Servo motor control method and system based on fractional iterative learning

An iterative learning, servo motor technology, applied in control systems, vector control systems, motor generator control and other directions, can solve the problems of following error fluctuations, low real-time performance, and insufficient reliability, and achieve high real-time performance and high reliability. , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the description. For the step numbers in the embodiment of the present invention, it is only set for the convenience of explanation and description, and there is no limitation on the order of the steps. The execution order of each step in the embodiment can be carried out according to the understanding of those skilled in the art Adaptive adjustment.

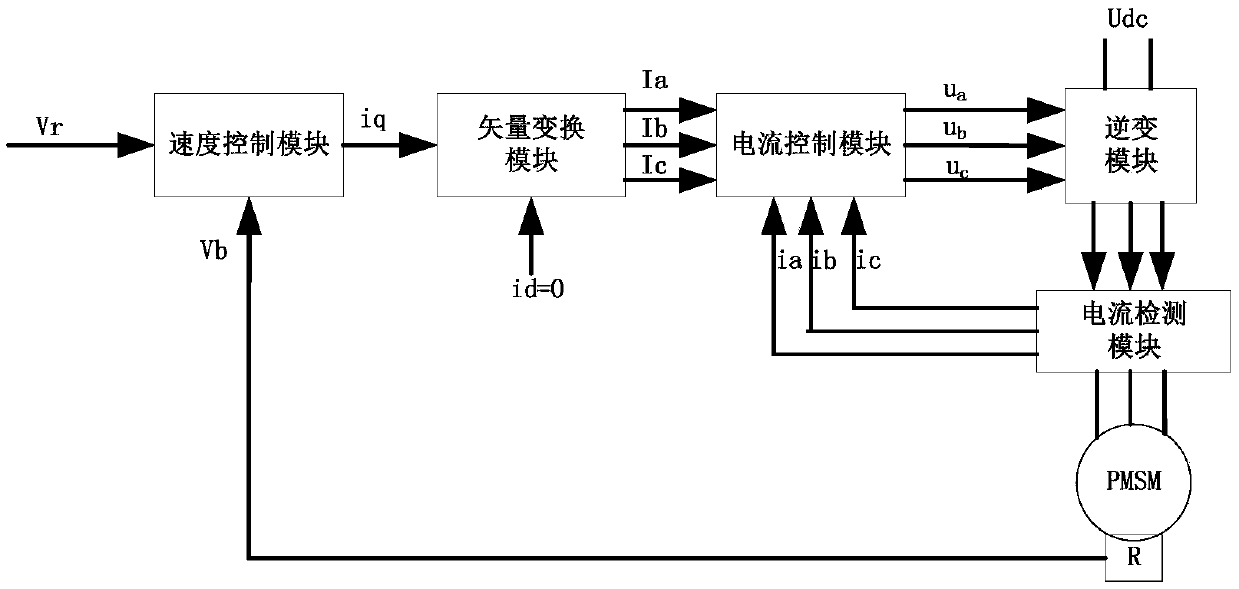

[0055] refer to figure 1 , the present invention is based on the servomotor control method of fractional order iterative learning, comprises the following steps:

[0056] The fractional order iterative learning algorithm is used to track the set motor running speed value to obtain the speed control amount;

[0057] The coordinate transformation of the speed control quantity is carried out by the matrix transformation method, and the three-phase current control value of the motor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com