Semi-automatic natural gas pipeline sanding and polishing device

A natural gas pipeline and semi-automatic technology, used in grinding/polishing safety devices, grinding/polishing equipment, grinding machines, etc., can solve the problems of high labor cost and labor intensity of workers, improve production efficiency and save dust deposition time, convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

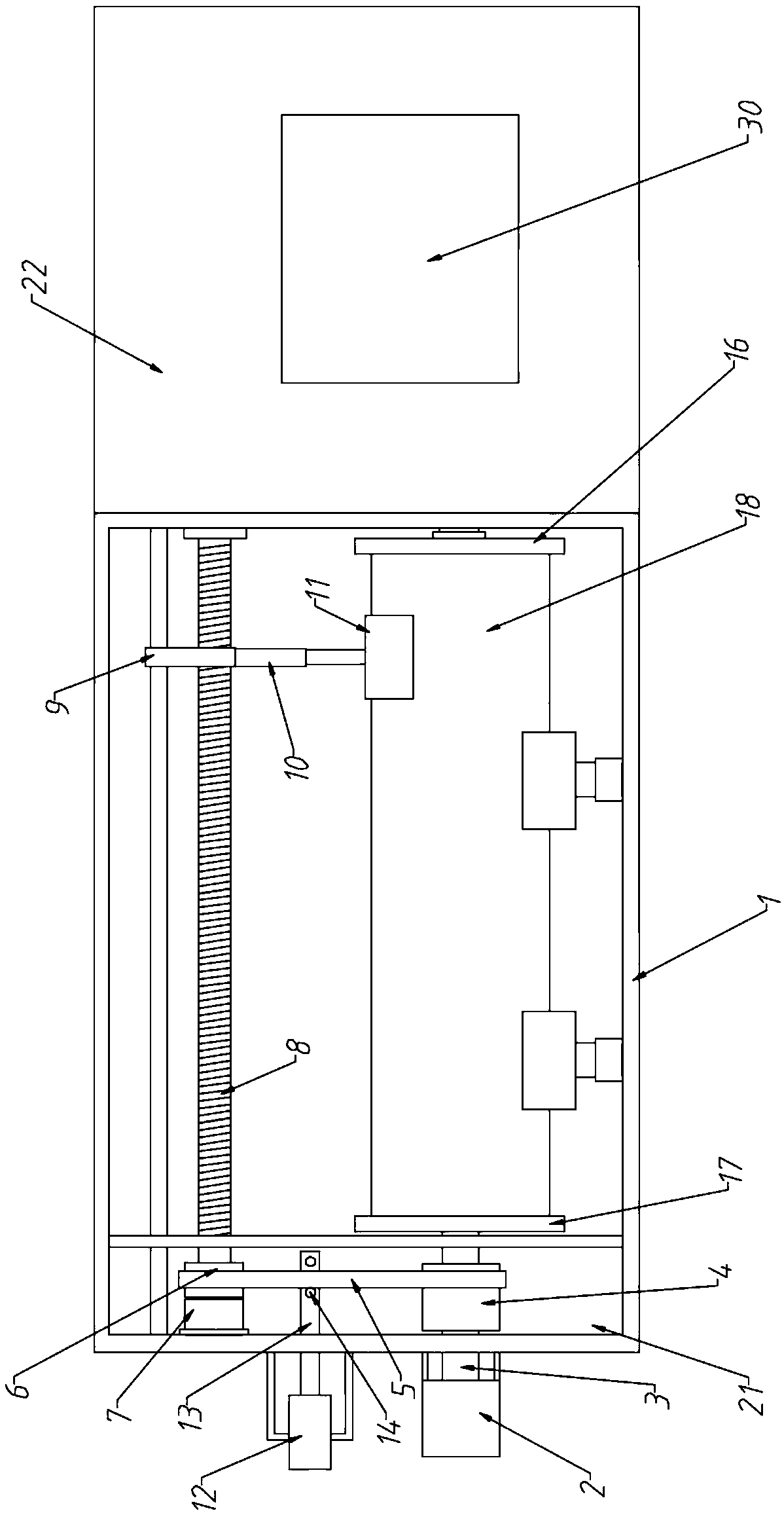

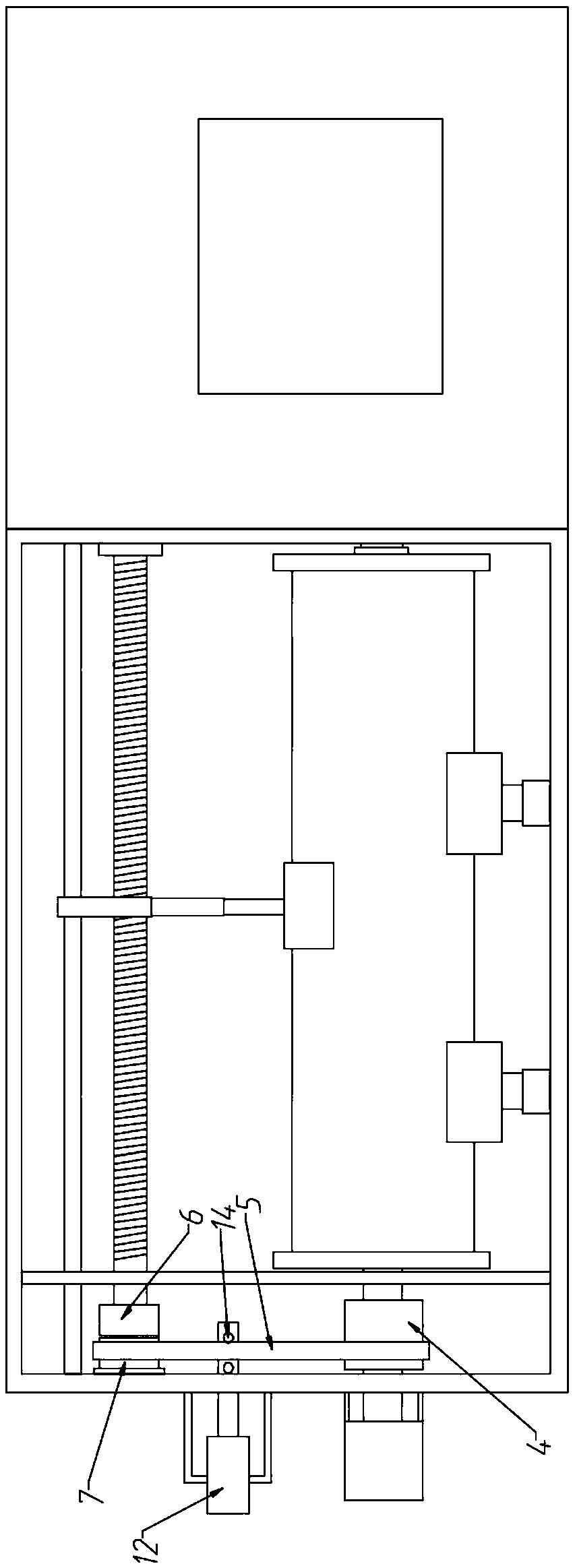

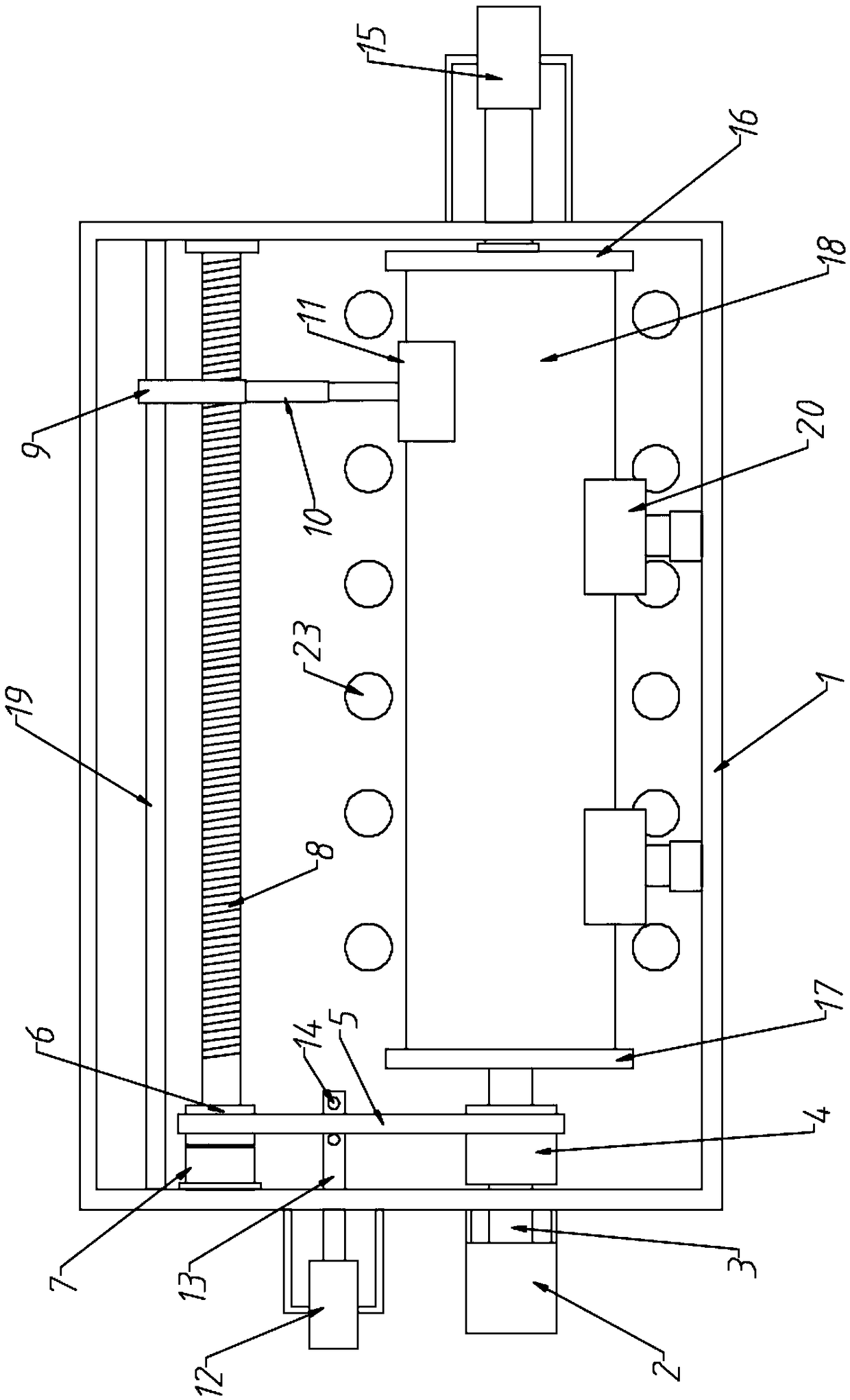

[0046] A semi-automatic grinding and polishing device for natural gas pipelines, including a grinding chamber 1, a grinding assembly and a clutch assembly;

[0047] The front side of the grinding chamber 1 is provided with a sliding door 22, and the left side is provided with a rotating motor 2. The rotating motor 2 stretches out the driving shaft 3 to the right, and the driving shaft 3 stretches into the grinding chamber 1 and is fixedly connected with a left turntable 17; 1 The right side is correspondingly provided with a No. 2 cylinder 15, and the telescopic rod of the No. 2 cylinder 15 extends into the grinding chamber 1 to the left and is connected with a right turntable 16 for rotation;

[0048] The grinding assembly includes a screw mandrel 8, an electric telescopic rod 10 and a grinding sleeve 11. The screw mandrel 8 is arranged on the upper part of the grinding chamber 1. The right end of the screw mandrel 8 is connected to the inner wall of the grinding chamber 1 thr...

Embodiment 2

[0053] The difference from Embodiment 1 is that the grinding sleeve 11 is an arc-shaped piece, and the top surface is provided with a protrusion 24, and the protrusion 24 is provided with a through groove connecting the bottom surface, and the grinding plate 25 is inserted and passed through the through groove, and the protrusion 24 Correspondingly, a locking screw 26 is provided, and the locking screw 26 fixes the grinding plate 25 on the grinding sleeve 11, so that the grinding plate 25 is mounted on the grinding sleeve 11 in a detachable and adjustable manner, so that the grinding plate 25 can be efficiently utilized. It is also easy to replace.

Embodiment 3

[0055] The difference from Embodiment 2 is that the bottom of the grinding chamber 1 is evenly provided with a support 20, the support 20 includes an arc-shaped support plate, a hydraulic rod 28 and a roller 27, and the hydraulic rod 28 is fixedly installed on the bottom of the grinding chamber 1. The support plate is arranged on the top of the hydraulic rod 28, and the top surface of the curved support plate is symmetrically provided with rollers 27, so that when the pipeline 18 is placed, the pipeline 18 can be mounted on the support member 20 first, and the height can be adjusted to the same height as the hydraulic rod 28. The left and right turntables 16 are coaxial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com