temperature of the mixture to 80°C Finally, keep warm for 2 hours, then cool to room temperature, continue to add 15 parts of polyethanolamine to it, after mixing and stirring evenly, the starch modifier is obtained;

[0020] (2) In parts by weight, 55 parts of starch and 3 parts of starch modifier are added to the internal mixer, and after mixing, thermoplastic starch is obtained;

[0021] (3) In parts by weight, add 88 parts of thermoplastic starch, 44 parts of polylactic acid, 0.1 part of antioxidant, and 1 part of plasticizer into a high-speed mixer. After mixing evenly, use a twin-screw extruder to extrude After cooling, drying, and pelletizing to obtain pla...

Embodiment 2

[0028] A method for preparing a water-resistant and easily degradable plastic toy, comprising the following steps:

[0029] (1) In parts by weight, add 7 parts of lanthanum chloride and 9 parts of gadolinium chloride to 65 parts of water, then add 23 parts of naphthenic acid to it, mix and stir evenly, and raise the temperature of the mixture to 84°C Finally, keep warm for 2.5 hours, then cool to room temperature, continue to add 18 parts of polyethanolamine to it, after mixing and stirring evenly, the starch modifier is obtained;

[0030] (2) In parts by weight, 58 parts of starch and 3 parts of starch modifier are added to the internal mixer, and after mixing, thermoplastic starch is obtained;

[0031] (3) In parts by weight, add 90 parts of thermoplastic starch, 48 parts of polylactic acid, 0.3 parts of antioxidant, and 3 parts of plasticizer into a high-speed mixer. After mixing evenly, use a twin-screw extruder to extrude After cooling, drying, and pelletizing to obtain ...

Embodiment 3

[0038] A method for preparing a water-resistant and easily degradable plastic toy, comprising the following steps:

[0039] (1) In parts by weight, add 8 parts of lanthanum chloride and 11 parts of gadolinium chloride to 70 parts of water, then add 25 parts of naphthenic acid to it, mix and stir evenly, and raise the temperature of the mixture to 88°C Finally, keep warm for 3 hours, then cool to room temperature, continue to add 20 parts of polyethanolamine to it, after mixing and stirring evenly, the starch modifier is obtained;

[0040] (2) In parts by weight, 60 parts of starch and 4 parts of starch modifier are added to the internal mixer, and after mixing, thermoplastic starch is obtained;

[0041] (3) In parts by weight, add 92 parts of thermoplastic starch, 50 parts of polylactic acid, 0.5 parts of antioxidant, and 4 parts of plasticizer into a high-speed mixer. After mixing evenly, use a twin-screw extruder to extrude After cooling, drying, and pelletizing to obtain p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com