Concrete sand washing experiment apparatus for off-center shaft type irrigation work

A technology of hydraulic concrete and eccentric shaft, which is applied in the direction of instruments, scientific instruments, and testing wear resistance, etc. It can solve the problems of fixed speed, poor instrument performance, and inability to simulate water flow speed, etc., and achieves the effect of simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with specific examples, but the structure of the present invention is not limited to the following examples.

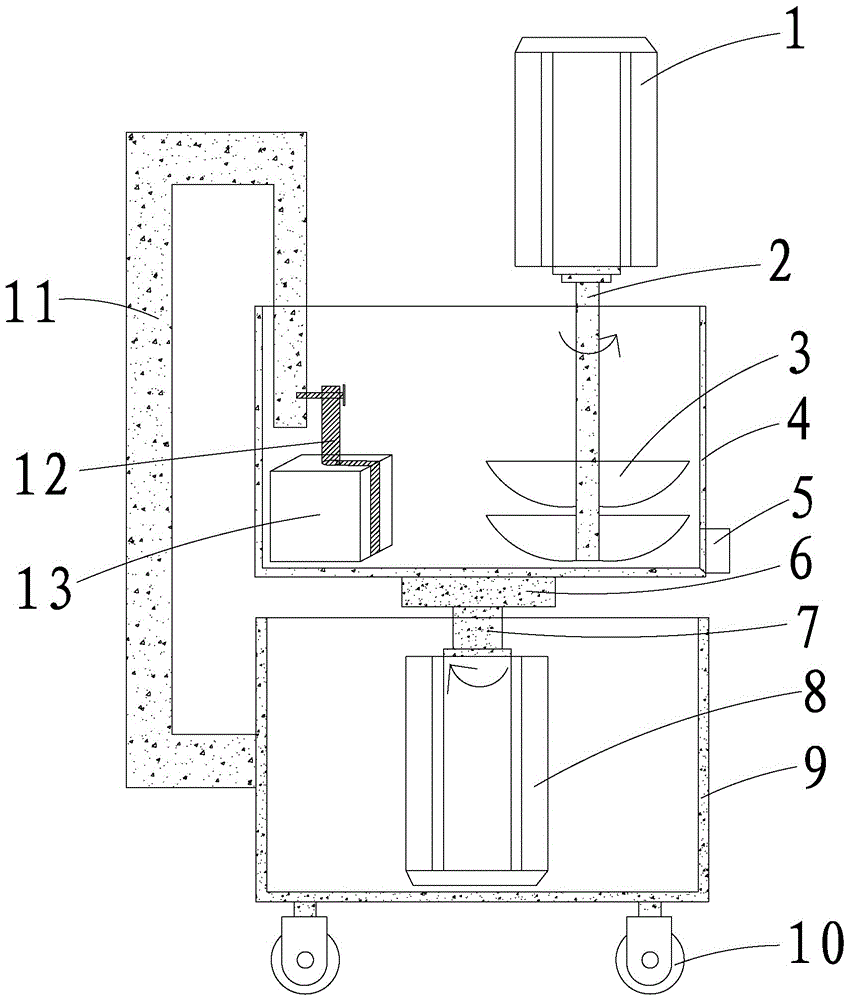

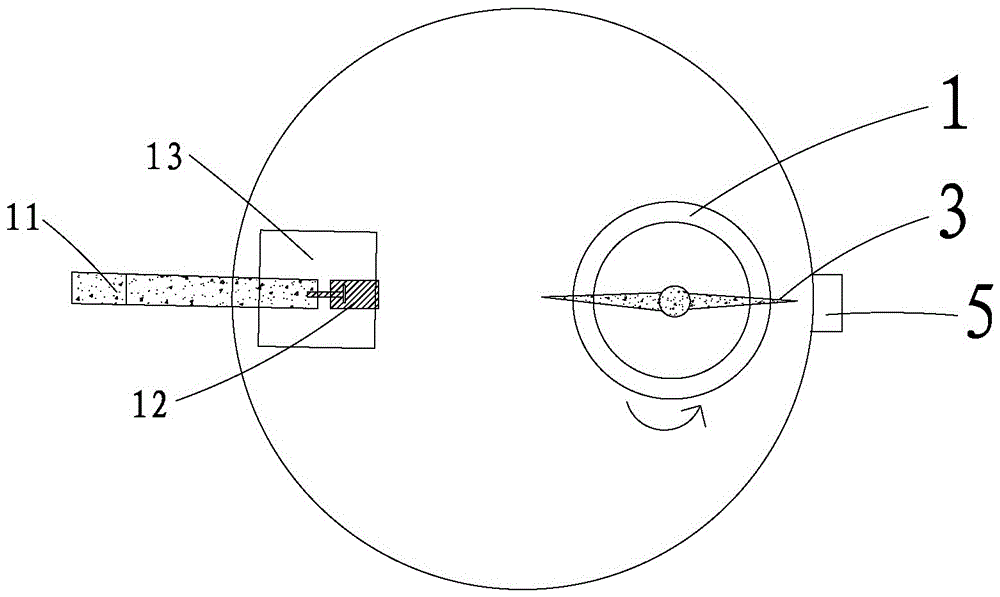

[0016] see figure 1 and figure 2 As shown, a kind of eccentric shaft type hydraulic concrete water-sand grinding tester of the present invention comprises a first adjustable frequency conversion motor 1, a stirring shaft 2, at least one stirring blade 3, a stirring pot 4, a discharge Port 5, a stirring pot base 6, a rotating shaft 7, a second adjustable frequency conversion motor 8, a fixed base 9, at least two wheels 10, a connecting rod 11 and at least one specimen fixing clamp 12;

[0017] The stirring shaft 2 is installed in the stirring pot 4, the first adjustable frequency conversion motor 1 is fixed on the upper end of the stirring shaft 2, the stirring blade 3 is fixed on the lower end of the stirring shaft 2, The first adjustable frequency conversion motor 1 drives the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com