Method and device for preparing hexafluoropropylene oxide oligomer

A technology of hexafluoropropylene oxide and oligomers, which is applied in the field of preparation of hexafluoropropylene oxide oligomers, and can solve the problems of low product yield and inability to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

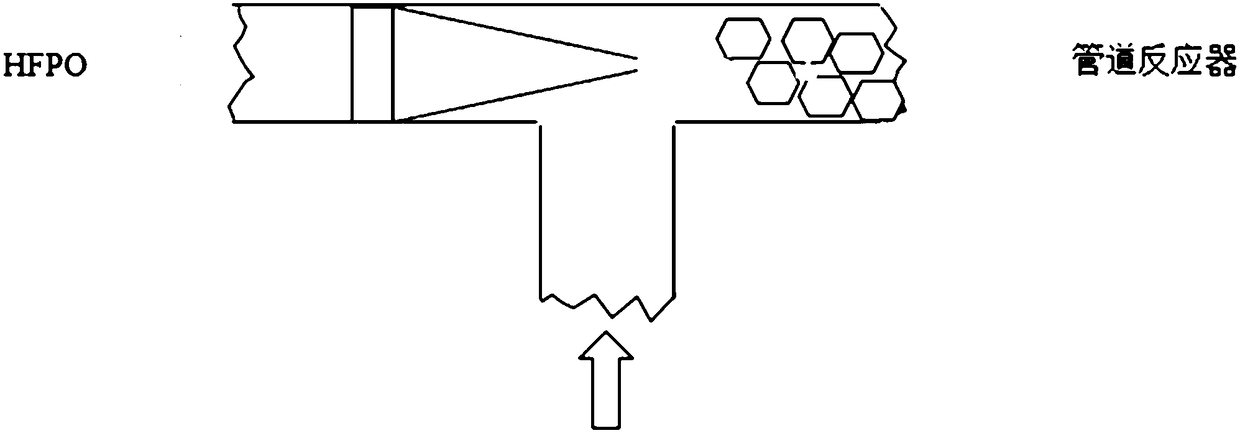

Image

Examples

Embodiment 1

[0057] Under nitrogen protection, 2.0g of potassium fluoride, 600g of diethylene glycol dimethyl ether, 50.0g of N,N,N',N',-tetramethylethylenediamine, 2.0g of triethylamine and The catalyst system solution composed of 2.0g of water is moved into the tubular reactor, and the catalyst solution is started to circulate in the tubular reactor through a diaphragm metering pump. The flow rate of the catalyst solution is 6L / h, and the temperature of the cooling tank is controlled. to 5°C, replace the air in the reaction device, and apply an initial pressure of 0.1MPa with nitrogen; when no bubbles are observed in the pipeline reactor and the temperature of the catalyst solution remains stable, HFPO is continuously introduced at a certain rate to adjust the pressure of HFPO in the pipeline. The dwell time is 8s. In the early stage of the reaction, the pressure rose slowly to 0.3MPa, and when there were no bubbles at the outlet of the pipeline, the pressure began to remain stable. At ...

Embodiment 2

[0060] Under nitrogen protection, 2.0g of potassium fluoride, 600g of diethylene glycol dimethyl ether, 50.0g of N,N,N',N',-tetramethylethylenediamine, 2.0g of triethylamine and The catalyst system solution that the water of 2.0g forms is moved in the tubular reaction device, and the catalyst solution is started to circulate in the tubular reactor by a diaphragm metering pump, the catalyst flow rate is 6L / h, and the temperature of the cooling tank is controlled to be 5°C, replace the air in the reaction device, and apply an initial pressure of 0.1MPa with nitrogen; when no bubbles are observed in the pipeline reactor and the temperature of the catalyst solution remains stable, continue to feed HFPO at a certain rate to adjust the stay of HFPO in the pipeline The time is 4s. In the early stage of the reaction, the pressure rose slowly to 0.5MPa, and when there were no bubbles at the outlet of the pipeline, the pressure began to remain stable. At this time, transparent crude pr...

Embodiment 3

[0063] Under nitrogen protection, 2.0g of potassium fluoride, 600g of diethylene glycol dimethyl ether, 50.0g of N,N,N',N',-tetramethylethylenediamine, 2.0g of triethylamine and The catalyst system solution composed of 2.0g of hydrofluoric acid is moved into the tubular reactor, and the catalyst solution is started to circulate in the tubular reactor through a diaphragm metering pump. The flow rate of the catalyst solution is 6L / h and the cooling tank is controlled The temperature is 5°C, the air in the reaction device is replaced, and the initial pressure of 0.1MPa is applied by nitrogen; when no bubbles are observed in the pipeline reactor and the temperature of the catalyst solution remains stable, HFPO is continuously introduced at a certain rate to adjust the flow of HFPO in the pipeline. The residence time is 8s. In the early stage of the reaction, the pressure rose slowly to 0.35MPa, and when there were no bubbles at the outlet of the pipeline, the pressure began to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com