A gantry type grinding device

A grinding device, gantry-type technology, applied in the direction of grinding drive device, grinding machine, grinding workpiece support, etc., can solve the problems of poor grinding stability, tool precision and flatness, etc., to improve grinding precision, improve precision, ensure omnidirectional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

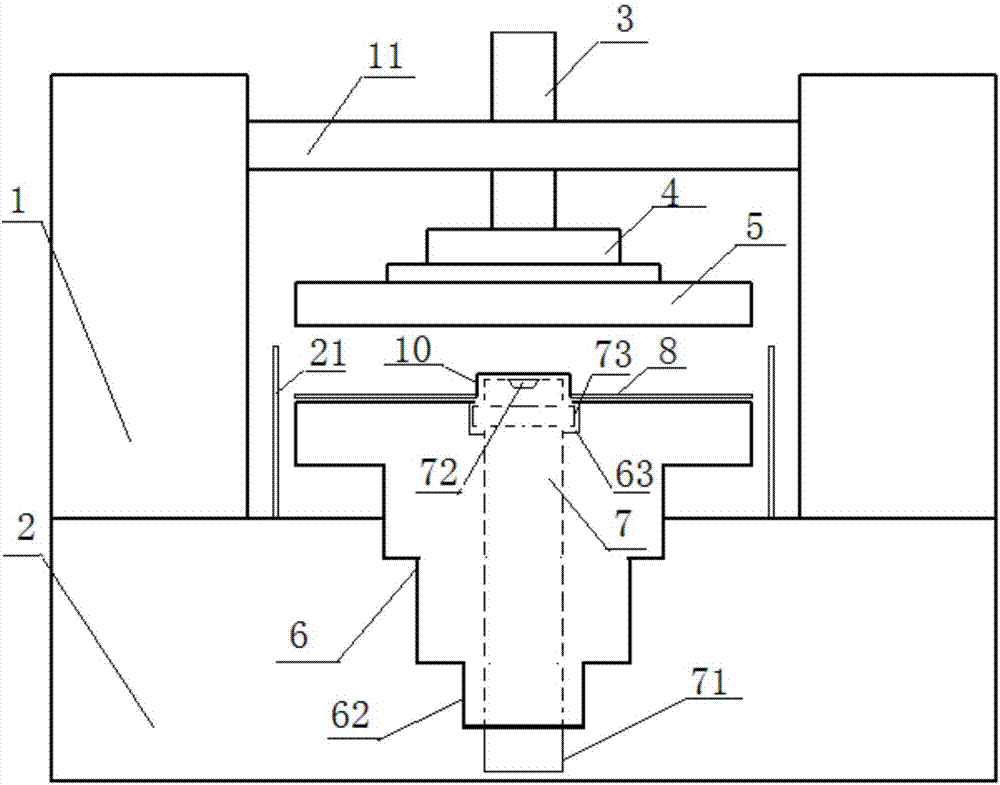

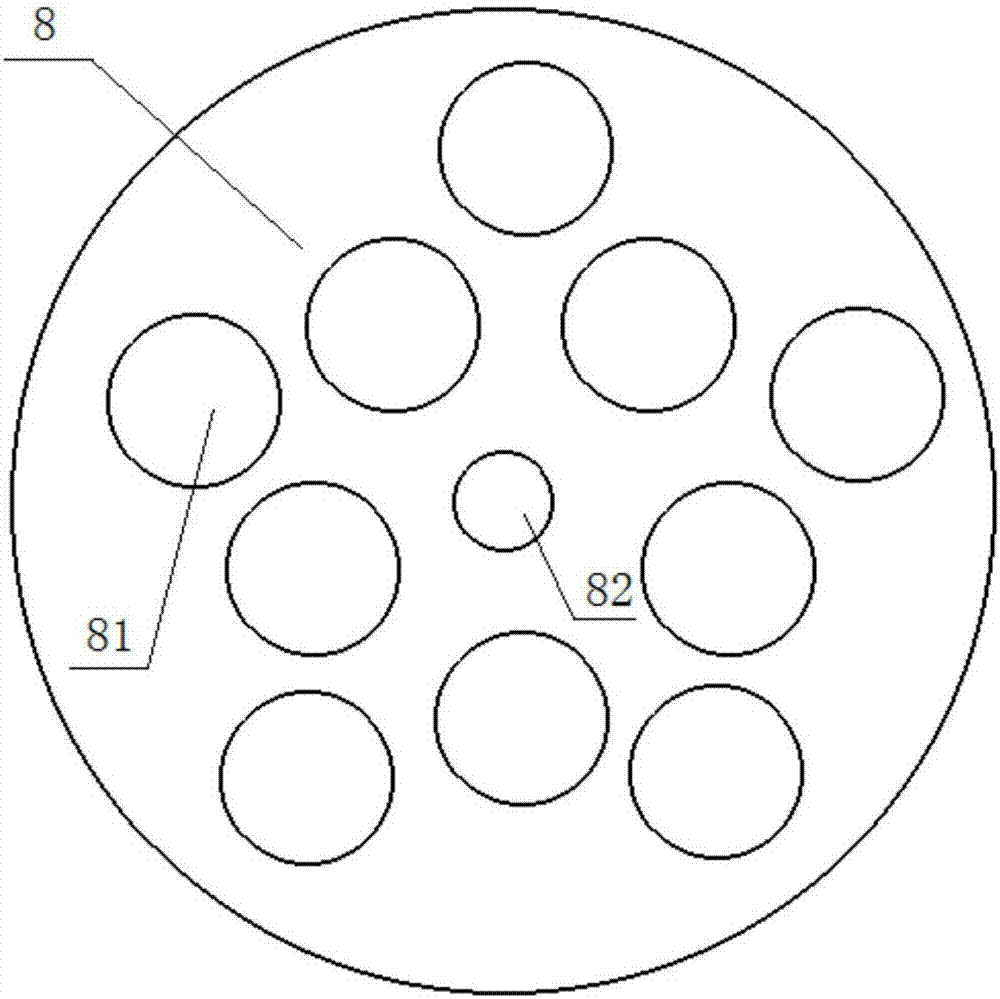

[0040] A kind of gantry grinding device of the present embodiment, such as figure 1 As shown, it includes an upper grinding disc 5 and a lower grinding disc 6 that are set up and down on the grinding surface, and also includes a gantry frame 1, a central shaft 7 and a mold 8, wherein: the upper grinding disc 5 is placed under the gantry beam 11 of the gantry frame 1 through a hydraulic rod 3 Reciprocate vertically up and down; the middle part of the lower millstone 6 has a vertical cavity through which the central axis 7 is inserted; Such as figure 2 As shown, the mold 8 is evenly distributed with 10 tool locking holes 81 with a diameter of 300mm. The lower grinding disc 6 and the central shaft 7 are all driven by the pulley to rotate, and the two are the same driving wheel, but the diameter of the driven wheel is different; the thickness of the mold 8 is less than the thickness of the tool to be processed.

[0041] The method that the gantry type grinding device of the pre...

Embodiment 2

[0050] Similar to Embodiment 1, the improvement is that: the pillars on both sides of the gantry 1 are vertically fixed on the upper surface of the platform 2; the compression rod of the hydraulic rod 3 passes through the gantry beam 11 and is fixedly connected to the upper grinding table 5; the central shaft 7 drives the mold 8 Eccentric rotation. The rotating speed of lower millstone 6 is greater than the rotating speed of mold 8. A grinding liquid cavity is arranged inside the upper grinding disc 5, and grinding liquid spraying holes are uniformly arranged on the lower surface, so that the grinding liquid can be sprayed continuously and more evenly. The rotational speed of the central shaft 7 is 20% of the rotational speed of the lower grinding disc 6 .

[0051] The method that the gantry type grinding device of the present embodiment produces the high-speed steel cutting tool, its steps are:

[0052] A. Fill 10 pieces of cutting tools with a diameter of 200 mm into the c...

Embodiment 3

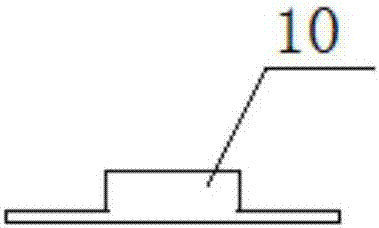

[0059] Similar to Embodiment 2, the improvement is: it also includes 2 stabilizing sleeves 4 and eccentric pin 9, protective cover 10, and is arranged on the periphery of the lower grinding disc 6, the grinding liquid pool 21 on the upper surface of the platform 2; the stabilizing sleeve 4 is Concentric with the upper grinding disc 5, fixed on the upper surface of the upper grinding disc 5, the compression rod of the hydraulic rod 3 passes through the stabilizing sleeve 4. After the two stabilizing sleeves 4 are fixedly connected, they are stacked on the upper grinding disc 5 in a stepped shape with a small upper part and a larger lower part. surface. The upper part of the cavity of the lower grinding disc 6 is a stepped hole 63, and the upper part of the central shaft 7 is provided with an annular protrusion 73. The diameter of the annular protrusion 73 is slightly smaller than the diameter of the stepped hole 63, and is embedded in the stepped hole 63 to stabilize the rotatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com