Equipment and method for preparing supercapacitor material through mesophase pitch

A technology of mesophase pitch, supercapacitor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

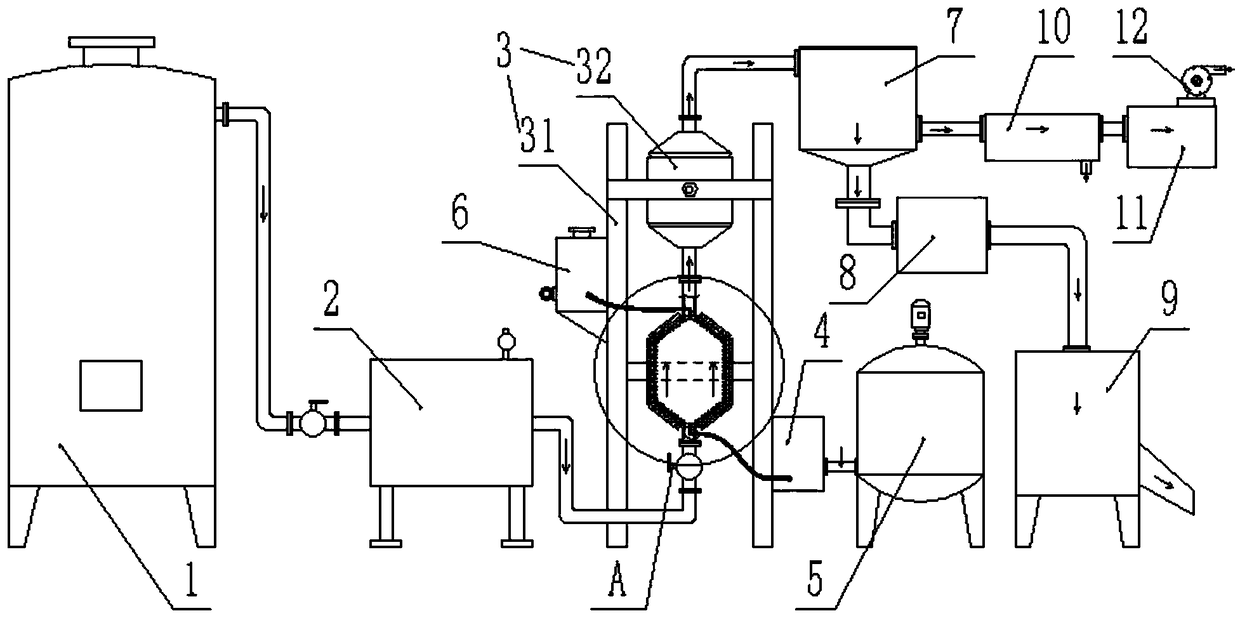

[0035] A kind of preparation method of the equipment of mesophase pitch preparation supercapacitor electrode material, its steps are as follows:

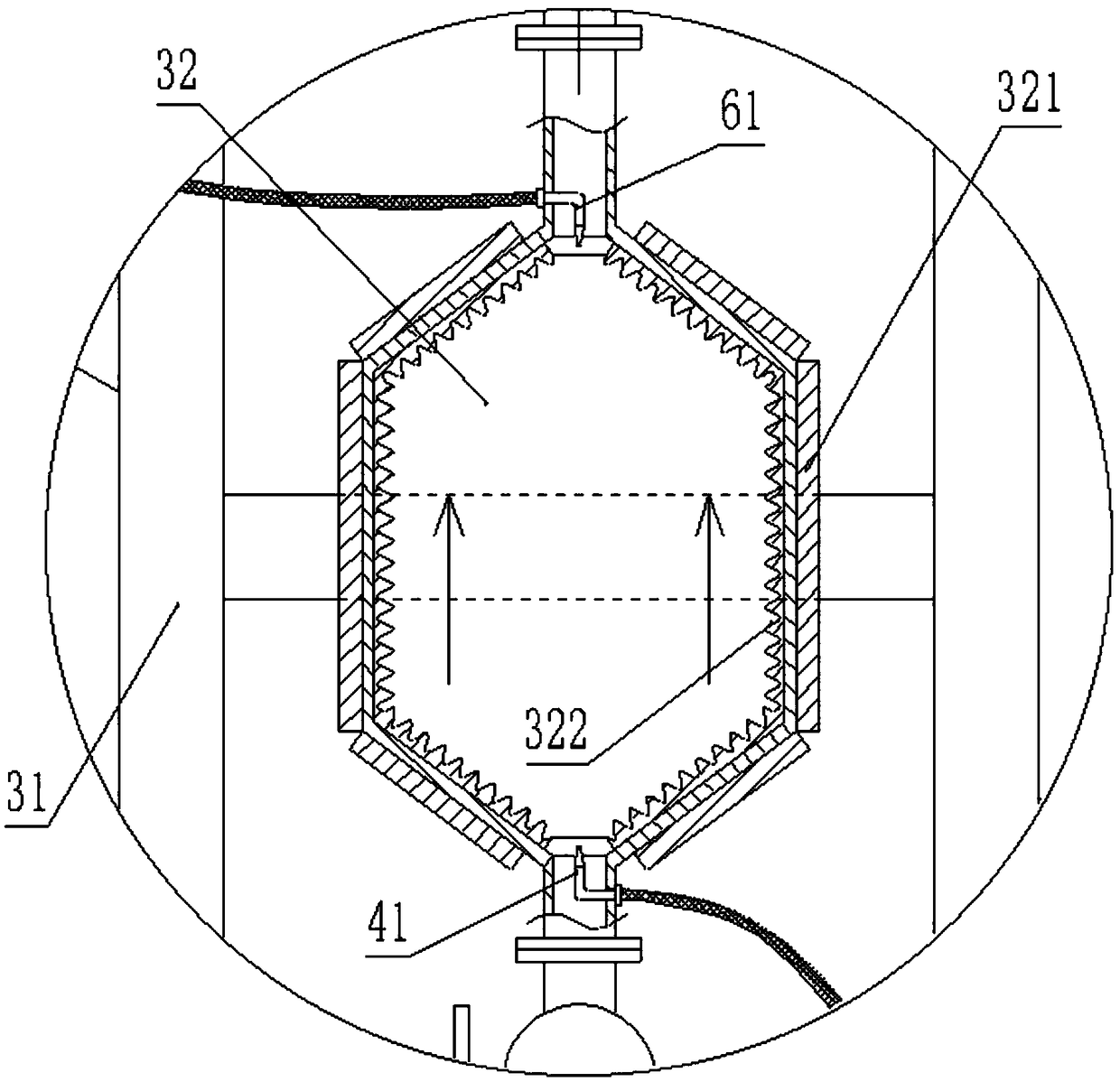

[0036] Step A: Heat the water vapor generated by the water steam generator through the air heater into superheated steam at a temperature of 950°C-1200°C, adjust the output pressure of the air heater to 4-20bar, and send it to the activation heating device ;

[0037] Step B: Select a mesophase pitch raw material with a softening point of 120°C-260°C and an average molecular weight of 800-1600. This raw material has low viscosity, good fluidity, and high carbon yield, and heats it through the reactor to 150-200 ℃, after heating and melting, it is sprayed into the activation heating device through an ultrasonic atomizer;

[0038] Step C: The potassium hydroxide powder with a particle size of 200-500 mesh is sent into the activation heating device through a powder injector, and the potassium hydroxide powder and the mesophase pitch ar...

Embodiment 1

[0045] The water vapor generated by the steam generator is heated by the air heater to become superheated steam at a temperature of 950°C, the output pressure of the air heater is adjusted to 4bar, and sent to the activation heating device; the softening point is selected as 200°C, The mesophase pitch raw material with an average molecular weight of 800 is heated to 200°C through a reaction kettle, and after heating and melting, it is sprayed into an activation heating device through an ultrasonic atomizer; potassium hydroxide powder with a particle size of 300 mesh is sprayed The feeder is sent into the activation heating device, the potassium hydroxide powder and the mesophase pitch are sprayed against each other, and the mixture is fully mixed. The potassium hydroxide and the mesophase pitch are fully carbonized and activated in the heating section, and the mass ratio is 4:1. The time is 2s; the mixture of porous carbon and potassium hydroxide after the activation reaction i...

Embodiment 2

[0048] The water vapor generated by the steam generator is heated by the air heater to become superheated steam at a temperature of 950°C, the output pressure of the air heater is adjusted to 4bar, and sent to the activation heating device; the softening point is selected as 200°C, The mesophase pitch raw material with an average molecular weight of 800 is heated to 200°C through a reaction kettle, and after heating and melting, it is sprayed into an activation heating device through an ultrasonic atomizer; potassium hydroxide powder with a particle size of 300 mesh is sprayed The feeder is sent to the activation heating device, the potassium hydroxide powder and the mesophase pitch are sprayed against each other, and the mixture is fully mixed. The potassium hydroxide and the mesophase pitch are fully carbonized and activated in the heating section, and the mass ratio is 6 to 1. The reaction The time is 2s; the mixture of porous carbon and potassium hydroxide after the activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com