Recovery and utilization method of separated substances of coke-oven gas

A coke oven gas and coke oven technology, applied in the field of energy conservation and environmental protection in the coking industry, can solve the problems of increased processing difficulty and cost, loss of raw gas emission, environmental pollution, etc., and achieve the goal of improving the quality of the atmospheric environment, reducing blockage, and improving tar quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

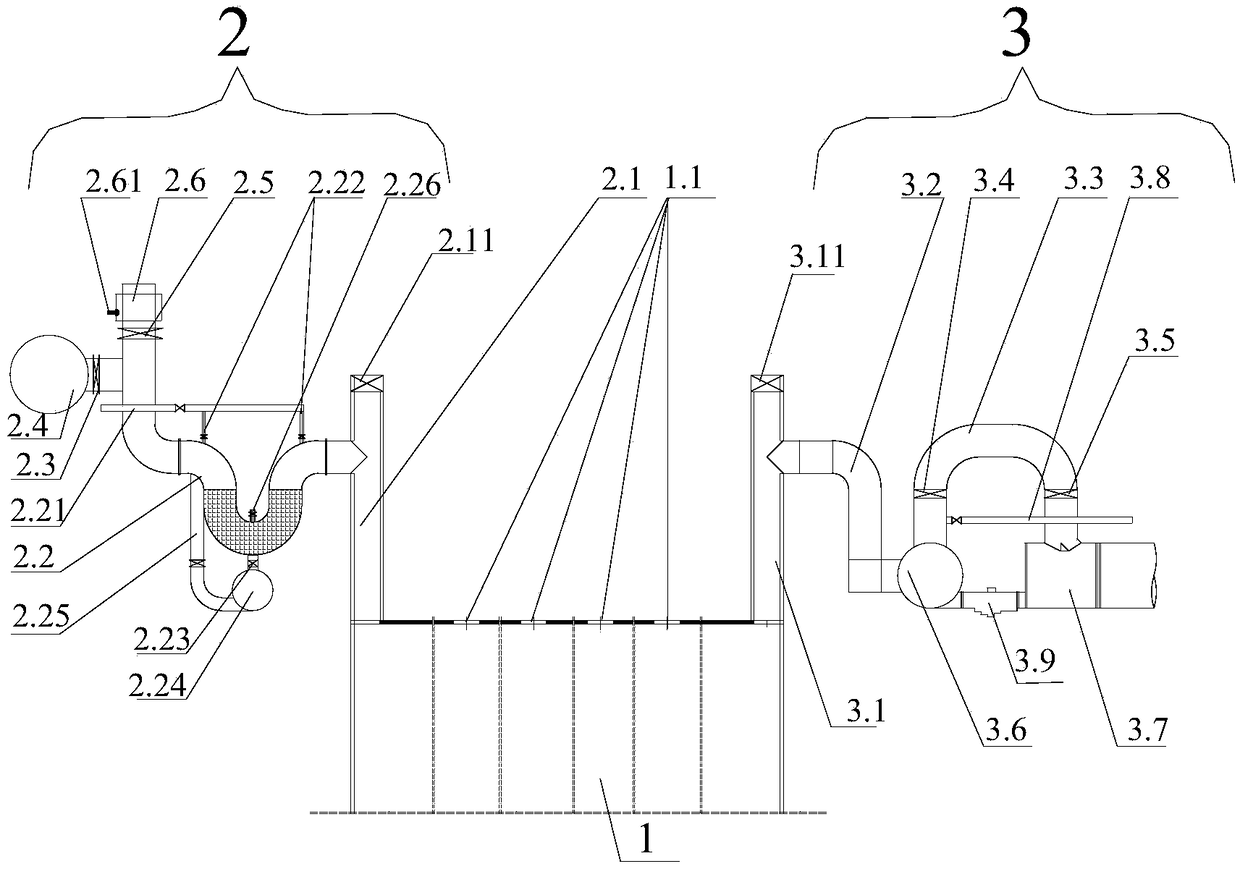

[0054] Each coke oven of the present invention includes several coke oven carbonization chambers and coke oven combustion chambers, and the coke oven carbonization chambers and coke oven combustion chambers are distributed alternately, ensuring that a a coke oven combustion chamber; and each coke oven coking chamber is provided with a coke-side coke oven gas recovery system and a machine-side coke oven gas recovery system.

[0055] Such as figure 1 As shown, this embodiment discloses a coke oven gas separation and recovery utilization system, which includes a coke oven carbonization chamber 1, a coke-side coke oven gas recovery system 2 and a machine-side coke oven respectively arranged at both ends of the coke oven carbonization chamber 1 Gas recovery system 3, wherein, the coke-side coke oven gas recovery system 2 is set on the coke side, and the coke oven gas recovery system 3 is set on the machine side; the top of the coke oven carbonization chamber 1 is provided with seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com