Praseodymium indium zinc oxide thin film transistor and preparation method thereof

A technology of oxide thin film and praseodymium indium zinc, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of difficult flexible devices, poorly flexible substrates, process transfer temperature resistance characteristics, etc., to achieve short time consumption, Effect of high current switching ratio and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

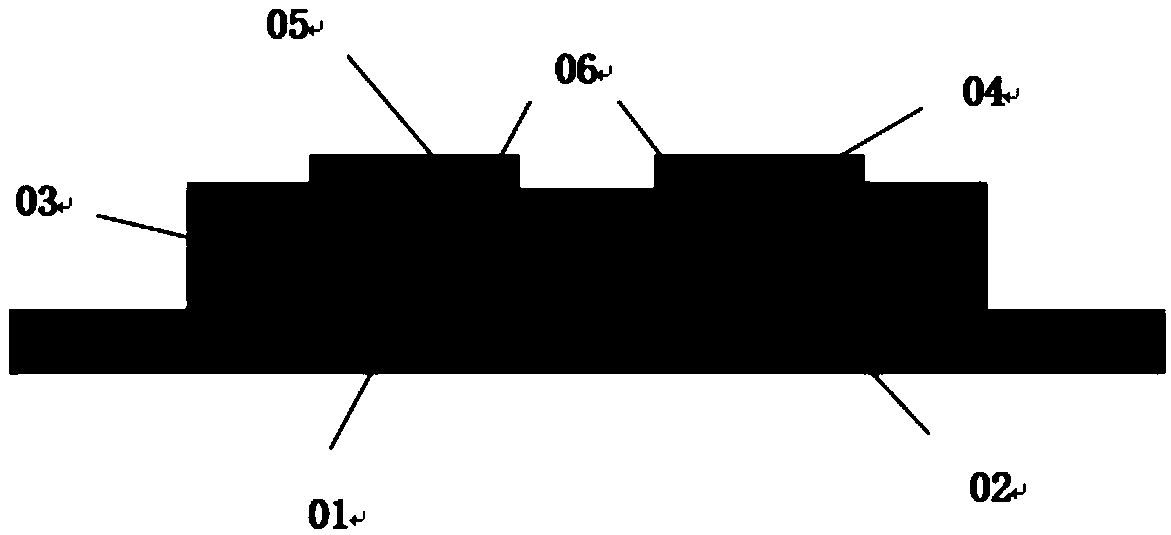

[0027] A praseodymium indium zinc oxide thin film transistor of this embodiment is prepared by the following method:

[0028] (1) Deposit a 300nm Al metal film on a glass substrate by DC sputtering at room temperature and pattern it with a mask as a gate;

[0029] (2) Oxidize 200nm Al in the gate to Al by anodic oxidation at room temperature 2 o 3 as a gate insulating layer;

[0030] (3) prepare the Pr-IZO semiconductor active layer by radio frequency sputtering at room temperature, the composition ratio of each material in the praseodymium indium zinc oxide (Pr 2 o 3 :In 2 o 3 : ZnO wt.%) is 3.9%: 86.4%: 9.7%. The total sputtering pressure is 3mtorr, and the sputtering atmosphere is Ar / O 2 =100 / 5 mixed gas, the radio frequency power supply is 80W, and the sputtering time is 129s; the thickness of the Pr-IZO semiconductor active layer obtained is about 6nm;

[0031] (4) Preparation of ultra-thin Al on the upper surface of the Pr-IZO semiconductor active layer by radio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com