Silver rhodanide/polyacid nano composite material preparation method

A nanocomposite material, silver cyanide technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of further improving the catalytic performance of silver-based photocatalytic materials and the preparation of silver-based photocatalytic materials The process is complex, silver-based photocatalysts are susceptible to photoetching and other problems, and it is suitable for large-scale industrial production, the preparation method and process are simple, and the effect of high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 0.1g of sodium thiocyanide and 0.05g of phosphomolybdic acid into 30mL of water, and dissolve to form solution A. Solution B was formed by adding 0.2 g of silver nitrate to 10 mL of water. Solution B was added to solution A and reacted for 3h. Then the product was washed with water three times, and dried in a vacuum oven at 80° C. for 12 h.

[0026] Depend on figure 1 According to the XRD pattern, the crystal structure of the silver thiocyanide / polyacid nanocomposite is mainly silver thiocyanide. Depend on figure 2 It can be seen from the scanning electron microscope image that its morphology is nanoparticles.

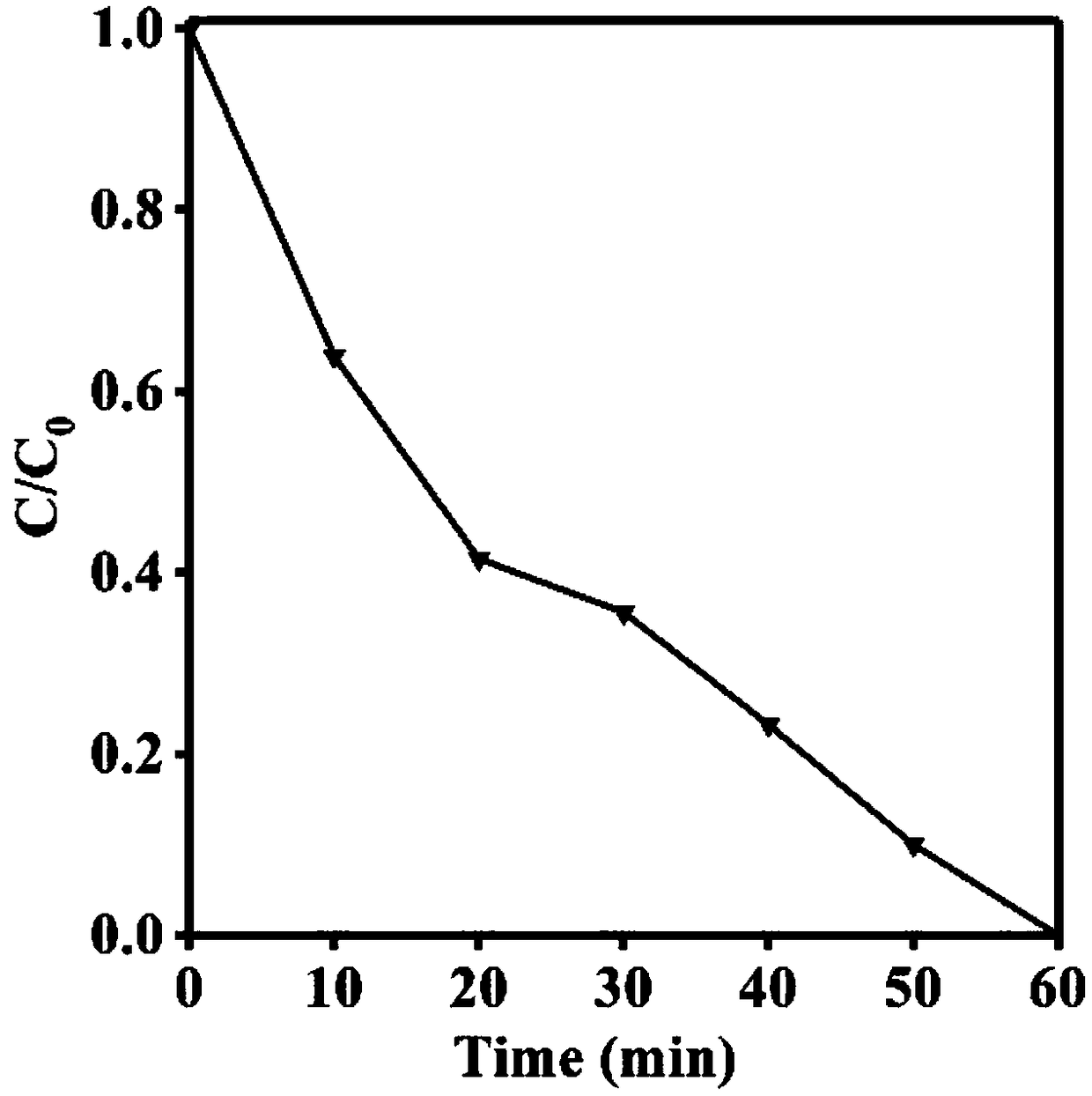

[0027] Add 0.05g silver thiocyanide / multi-acid composite material to 100mL rhodamine B solution or methylene blue solution (concentration is 5mg / L), after stirring in the dark for 30min, add 0.5mL hydrogen peroxide (concentration is 30wt%) to degrade experiment. Depend on image 3 The degradation of rhodamine B shows that the silver thiocyanide / polya...

Embodiment 2

[0029] As described in Example 1, the difference is that ammonium hydrosulfide and phosphotungstic acid are added. The resulting silver thiocyanide / polyacid composite nanomaterials can degrade rhodamine B up to 100% in 60 minutes.

Embodiment 3

[0031] As described in Example 1, except that potassium thiocyanate and ammonium phosphomolybdate were added. The resulting silver thiocyanide / polyacid composite nanomaterials can degrade rhodamine B up to 100% in 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com