Full-automatic outfitting part airless spraying equipment robot

An airless spraying and outfitting technology, which is applied in the direction of spraying devices, etc., can solve the problems of construction personnel's health hazards, difficulty in precise control, and increased shipbuilding costs, etc., to achieve good gloss, uniform paint coating, and improve production The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

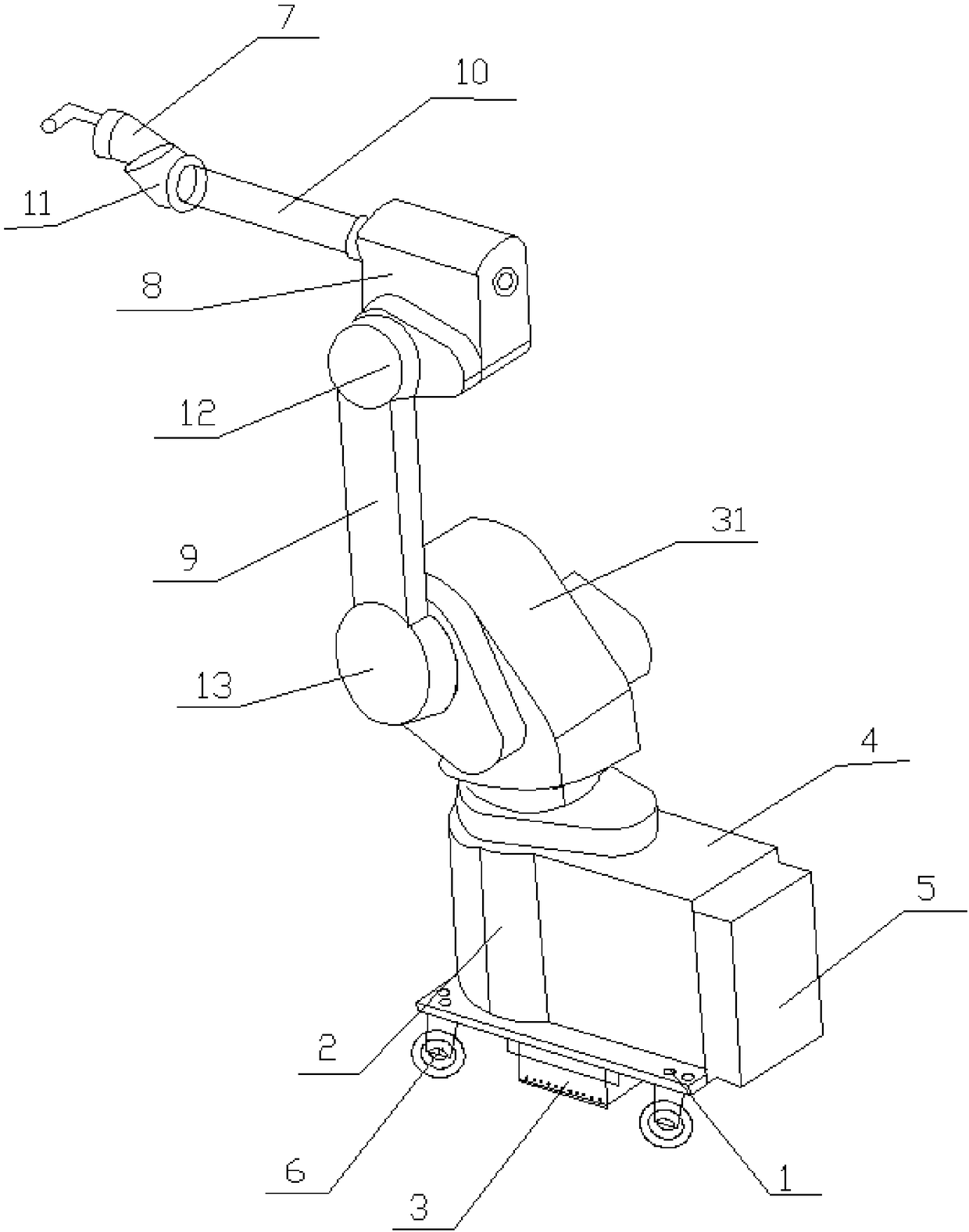

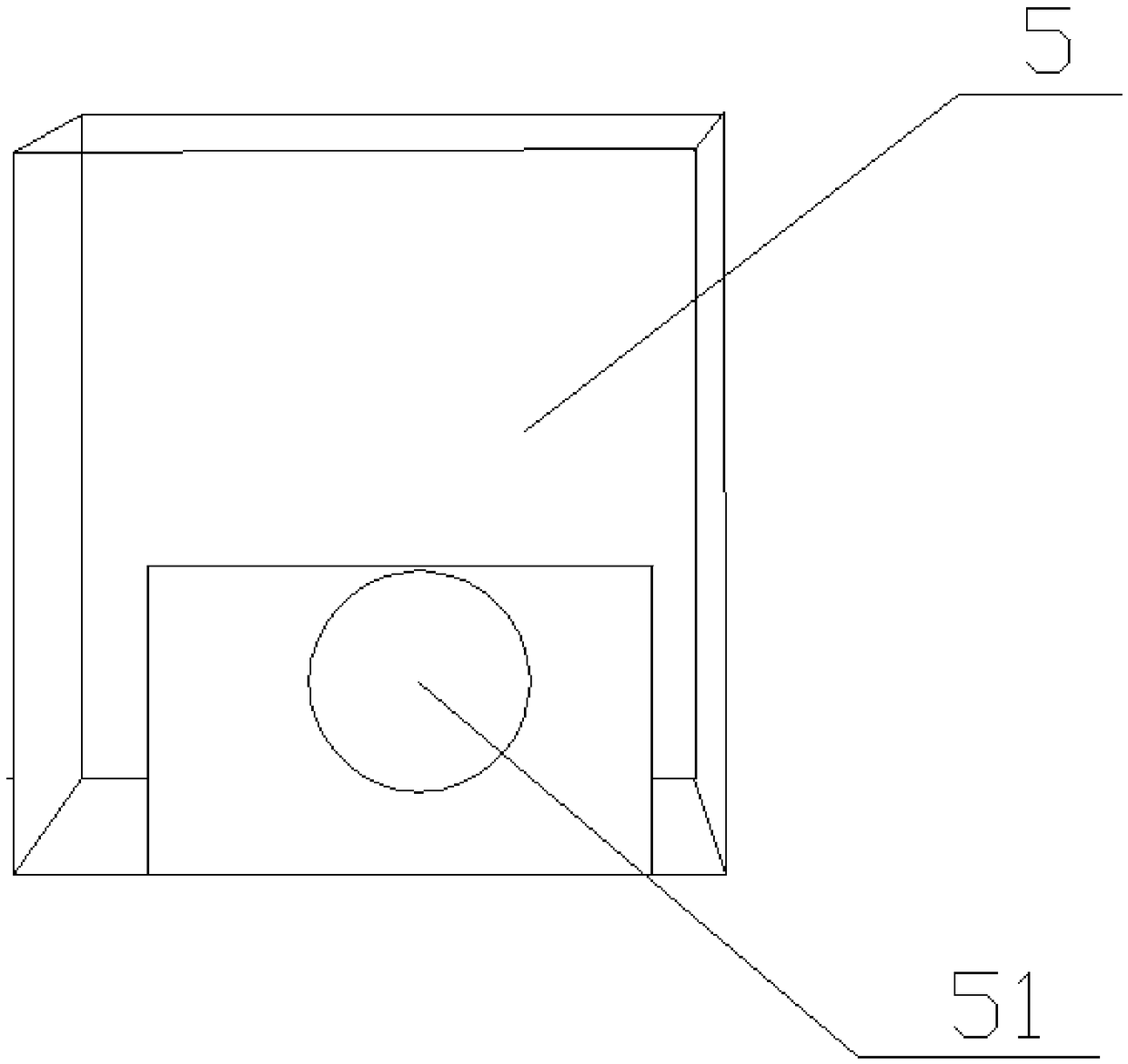

[0020] Such as figure 1 As shown, the fully automatic outfitting airless spraying equipment robot of the present application includes a frame 1, on which a support seat 2, a spraying machine 4 and a controller 5 are arranged, and a walking drive is arranged on the lower part of the frame 1 Motor 3 and traveling wheel 6, and traveling wheel 6 is connected with traveling drive motor 3 transmission; On support base 2, be provided with rotating mechanism, be connected with mechanical arm mechanism on rotating mechanism, be provided with spray gun 7 at the front end of mechanical arm mechanism, spray gun 7 is connected with the sprayer 4 through a high-pressure hose; a camera 8 is arranged on the mechanical arm mechanism, and the travel drive motor 3 and the sprayer 4 are respectively connected with the controller 5, controlled by the controller 5, and the controller 5 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com